Preparation method of ionic conductor/polyoxyethylene composite solid electrolyte based on ultraviolet crosslinking

A technology of polyethylene oxide and solid electrolyte, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of large internal polarization, unfavorable battery cycle, etc., and achieve improved ion conductivity, efficient transmission path, high The effect of ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

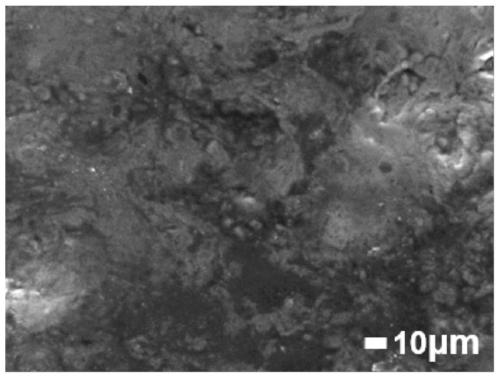

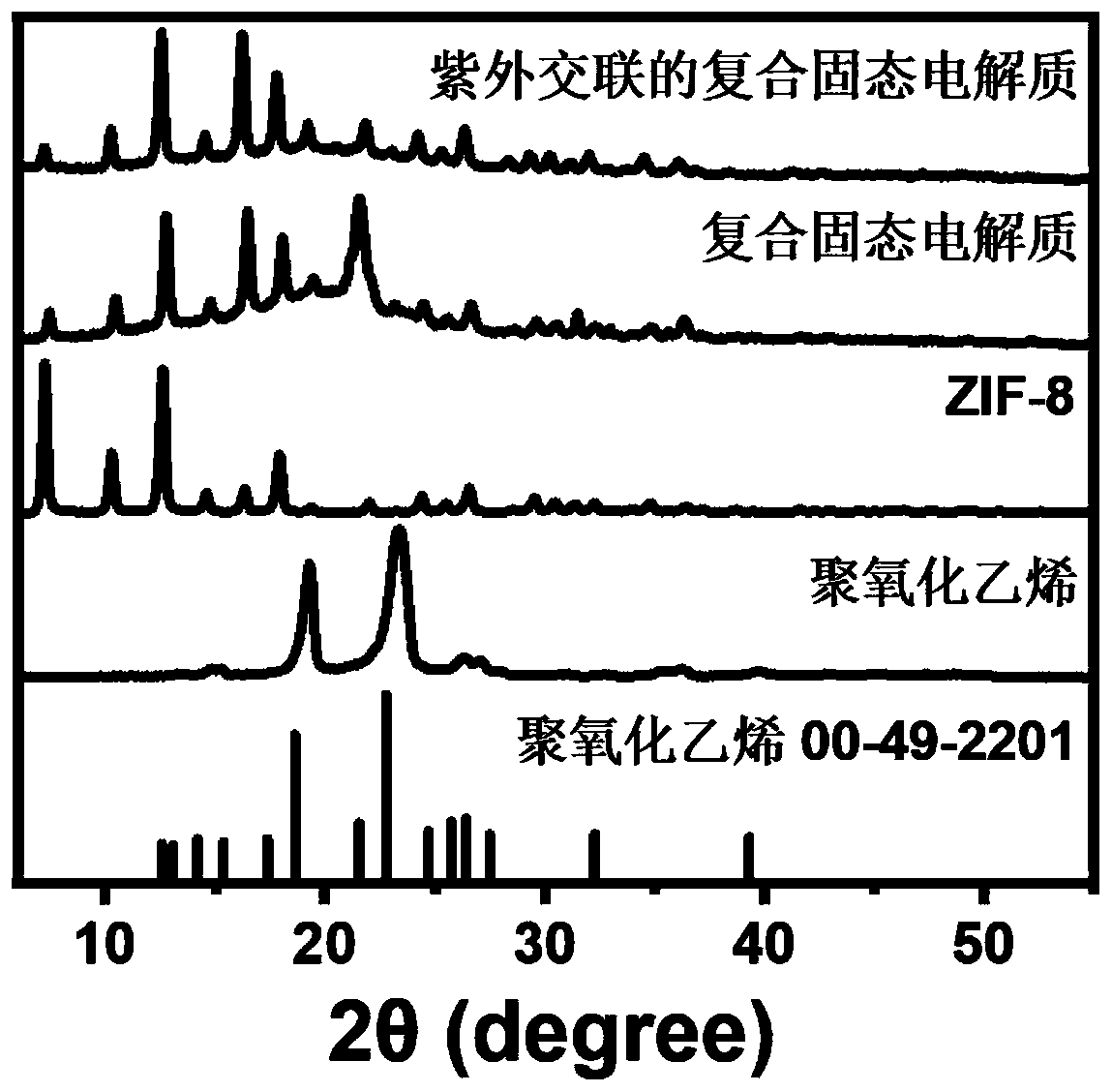

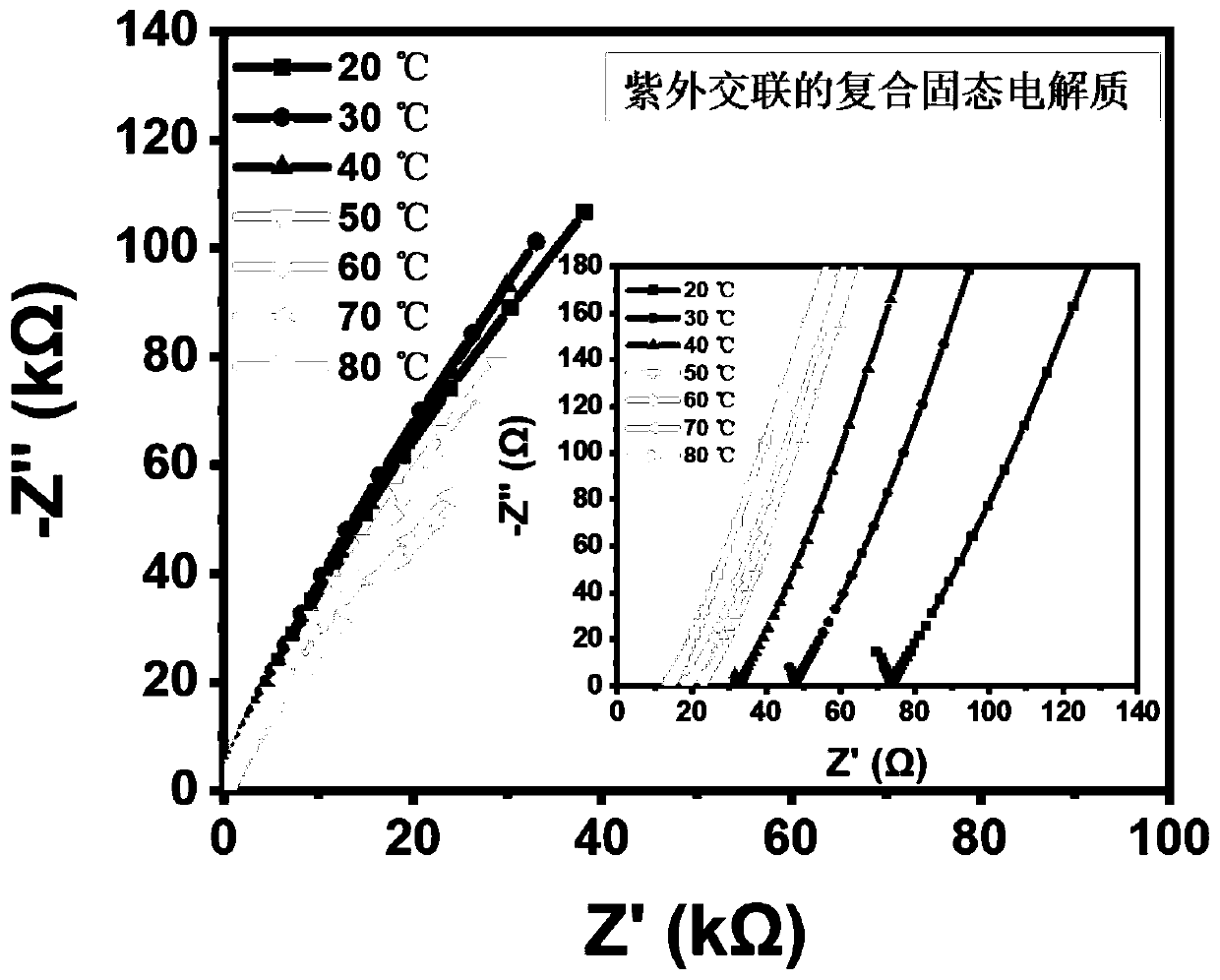

[0035] A method for preparing an ion conductor / polyoxyethylene composite solid electrolyte based on ultraviolet crosslinking comprises:

[0036] 1) Dissolve 0.3 g of zinc nitrate hexahydrate and 0.66 g of 2-methylimidazole in 11.3 g of methanol solution, and then mix and stir the two solutions for 24 hours;

[0037] 2) The mixture obtained in step 1) was centrifuged with methanol at a speed of 10,000 r / min, washed three times, and then placed in a vacuum oven at 70°C for 12 hours to prepare ZIF-8;

[0038] 3) Put the ZIF-8 material in step 2) into a vacuum oven at 120°C and place it for 12 hours to obtain activated ZIF-8;

