Solid fermentation method of ansamitocin

A technology of solid fermentation and anisomycin, applied in microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve problems such as difficulties in industrial fermentation, and achieve the effects of simple sample processing and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

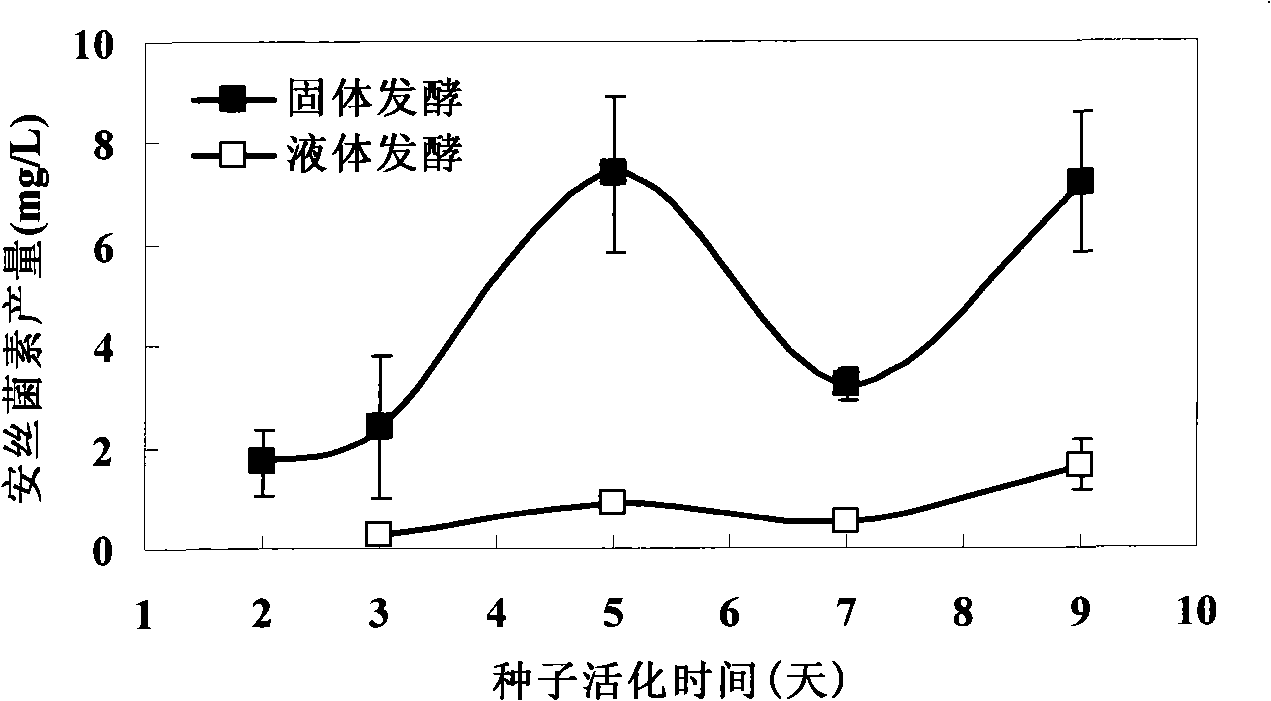

[0020] Comparison of the ansamitocin production of YMG medium solid fermentation and YMG medium liquid fermentation:

[0021] Seed and fermentation culture: the seed medium is YMG medium, and the weight percentage of its components is: 0.4% of yeast extract, 1% of maltose, 0.4% of glucose, 1.5% of agar powder and 96.7% of distilled water, and the diameter of the petri dish is 10cm. The filling volume is 15ml. Use the high-concentration thalline streak YMG medium plate preserved in 10.3% sucrose, activate it upside down at 28°C for 9 days, and inoculate it into a 250ml shake flask containing 30ml of YMG medium with an inoculation spatula, at 28°C, 220 RPM for 2 days, press 10 2 The inoculum amount of CFU / ml was spread on the YMG medium plate covered with the regenerated cellulose film support, and cultured at 28°C for 7 days. At the same time, the same inoculum amount was inoculated into a 250ml shaker containing 30ml of YMG medium with an inoculation spatula. In the bottle, ...

