Preparation method for layered aluminum-based neutron absorption plate

A neutron-absorbing plate, aluminum-based technology, applied in shielding, nuclear engineering, reactors, etc., can solve problems such as cracking of metal matrix composites, difficulty in preparing plates, and poor plasticity of metal matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with accompanying drawing:

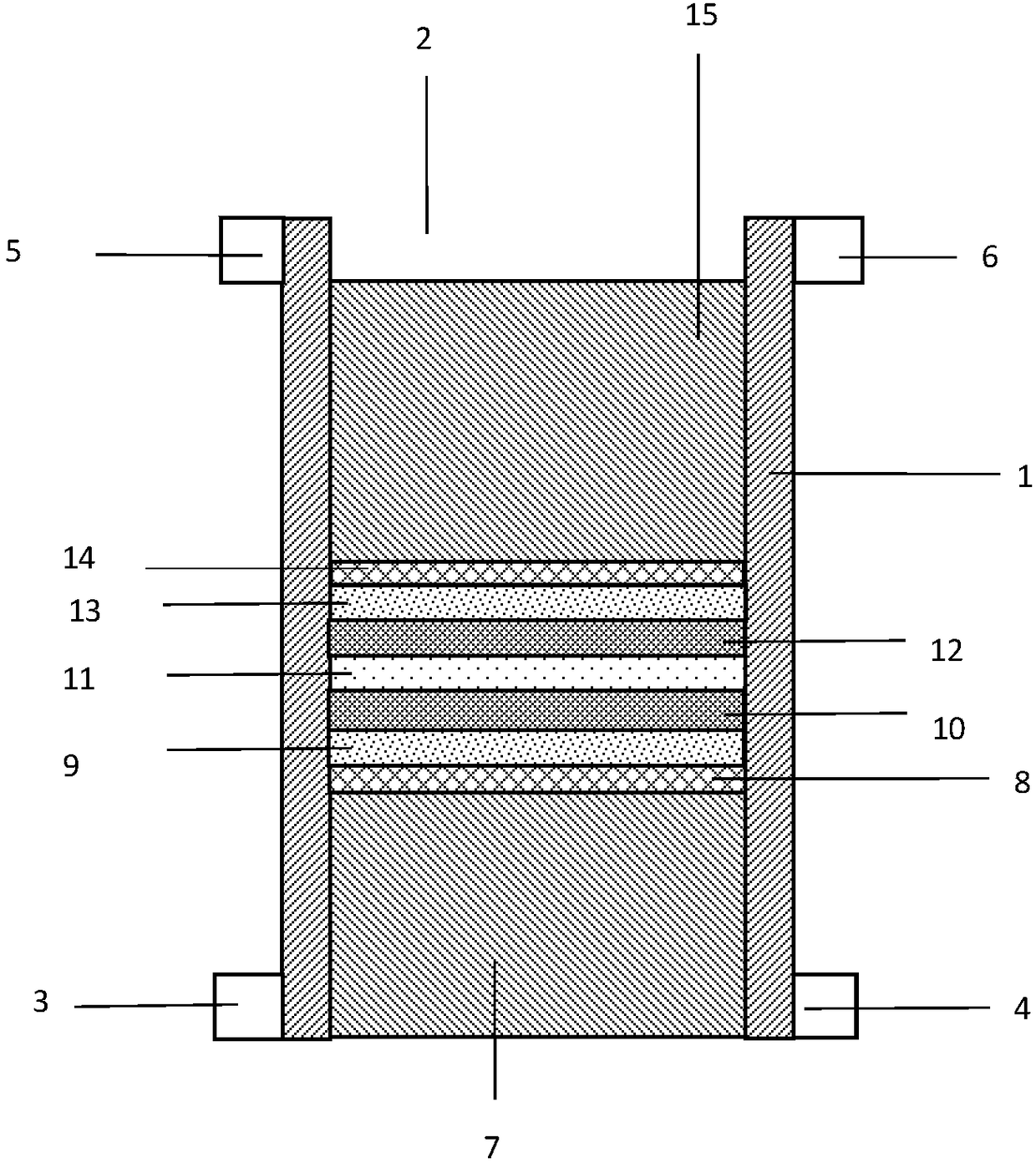

[0059] figure 1 As shown, it is a diagram of the loading state of the layered aluminum-based neutron absorbing material. The frame 6 is assembled and fixed, and the inside is the cavity 2; the bottom of the cavity 2 is a graphite pad 7, and the first graphite paper layer 8, the first mixed fine powder layer 9, and the first carbon fiber layer are sequentially laid on the top of the graphite pad 7 10. The aluminum alloy powder layer 11, the second carbon fiber layer 12, the second mixed fine powder layer 13, and the second graphite paper layer 14 are pressed by graphite pads 15 on the second graphite paper layer 14 top.

