Polyurethane-acrylic ester composite emulsion and preparation method thereof

An acrylate and composite emulsion technology, applied in the direction of coating, can solve the problems of low chemical corrosion resistance, chemical resistance, solvent and water resistance on the surface of the paint film, and achieve improved application performance and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

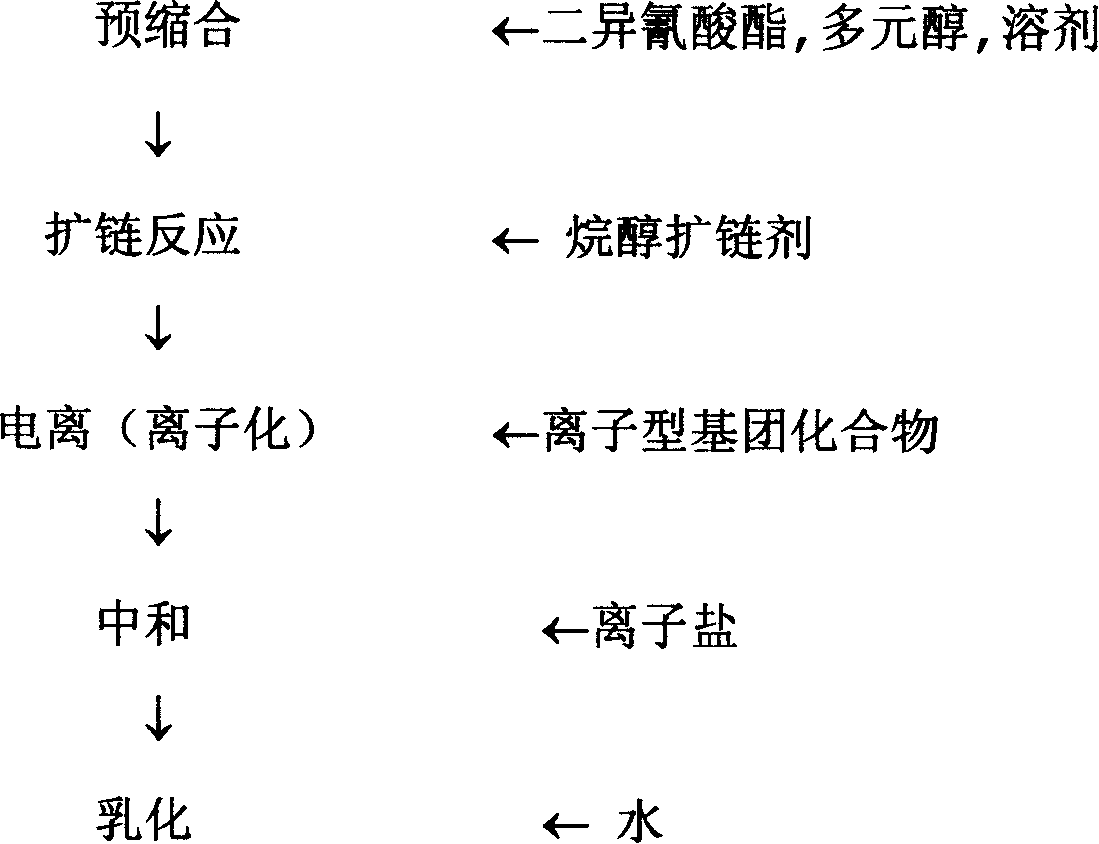

Method used

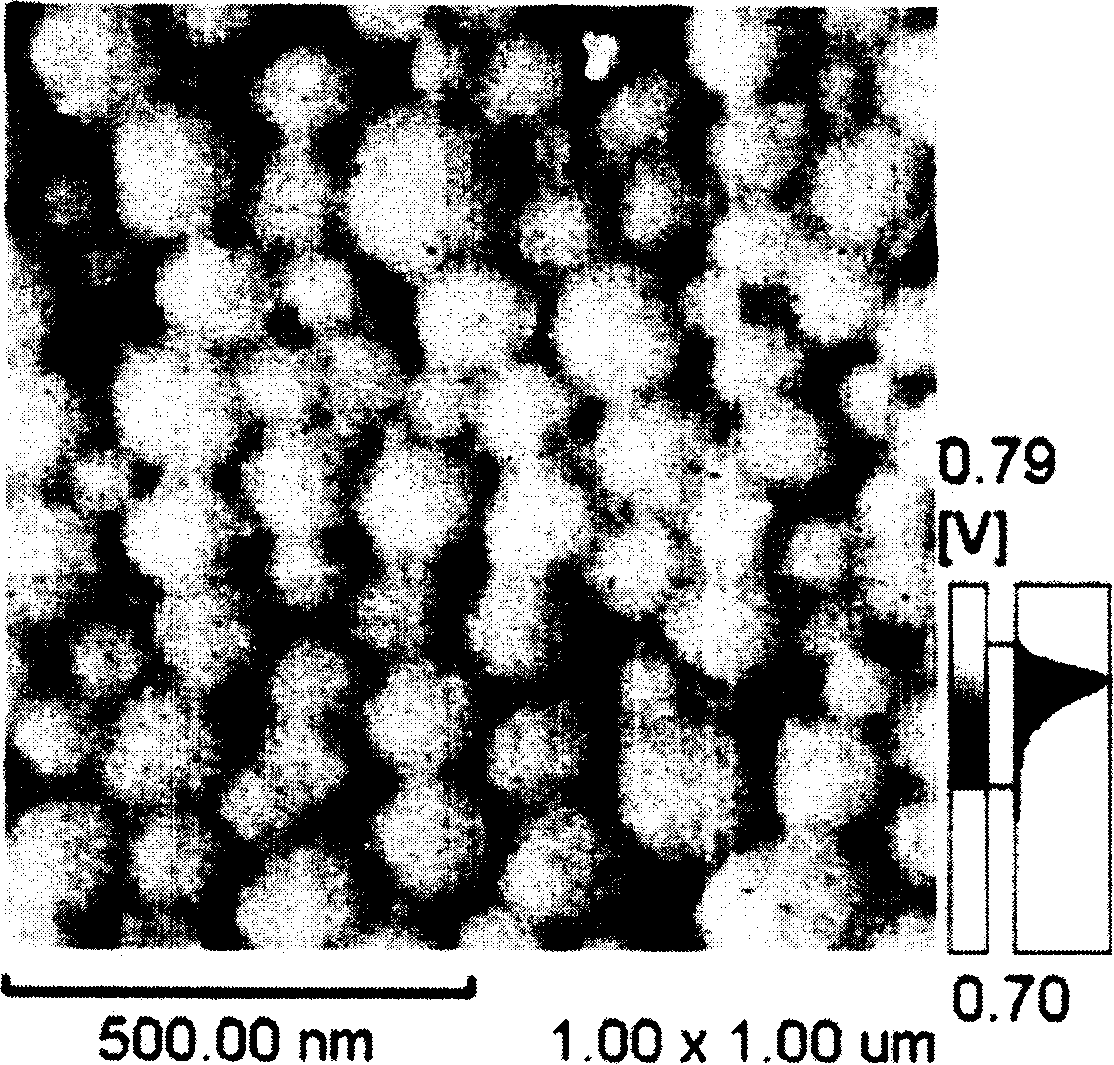

Image

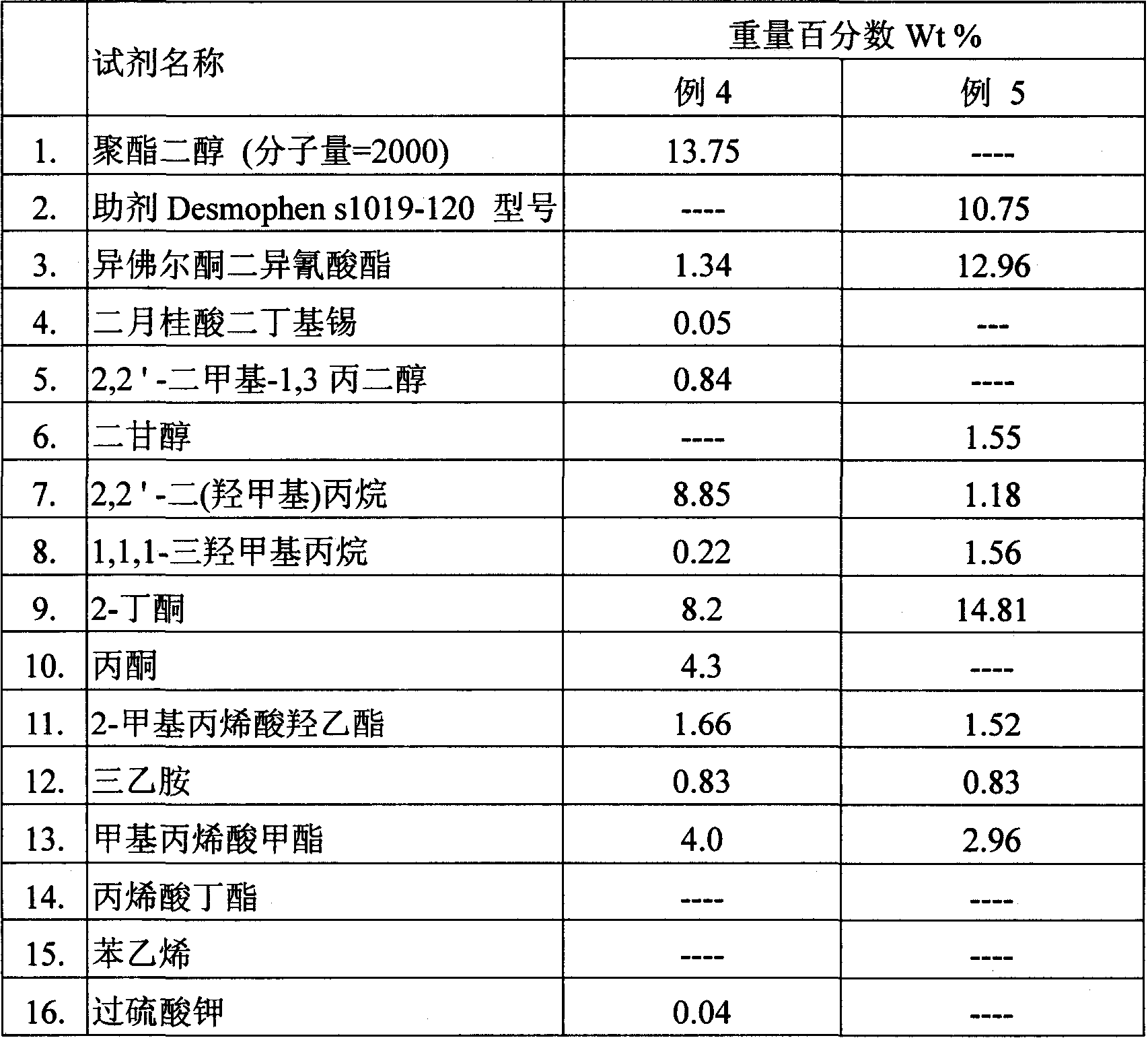

Examples

preparation example Construction

[0025] In the preparation step of the present invention, if necessary in the process of preparing the water-soluble polyurethane seed emulsion, acetone or ketone vacuum distillation is used to obtain the final water-soluble polyurethane seed emulsion.

[0026] Polyols or diols are used in the reaction, and the amount is in excess of the ideal ratio of organic diisocyanate to form a polyurethane prepolymer with isocyanate end groups. The suitable dosage ratio is 1:1.1 to 1:6, preferably 1:1.5 to 1:4, and the best ratio is 1:1.5 to 1:3. Polyol or diol and diisocyanate should provide suitable Anionic