Embodiment 2

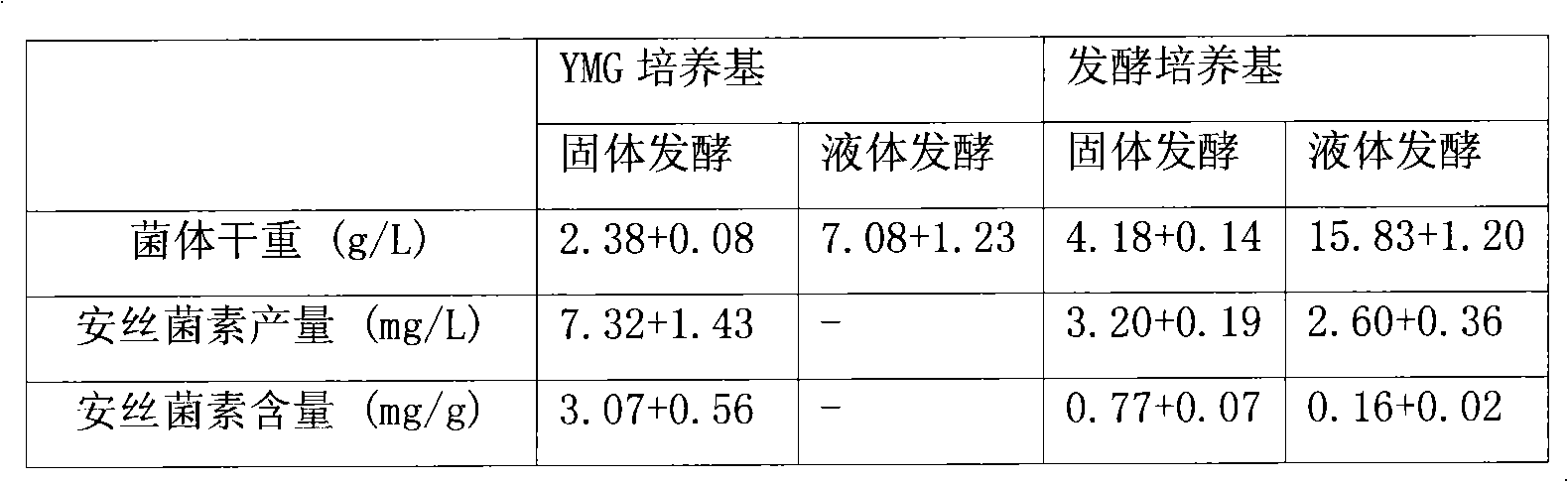

[0025] Comparison of solid-liquid fermentation production of ansamitocin with different media compositions using a renewable cellulose film support:

[0026] Seed culture: the seed medium is YMG medium, and the mass percentage of its components is: 0.4% of yeast extract, 1% of maltose, 0.4% of glucose, 1.5% of agar powder and 96.7% of distilled water. The diameter of the petri dish is 10cm. Liquid volume 15ml. 10.3% sucrose-preserved high-concentration thalline streaked YMG plate was activated upside down at 28°C for 5 days, inoculated into a 250ml shaker flask containing 30ml of YMG medium with an inoculation spatula, and cultured at 220 rpm at 28°C for 2 day, after serial dilution, with 10 6 The concentration of CFU / ml was spread on the YMG plate covered with regenerated cellulose film support, and cultured for 9 days at 28°C. At the same time, the same inoculum was inoculated into a 250ml shake flask containing 30ml of YMG medium, at 28°C, 28 Cultivate at 220 rpm for 9 da...

Embodiment 3

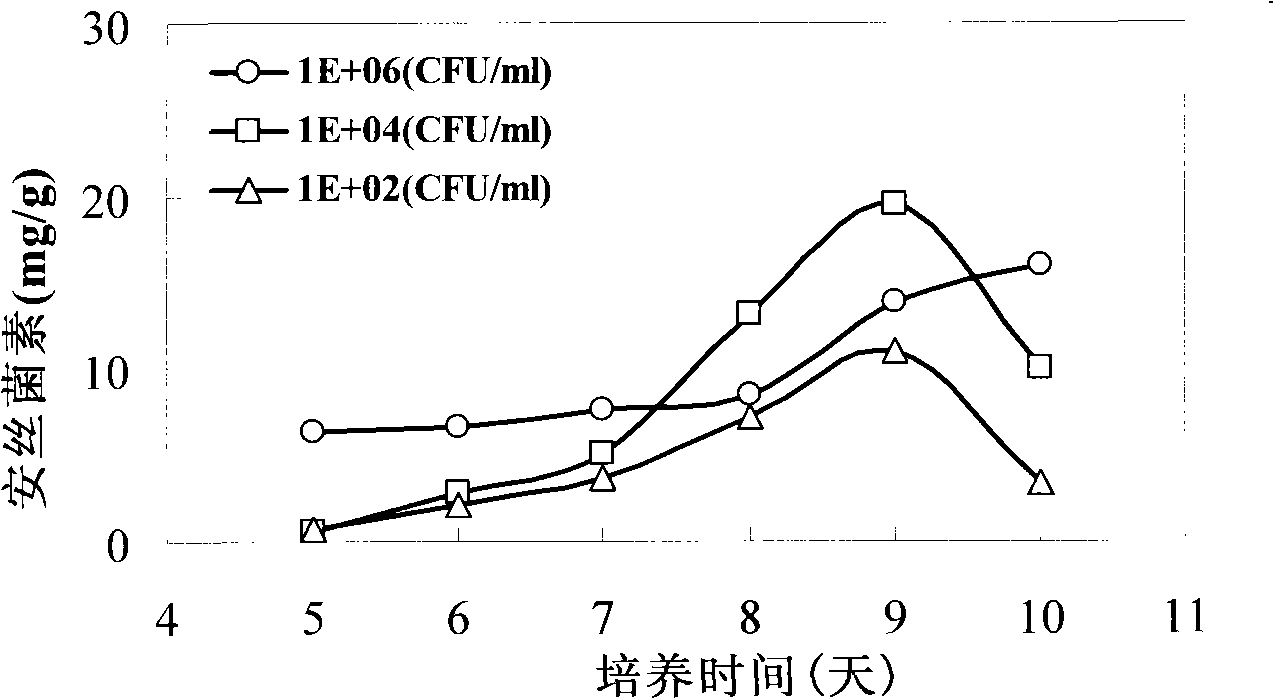

[0036] Comparison of the effect of different inoculum densities on ansamitocin in solid state fermentation using a renewable cellulose film support.

[0037] Seed and fermentation culture: The mass percentage of each component of seed culture is: yeast extract 0.4%, maltose 1%, glucose 0.4%, agar powder 1.5% and distilled water 96.7%, the diameter of the petri dish is 10cm, and the liquid volume is 15ml. 10.3% sucrose-preserved high-concentration thalline streaked YMG plates were inverted at 28°C for 2 days, and a small piece was inoculated into a 250ml shaker flask filled with 30ml of YMG medium with an inoculation shovel, at 28°C at 220 The rotation speed of rev / min was cultivated for 2 days, and after serial dilution, the 4 The concentration of CFU / ml was spread on the YMG plate covered with the regenerated cellulose film support, and cultured for 10 days at 28°C.

[0038] The method of attaching the regenerated cellulose film support is as described in Example 1.

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com