Preparation method of aluminum base gadolinium oxide neutron absorbing plate

A neutron absorbing plate and gadolinia-based technology, which is applied in the field of preparation of aluminum-based gadolinium oxide neutron absorbing plate, can solve problems such as poor neutron absorption performance, increased brittleness, and poor corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with accompanying drawing:

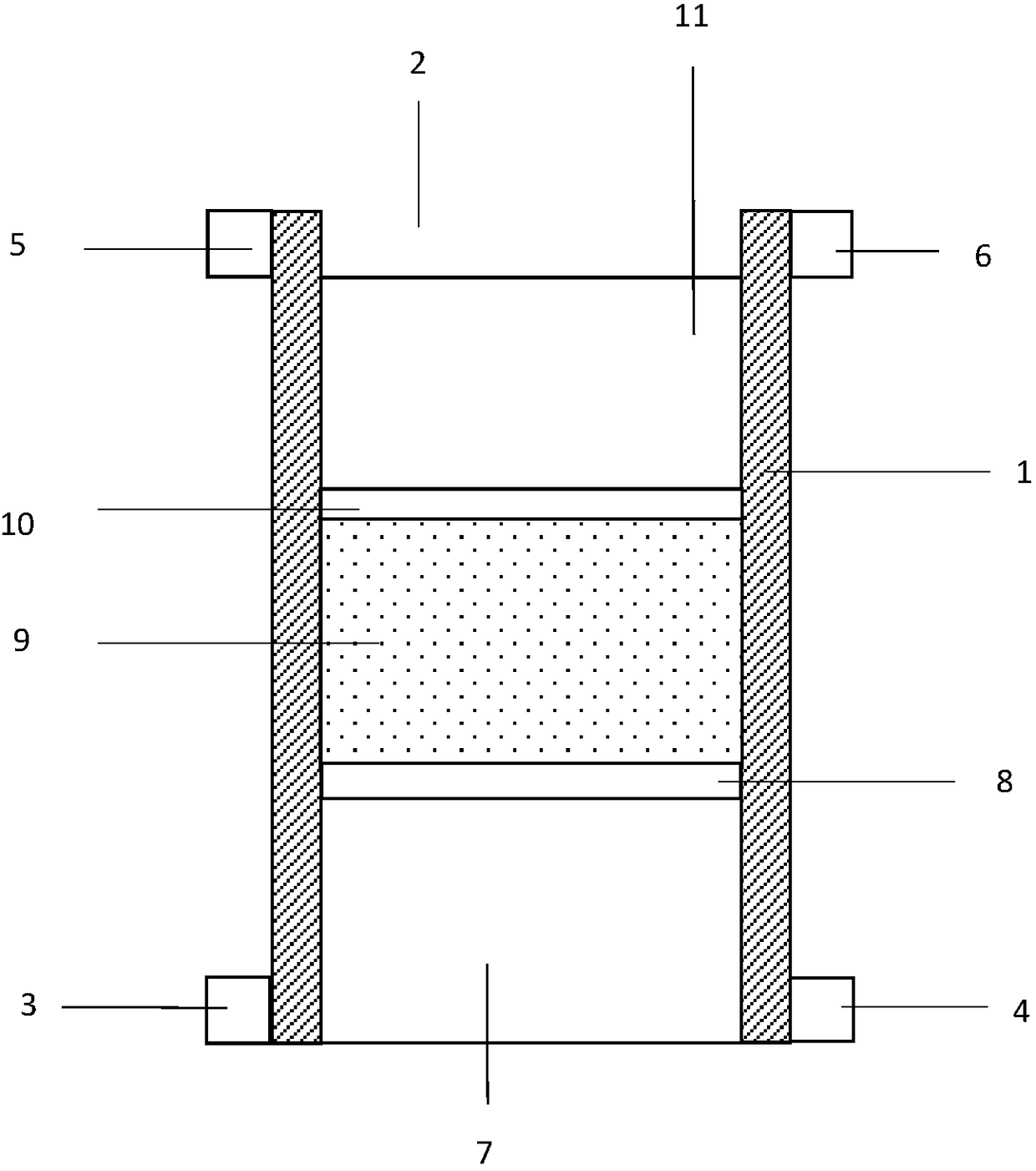

[0066] figure 1 As shown, it is a state diagram of aluminum-based gadolinium oxide mixed fine powder mold loading, the open-close mold 1 is rectangular, and consists of the first open-close frame 3, the second open-close frame 4, the third open-close frame 5, and the fourth open-close frame 6 Assembled and fixed, the inside of the open-close mold is the mold cavity 2, and the graphite pad 7 is placed at the bottom of the mold cavity 2, the first graphite paper 8 is placed on the top of the graphite pad 7, and the aluminum is placed on the top of the first graphite paper 8. Gadolinium oxide-based mixed fine powder 9, the second graphite paper 10 is on the top of the aluminum-based gadolinium oxide mixed fine powder 9, and the graphite compact 11 is on the top of the second graphite paper 10.

