System for predicting fatigue limit of magnesium alloy member based on infrared thermal imaging, and method thereof

A fatigue limit, magnesium alloy technology, used in measuring devices, using repetitive force/pulse force to test material strength, instruments, etc., can solve problems such as wasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with specific embodiments.

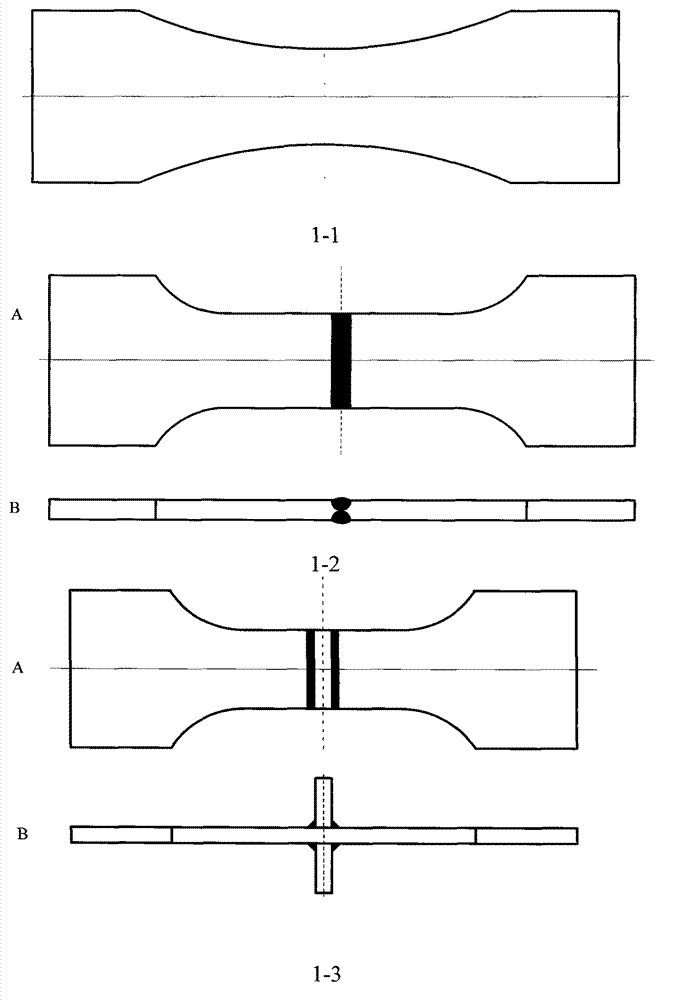

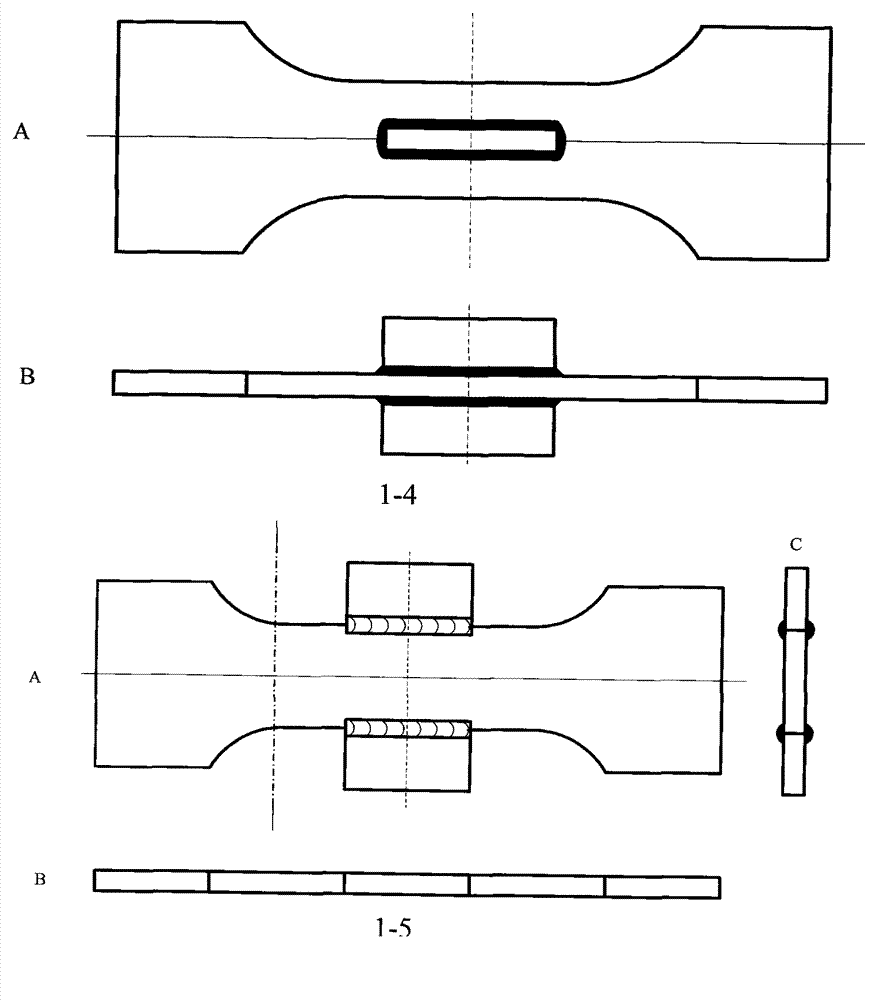

[0024] figure 1 As shown, the structural schematic diagram of the fatigue test piece designed to simulate the magnesium alloy component, in which 1-1 is the form of the base metal fatigue test piece, which is directly machined from the base metal sample, and 1-2 is the test piece form of