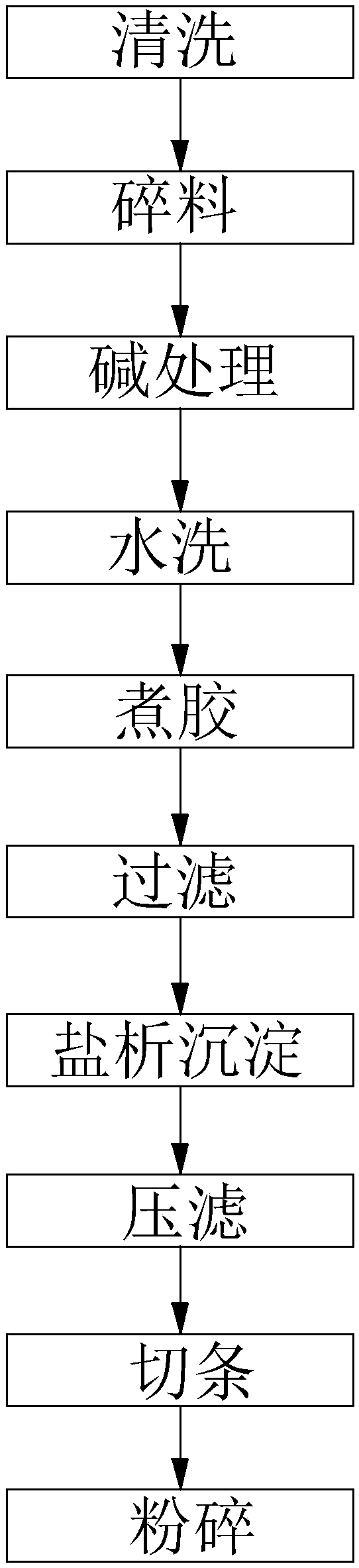

Automated Extraction Process of Carrageenan

An extraction process and carrageenan technology, which is applied in the field of automatic extraction of carrageenan, can solve the problems of difficulty in expanding production scale, inability to effectively treat wastewater, and difficult to guarantee product quality, etc. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

