Method for extracting platinum, rhodium and palladium from failed platinum alloy gauze

A platinum alloy, platinum-rhodium technology, applied in the field of purification and reuse, precious metal recovery, can solve the problems of separation, extraction difficulties, precious metal waste, loss and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

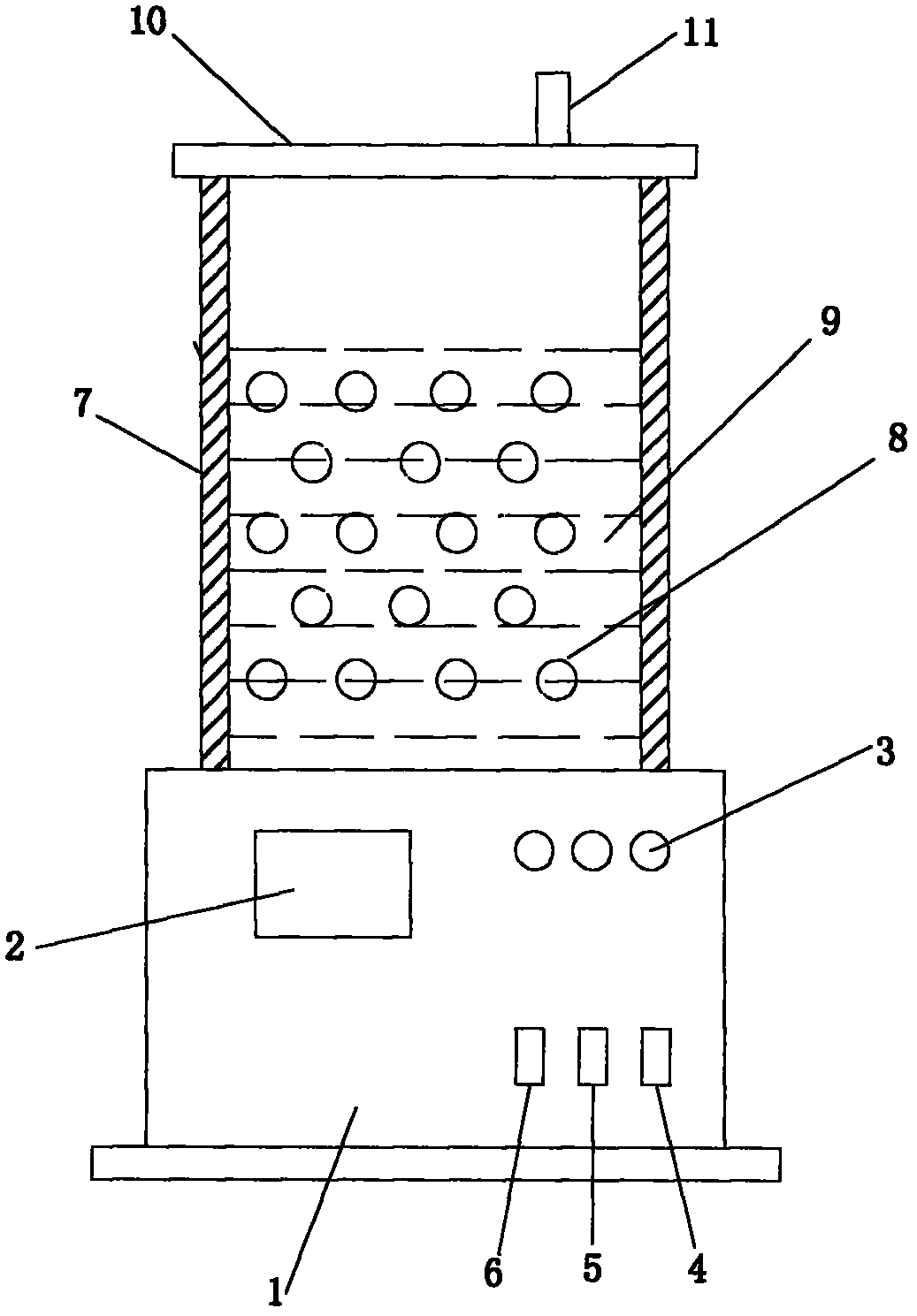

[0114] The present invention will be further described below in conjunction with accompanying drawing:

[0115] figure 1 For the heating and dissolution state diagram of the invalid platinum alloy mesh, the position of each part must be correct, the ratio should be proportioned, and the operations should be performed in sequence.

[0116] The amount of chemical substances used to extract platinum, rhodium, and palladium is determined according to a predetermined range, in grams, milliliters, millimeters 3 As a unit of measurement, when industrialized extraction, in kilograms, liters, meters 3 is the unit of measurement.

[0117] The heating and dissolving of the invalid platinum alloy mesh is carried out in a ceramic container. The invalid platinum alloy mesh 8 is placed in the ceramic container 7, and then hydrochloric acid + nitric acid solution 9 is added, and the hydrochloric acid + nitric acid solution 9 will submerge the invalid platinum alloy mesh 8. The upper part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com