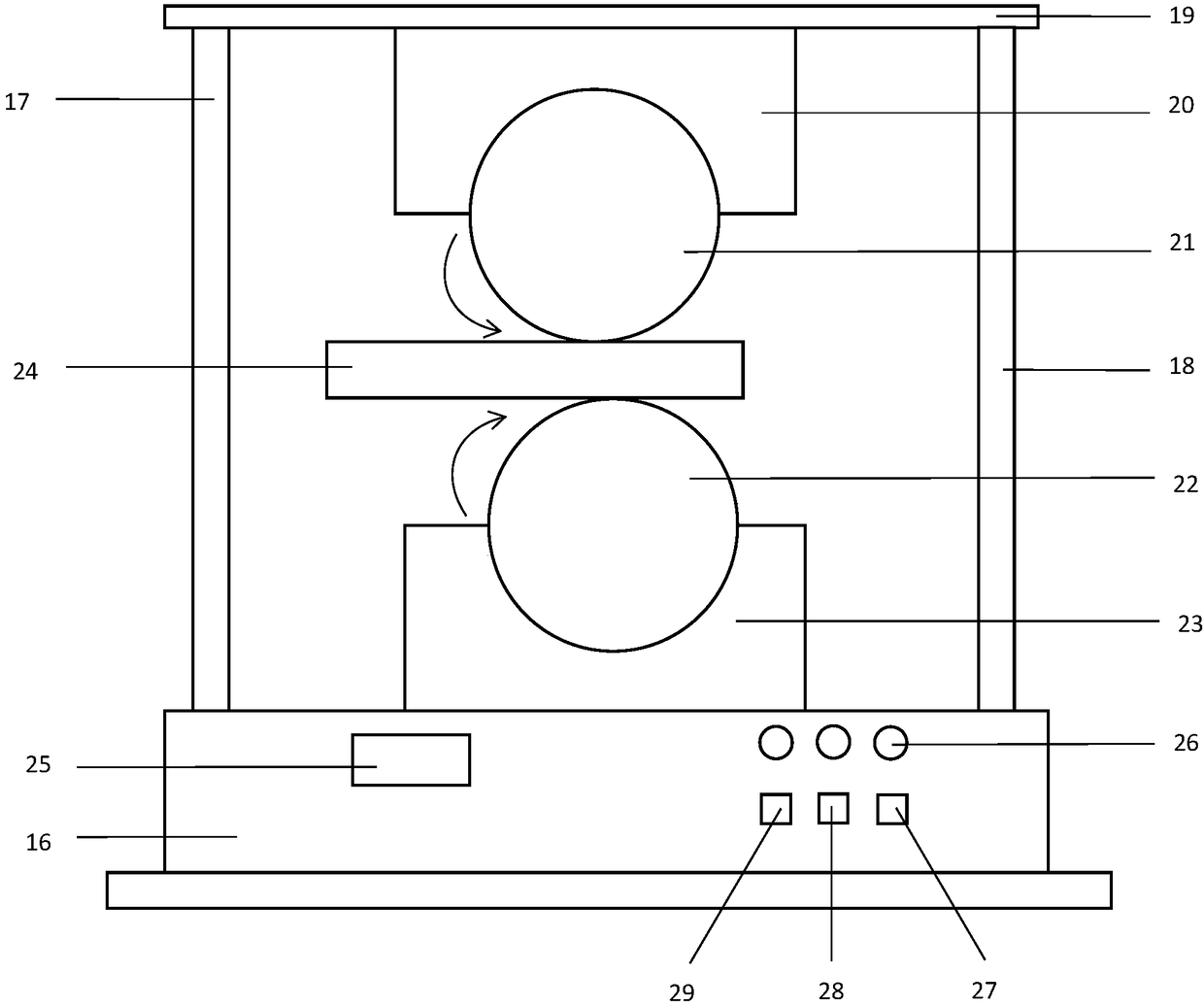

[0060] figure 2 As shown, it is the rolling state diagram of the layered aluminum-based neutron absorbing plate, and the position and connection relationship of each part must be correct and rolled in sequence.

[0061]The rolling mill is vertical, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com