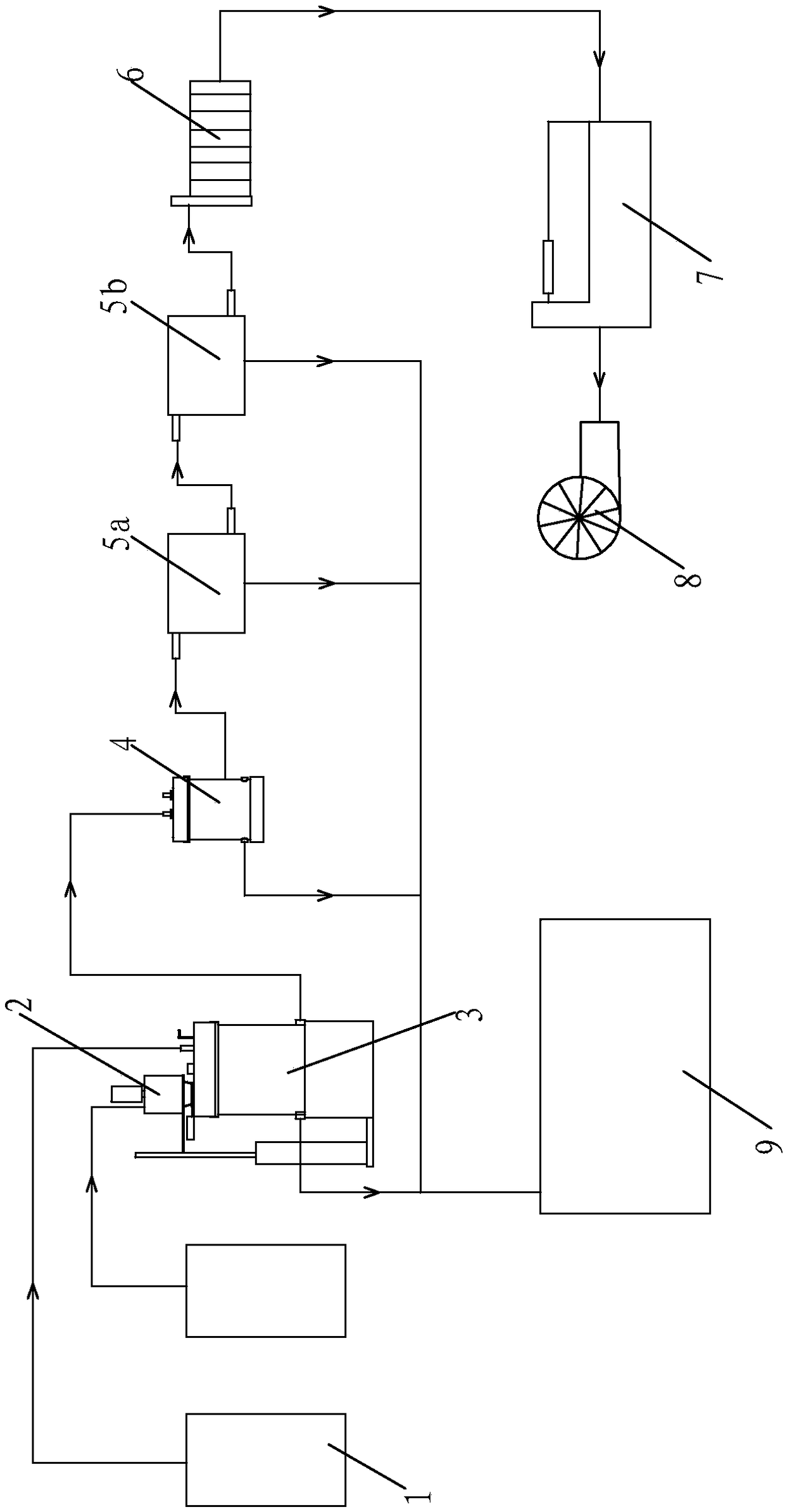

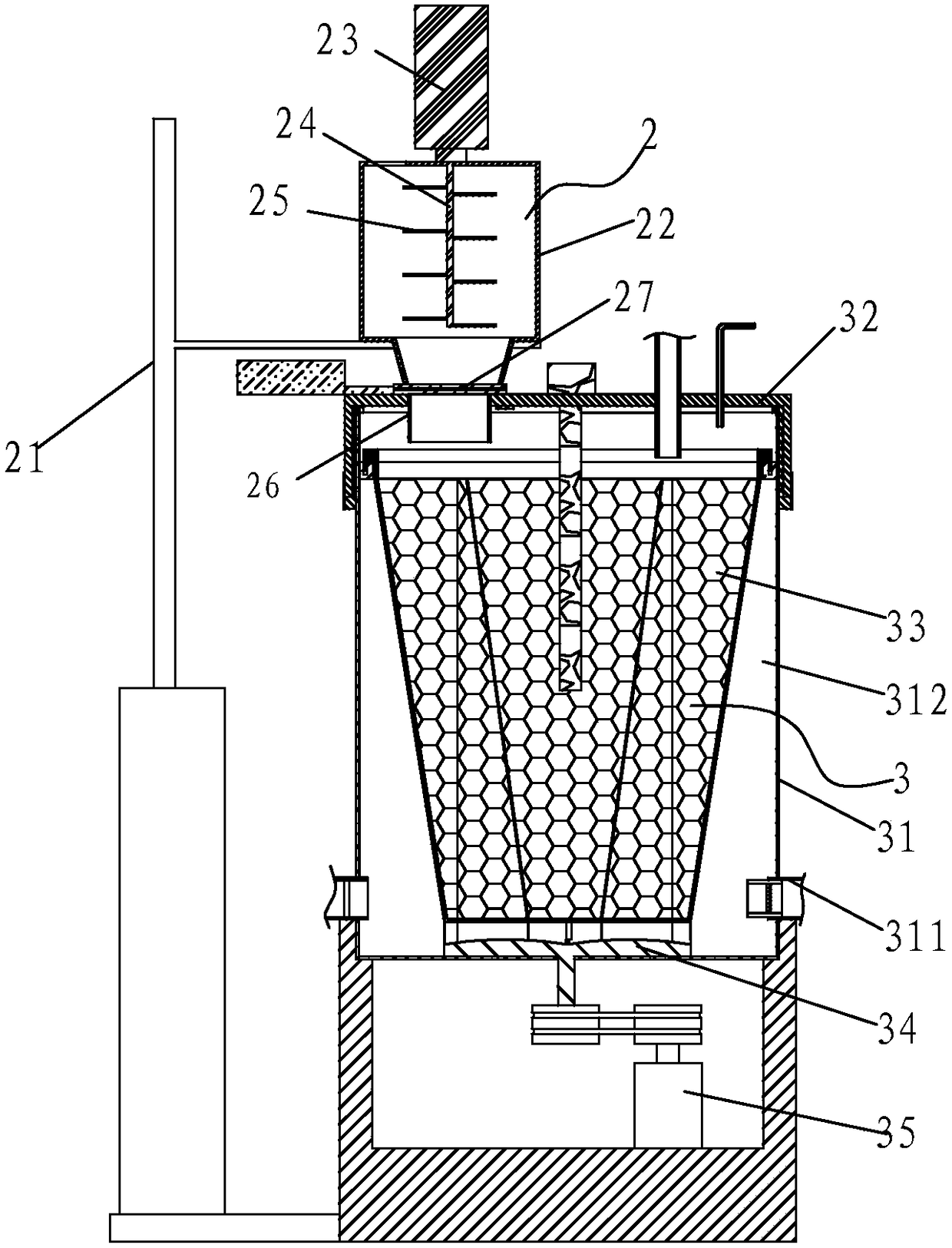

[0033] The invention discloses an automatic high-efficiency and environment-friendly carrageenan production line, such as Figure 1 to Figure 5 As shown, it includes a raw material tank 1, a crushing device 2, an alkali treatment device 3, a glue cooking device 4, a first plate and frame filter 5a, a second plate and frame filter 5b, a filter press 6, The strip cutting device 7 and the pulverizer 8 ; the alkali treatment device 3 , the gelatinization device 4 , the first plate and frame filter 5 a and the second plate and frame filter 5 b are all connected with a sewage treatment device 9 .

[0034] The crushing device 2 is installed on the top of the alkali treatment device 3 through a height-adjustable bracket 21, the crushing device 2 extends into the alkali processing device 3, and the raw materials crushed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com