Mercerized denim manufacturing technique

A production process and technology of denim, applied in the field of textile production and mercerized denim production technology, can solve the problems of short penetration reaction time, little improvement in wearability, poor fabric wool effect, etc., and achieve high mercerized barium value, mercerized light transmission High core, advanced technology and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

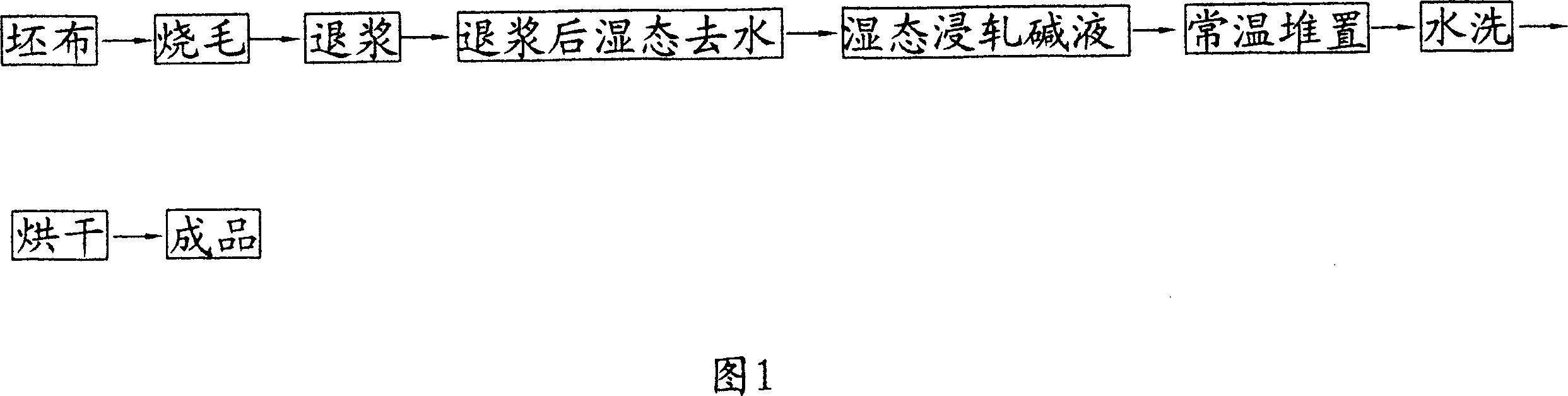

[0021] One of the specific embodiments is shown in Figure 1.

[0022] A production process of mercerized denim fabric, which uses yarn-dyed denim gray fabric as raw material, and its process steps include gray fabric singeing, desizing, mercerizing, drawing, and pre-shrinking, and the mercerizing is wet mercerizing. The said wet state mercerizing is mercerizing by padding lye and stacking at normal temperature, and its process steps include successively, after desizing, wet state dehydration, padding lye, stacking at normal temperature, washing and drying processes.

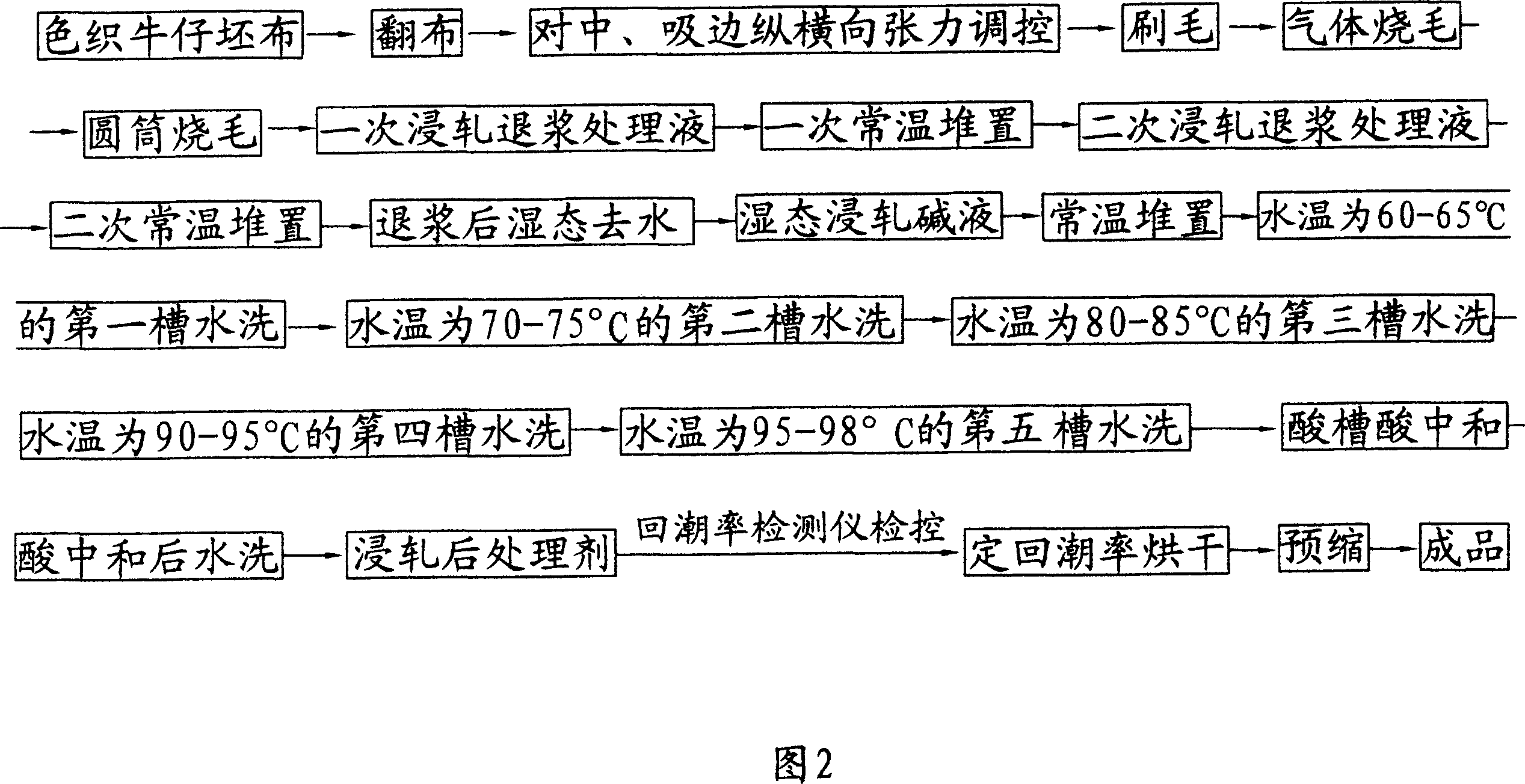

[0023] The second specific embodiment is shown in Figure 2.

[0024] A production process of mercerized denim fabric, which uses yarn-dyed denim gray fabric as raw material, and its process steps include gray fabric singeing, desizing, mercerizing, drawing, and pre-shrinking, and the mercerizing is wet mercerizing. And said wet state mercerizing is mercerizing by padding lye and stacking at normal temperature, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com