Vacuum electroosmosis curing water supply plant sludge device and use method thereof

A water supply plant sludge and electroosmosis technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of waste of power resources and human resources, reduce dehydration rate and efficiency, slow electroosmosis, etc., and achieve dehydration rate The effects of increasing slowly, increasing interface resistance, and increasing current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

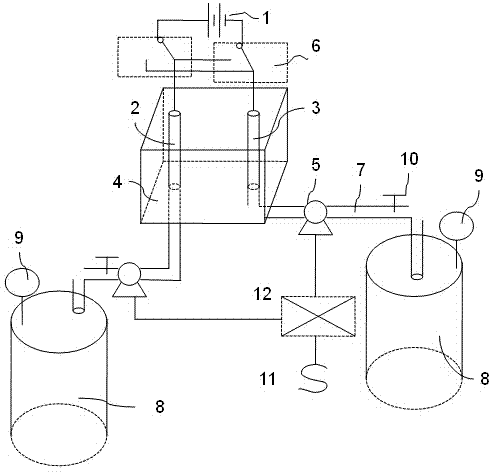

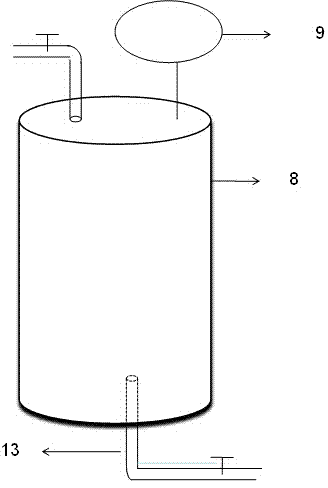

[0040] Such as Figure 1~3 As shown, a vacuum electroosmotic solidification device for sludge in a water supply plant includes a DC power supply 1, a sludge tank 4, a timing switch 12, a vacuum tank 8 and a SPDT switch 6, and the SPDT switch 6 passes through a wire and a DC power supply 1 Connection, by changing the contact mode of the single-pole double-throw switch 6, the current direction of the DC power supply 1 can be switched, and the positive and negative electrodes can be switched. Vacuum pumps 5 are connected to timing switch 12, and AC power supply 11 is connected to control the opening and closing of timing switch 12. Timing switch 12 is used to control the opening time of vacuum pump 5 and the time interval between two openings to discharge the enriched moisture. A vacuum gauge 9 is arranged above the vacuum tank 8 , and a drain pipe 13 is provided at the bottom of the vacuum tank 8 .

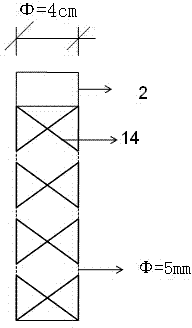

[0041] The sludge tank 4 is provided with a cathode metal 2 and an anode metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com