[0039] 4) dissolving the lithium bistrifluoromethanesulfonylimide salt in an ionic liquid (EMIM-TFSI) with a mass ratio of 3:20, and stirring it magnetically for 6 hours to obtain an ionic liquid containing the lithium salt;

[0040] 5) Add the lithium salt-containing ionic liquid in step 4) into the activated ZIF-8 with a mass ratio of 1:1.5, grind it eve...

Embodiment 2

[0050] A method for preparing an ion conductor / polyoxyethylene composite solid electrolyte based on ultraviolet crosslinking comprises:

[0051] 1) Dissolve 0.3 g of cobalt nitrate hexahydrate and 0.66 g of 2-methylimidazole in 11.3 g of methanol solution, and then mix and stir the two solutions for 24 hours;

[0052] 2) The mixture obtained in step 1) was centrifuged with methanol at a speed of 10,000 r / min, washed three times, and then placed in a vacuum oven at 70°C for 12 hours to prepare ZIF-67;

[0053] 3) Put the ZIF-67 material in step 2) into a vacuum oven at 120°C and place it for 12 hours to obtain activated ZIF-67;

[0054] 4) dissolving the lithium bistrifluoromethanesulfonylimide salt in an ionic liquid (EMIM-TFSI) with a mass ratio of 3:20, and stirring it magnetically for 6 hours to obtain an ionic liquid containing the lithium salt;

[0055] 5) Add the lithium salt-containing ionic liquid in step 4) into the activated ZIF-67 with a mass ratio of 1:1.5, grind ...

Embodiment 3

[0065] A method for preparing an ion conductor / polyoxyethylene composite solid electrolyte based on ultraviolet crosslinking comprises:

[0066] 1) Dissolve 0.3 g of zinc nitrate hexahydrate and 0.66 g of 2-methylimidazole in 11.3 g of methanol solution, and then mix and stir the two solutions for 24 hours;

[0067] 2) The mixture obtained in step 1) was centrifuged with methanol at a speed of 10,000 r / min, washed three times, and then placed in a vacuum oven at 70°C for 12 hours to prepare ZIF-8;

[0068] 3) Put the ZIF-8 material in step 2) into a vacuum oven at 120°C and place it for 12 hours to obtain activated ZIF-8;

[0069] 4) dissolving the lithium bistrifluoromethanesulfonylimide salt in an ionic liquid (EMIM-TFSI) with a mass ratio of 3:10, and stirring it magnetically for 6 hours to obtain an ionic liquid containing the lithium salt;

[0070] 5) Add the lithium salt-containing ionic liquid in step 4) into the activated ZIF-8 with a mass ratio of 1:1.5, grind it eve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com