Composite metal coalescent filter element

A composite metal and coalescence technology, which is applied in the direction of filtration separation, liquid separation, chemical instruments and methods, etc., can solve the problem of unsatisfactory temperature resistance of the coalescing filter element, and achieve convenient replacement of components and maintenance, wide application range, and aggregation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

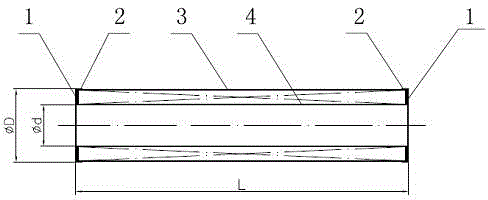

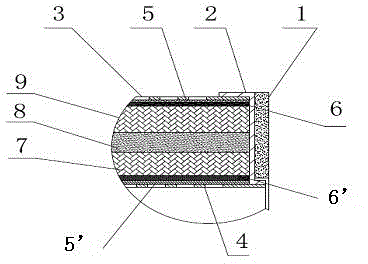

[0026] as attached figure 1 Schematic diagram of composite metal coalescing filter core structure and attachment of the present invention figure 2 As shown in the partial enlarged cross-sectional schematic diagram:

[0027] A composite metal coalescing filter element has an inner skeleton 4 and an outer skeleton 3, the material of the coalescing filter element is coated on the outer circumference of the inner skeleton 4, and is sleeved in the outer skeleton 3, and its two ends are as figure 2 As shown, it is sealed by the gasket 1 and the end cap 2, and the coalescing filter element materials are in order from the inner skeleton 4 to the outer skeleton 3: inner wire mesh 5', inner flow distribution layer 6', polar stainless steel broken Emulsion layer 7, coalescing layer 8 of polar stainless steel, collection layer 9, outer flow layer 6, outer wire mesh 5.

[0028] The metal is stainless steel.

[0029] On the basis of the above aspects, the inner and outer flow layers ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com