the butt joint (A is the top view, B is the main view), 1-3 is the test piece form of the transverse cross joint (A is the top view, B is the main view), the sample is welded first and then machined into shape, 1-4 is the longitudinal non-cross joint The load-bearing cross joint (A is the top view, B is the main view), 1-5 shows the test piece form of the side connection joint (A is the top view, B is the main view, and C is the side view), the side connection joint and the longitudinal non-load-bearing cross The joints are machined first and then welded into shape.

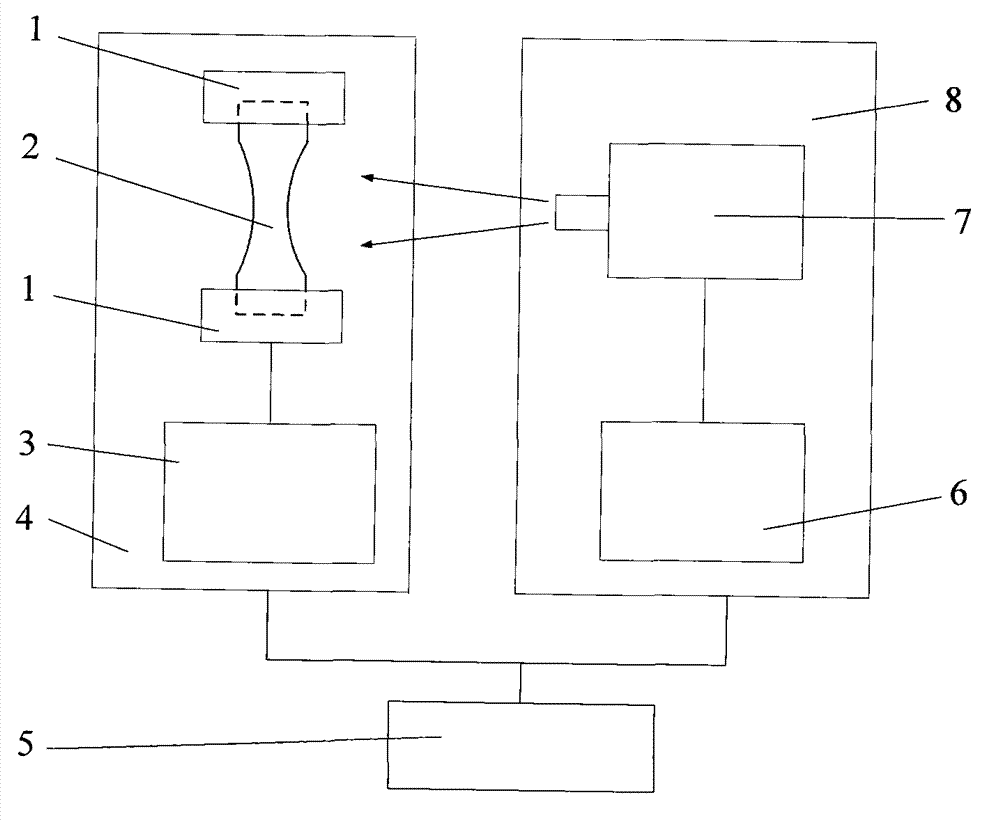

[0025] figure 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| fatigue limit | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com