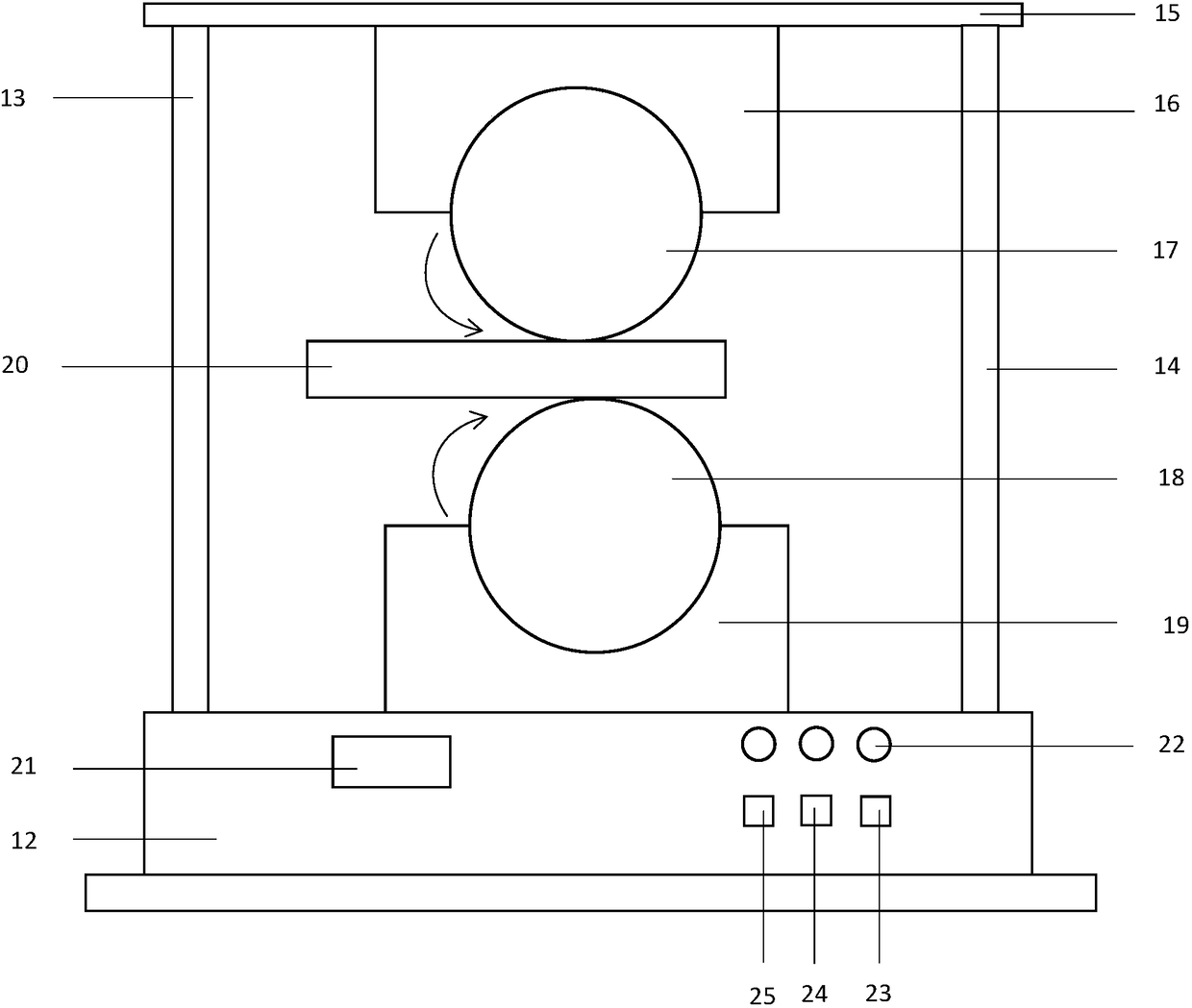

[0067] figure 2 As shown, it is the rolling state diagram of the aluminum-based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com