Method for producing low-temperature cement clinker from straw ash

A technology for cement clinker and straw ash, which is applied in cement production and other directions to achieve the effect of reducing CO2 emissions, reducing pollution and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

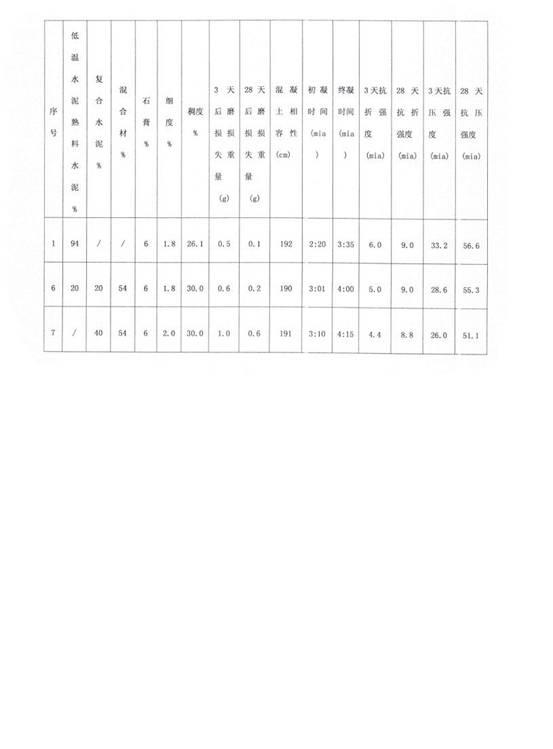

[0015] The low-temperature cement clinker produced from straw ash of the present invention is prepared through a special process with dry and wet straw ash as the main raw material and steel slag and aluminum slag as auxiliary materials. The production method includes the following steps:

[0016] 1) Raw material preparation: the raw materials are straw ash, steel slag and aluminum slag; the straw ash is fueled by various plant stalks such as rice straw, wheat straw, rice husk, corn stalk, soybean stalk, wood twigs, bark, etc. The dry and wet waste slag discharged after combustion and power generation is called straw ash. The steel slag used is the waste slag discharged from the iron and steel plant, and the sludge discharged after washing and magnetic separation to control the iron is called steel slag, which contains 50% CaO and about 8% moisture; Aluminum slag is the waste slag discharged from the production of aluminum sulfate in chemical plants, containing A 2 o 3 At abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com