Method and System for Precluding Air Pollution in Industrial Facilities

a technology for industrial facilities and air pollution, applied in the direction of electrolysis components, electrolysis processes, etc., can solve the problems of increasing the pressure inside the volume, increasing the electrical energy requirements, and increasing the risk of production losses and hazards, so as to reduce the electric energy requirements, reduce the loss of thermal energy, and minimize the effect of suction energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

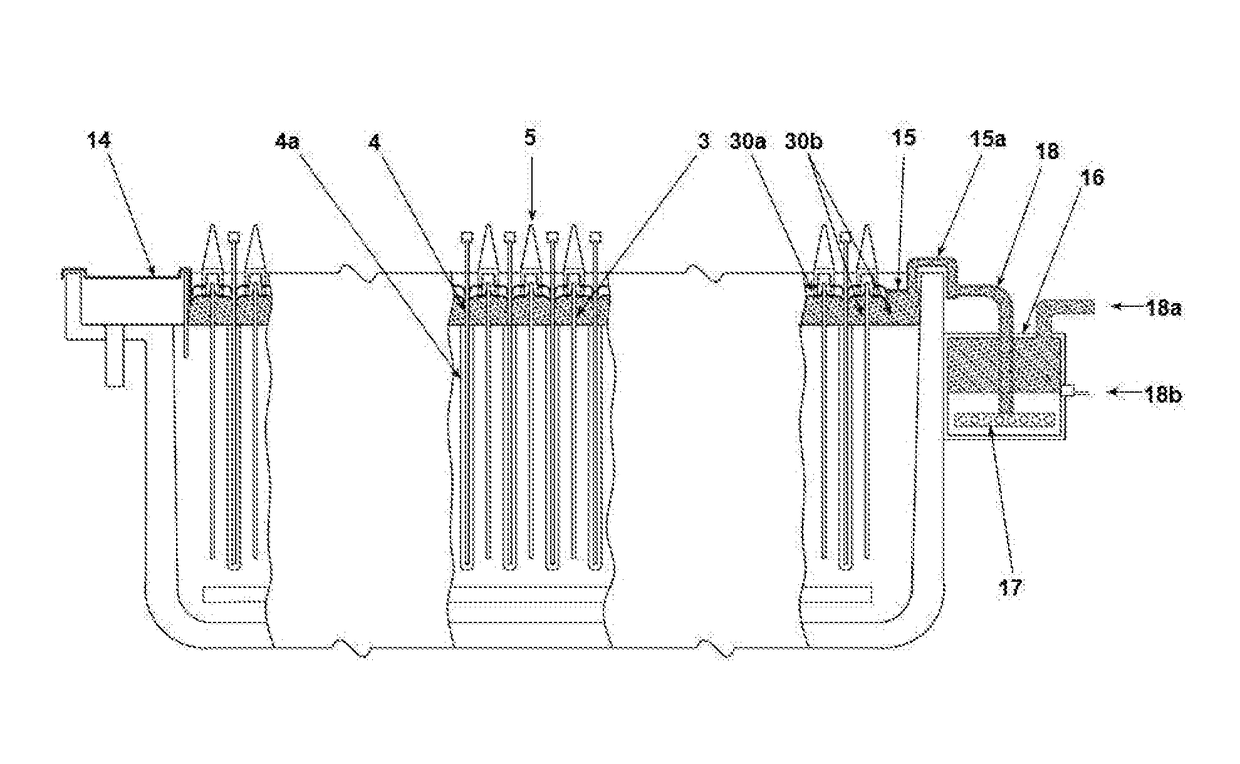

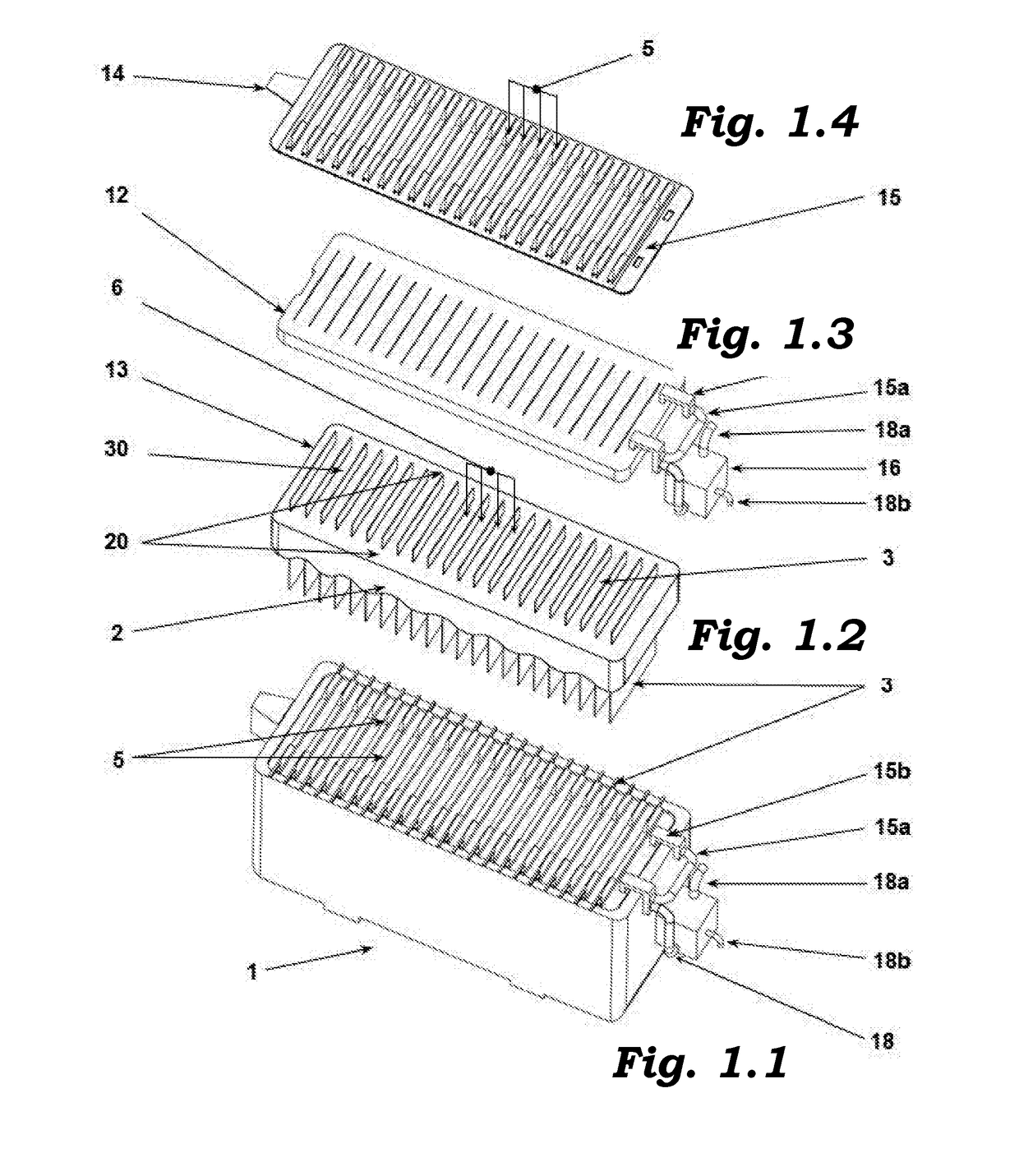

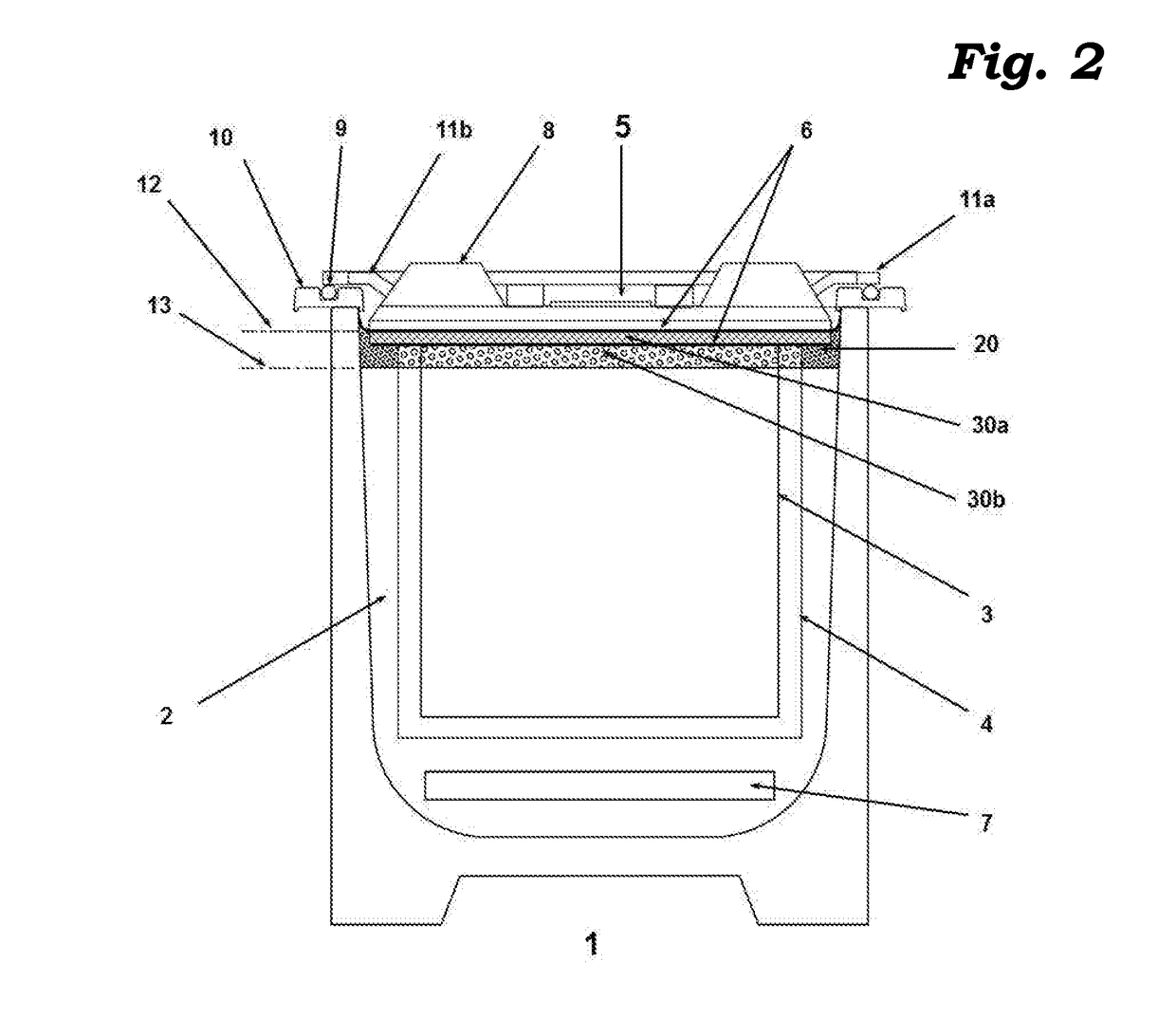

[0050]The invention relates to a method and a system for precluding contaminants / pollutants from polluting the air in working ambient that is typically contaminated as a result of carrying out certain industrial processes. Several concepts are combined in a novel manner leading to elimination of contaminants from the air. The invention as disclosed was implemented in a copper electrowinning facility to remove sulfuric pollutants that typically contaminate the air in working areas within the industrial facilities. Implementations of the invention as disclosed can be adapted to rid air of contaminants in a variety of industries using the teaching of the invention and without burden. Therefore, in the following description, numerous specific details are set forth to provide a more thorough description of the invention. It will be apparent, however, to one skilled in the pertinent art, that the invention may be practiced without these specific details. In other instances, well known fea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com