dispersion into prepolymers. Before the aqueous emulsion is formed after adding the monomer and forming the prepolymer, there is at least one relatively unreactive side chain carboxyl ion group in the solution, which is used to neutralize the ion salt later. The ionic salt contains active hydrogen bonds and a tertiary amine group.

[0027] A mixture of carboxyl-containing water-dis...

Embodiment 1

20.0

[0045] in the first reaction vessel

[0046] The reaction vessel was dried under nitrogen for 1 hour. Add polycaprolactone diol (PCL) (molecular weight: 2000, HMDI (molecular weight: 262.35)) in the reaction vessel, add after adding dibutyltin dilaurate (DBTL, molecular weight: 631.56), organic tin acts as a catalyst to catalyze the reaction of isocyanate-hydroxyl. The reaction mixture was stirred continuously for 30 minutes at 94°C. The percentage of NCO groups measured by adding NMP (molecular weight 99.13) by titration was 11.6%. When the NCO group content was determined, NMP (molecular weight 99.13) was added, and then DMPA (molecular weight 99.13) was added. 134.13), the reaction mixture was maintained at 94° C. for 2.5 hours. The reaction mixture was cooled to 25° C. and BA (7) was added, followed by hexanediol diacrylate (9), followed by styrene (8). When the prepolymerized monomers were cooled to 25°C, triethylamine (TEA) was added with stirring.

...

Embodiment 2

60.0

[0052] in the first reaction vessel

[0053] The reaction vessel was dried under nitrogen for 15 minutes. Add polycaprolactone diol (PCL) (1) to the reaction vessel, and add HMDI after adding an organotin catalyst (dibutyltin dilaurate, 3). The organotin acts as a catalyst to catalyze the reaction of isocyanate-hydroxyl. The reaction mixture was continuously stirred at 94°C for 30 minutes. Add NMP (4). DMPA (5) was added immediately after NMP (6), and the reaction mixture was maintained at 94°C for 2.5 hours. When the prepolymerized monomers were cooled to 25°C, triethylamine TEA (10) was added with stirring.

[0054] in the second reaction vessel

[0055] Water was added under the condition of bubbling nitrogen and maintaining 25°C. (Obtained in step 1?) The reaction mixture was cooled to 25°C and BA (7) was added followed by hexanediol diacrylate (9) followed by styrene (8). AIBN (14) was slowly added to NMP (13) in a down funnel and mixed for 5 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com