Graphene/titanium dioxide composite porous material, preparation method and application thereof

A technology of titanium dioxide and porous materials, applied in the field of porous materials, can solve the problems of high experimental cost and high energy consumption, and achieve the effects of simple preparation method, simple preparation process and easy industrialized preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

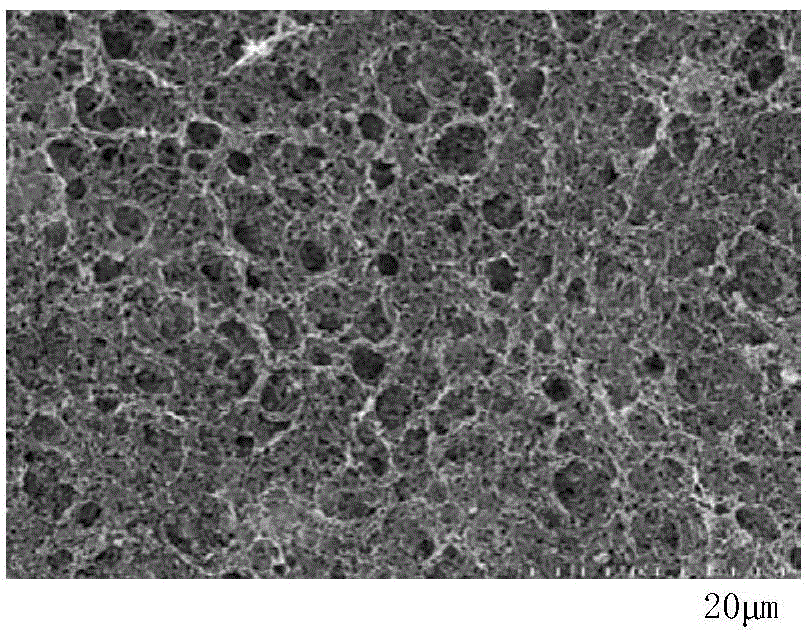

[0036] Prepare 10 mg / mL linear styrene-butadiene-styrene triblock polymer in butanone micelle solution and 0.5 mg / mL graphene oxide in N,N-dimethylformamide solution, and mix them in equal volume. uniform. Add titanium dioxide to the mixed solution, and ensure that its concentration is 5 mg / mL, and sonicate uniformly. The above mixed solution is cast on a glass carrier plate placed in a saturated atmosphere of a precipitant such as ethanol, and is kept at rest until the solution is completely volatilized to form a film. The membrane together with the conductive glass was calcined at 500 °C for 4 h in a nitrogen atmosphere to obtain a graphene / titania composite porous material. The prepared graphene-titania composite porous material together with the carrier plate was placed in liquid nitrogen for quenching, and after a few minutes, it was taken out and brittle fracture. The surface and section of the film were sprayed with gold and observed under an electron microscope.

[...

Embodiment 2

[0039] First, prepare 10 mg / mL styrene-isoprene block polymer solution in tetrahydrofuran and 0.5 mg / mL graphene oxide solution in N,N-dimethylformamide, and mix them in equal volumes. Subsequent experimental steps are the same as in Example 1.

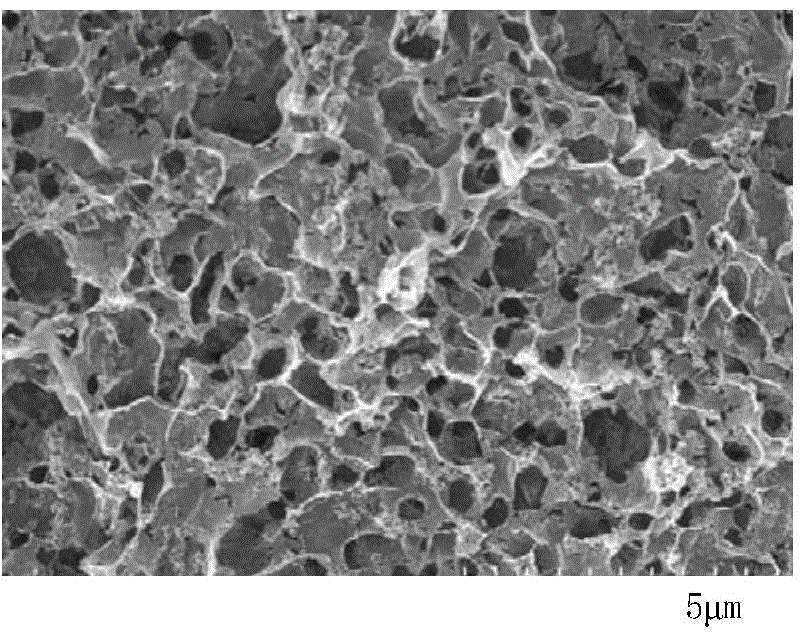

[0040] The scanning electron microscope picture of the graphene / titania composite porous material prepared by Example 2 is shown in figure 2 .

Embodiment 3

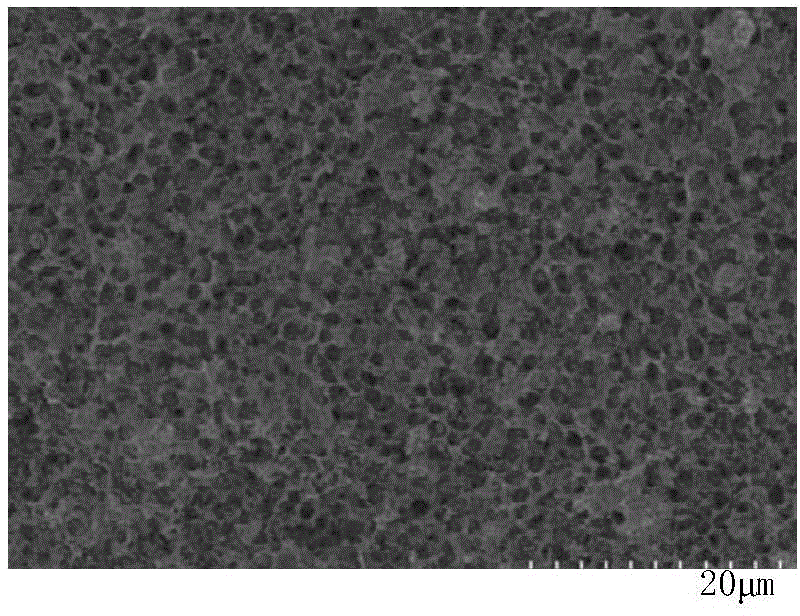

[0042] First, prepare a tetrahydrofuran solution of 20 mg / mL star-shaped styrene-butadiene-styrene triblock copolymer and a N,N-dimethylformamide solution of 2 mg / mL graphene oxide in a volume ratio of 1:2 Mix; then add nano-titanium dioxide, and ensure that its concentration is 10mg / mL, and then sonicate uniformly. The above mixed solution is cast on a glass carrier plate placed in a saturated atmosphere of a precipitating agent such as methanol, and is kept at rest until the solution is completely volatilized to form a film. Subsequent experimental steps are the same as in Example 1.

[0043] The scanning electron microscope picture of the graphene / titania composite porous material prepared by Example 3 is shown in image 3 and 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com