Core-shell-structure lightweight aggregate prepared by cold bonding method and preparation method thereof

A technology of core-shell structure and lightweight aggregate, which is applied in the field of core-shell structure lightweight aggregate and its preparation, can solve the problems of reducing the water absorption rate of ceramsite, concrete bursting, and deterioration of mechanical properties, so as to reduce the risk of cracking and shrinkage, and achieve good performance. Thermal insulation performance, thermal insulation performance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

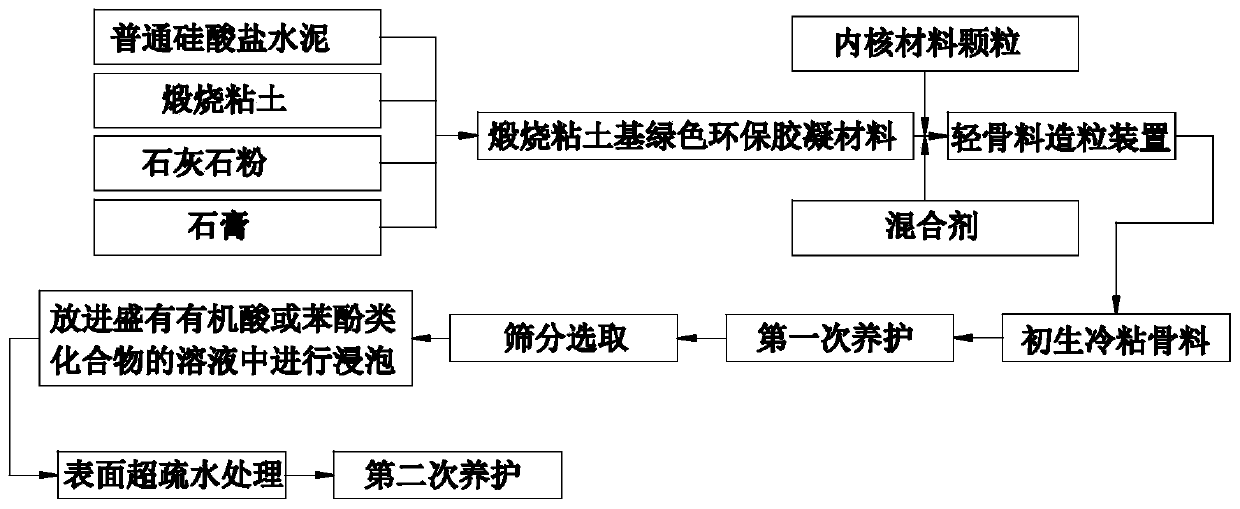

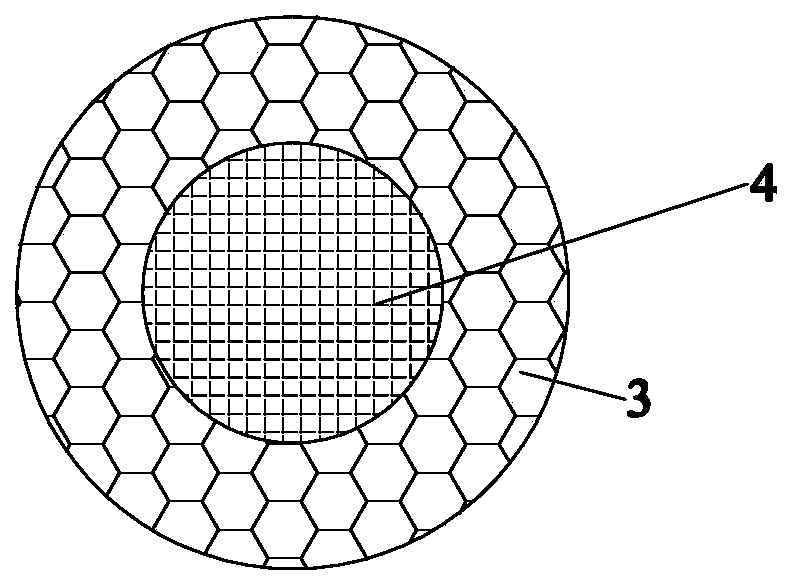

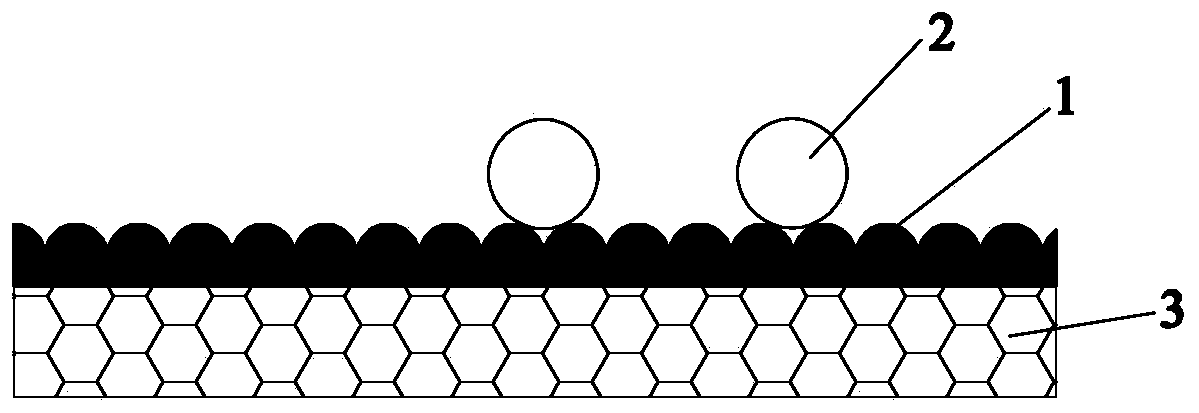

[0041] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, such as figure 1 As shown, the cold bonding method provided by the embodiment of the present invention prepares the production method of the core-shell structure lightweight aggregate, comprising: the following steps:

[0042] Ordinary Portland cement, calcined clay, limestone powder, and gypsum are configured in proportion, and these materials are dry-mixed into a calcined clay-based green and environmentally friendly gelling material; the calcined clay-based green and environmentally friendly gelling material is the cold The shell material of the core-shell structure lightweight aggregate was prepared by sticking method. In this embodiment, the dry mixing of the materials to form the calcined clay-based green environmental protection gelling material is realized by a stirrer. It should be noted that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com