Full-automatic cup embedding feeding mechanism

A fully automatic and cup-arranging technology, applied in the field of medical devices, can solve the problems of low reliability, easy clogging of reaction cups, and failure of the mechanism to operate normally, and achieve the effect of improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

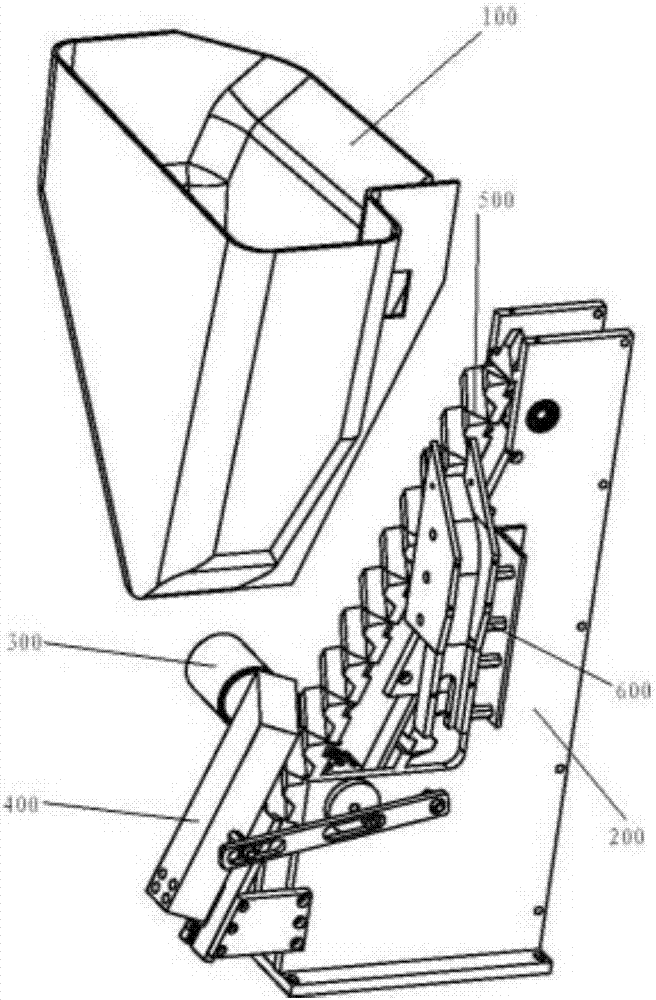

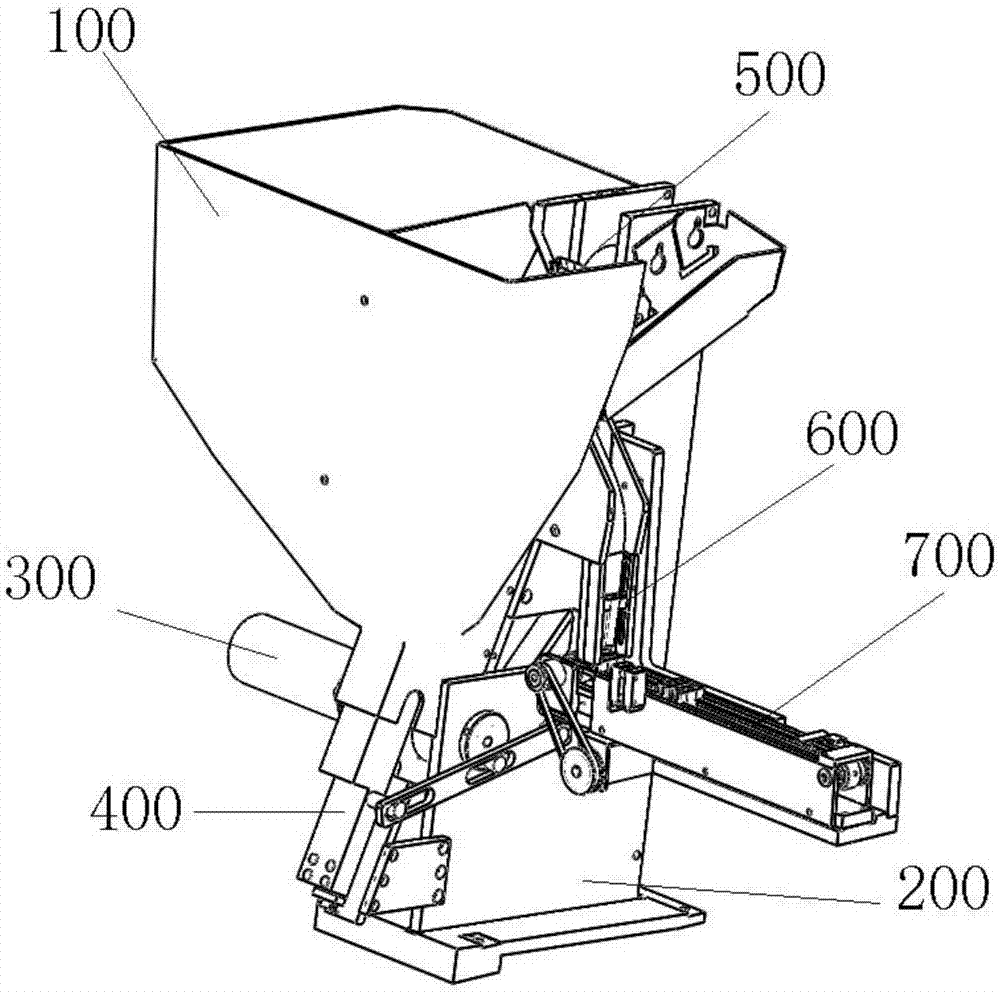

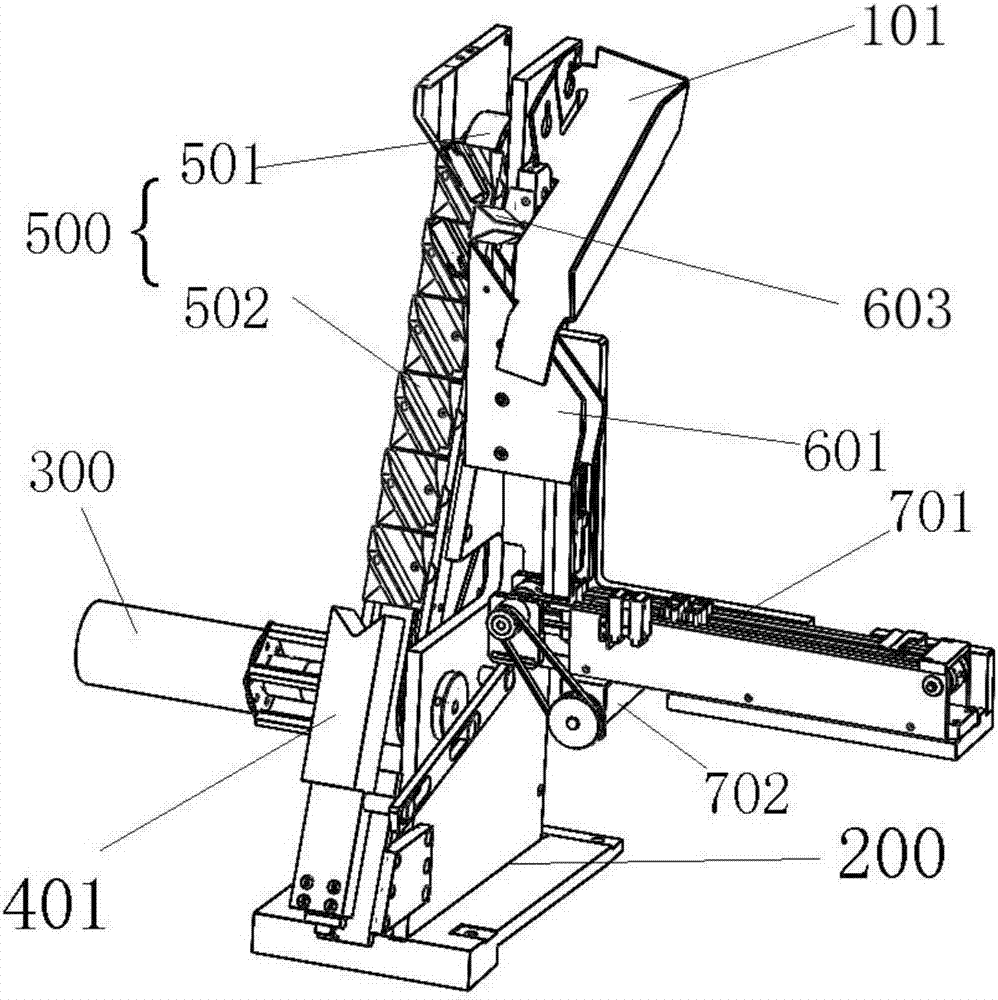

[0033] This embodiment provides a fully automatic cup feeding mechanism, such as figure 2 shown, including,

[0034] bracket assembly 200;

[0035] The discharge barrel 100 is arranged on the bracket assembly 200, has an opening at the upper end, and the cross-section gradually decreases from top to bottom along the vertical direction, and there is a partition in the middle of the discharge channel 100, which divides the discharge barrel 100 into two parts;

[0036] push cup assembly 400, such as image 3 As shown, there is a push rod 401 extending from the bottom of the discharge barrel 100 into the discharge barrel 100, which can reciprocate under the drive of the power device 300, and push the cuvette 800 when the push rod 401 reciprocates. To the receiving groove 5021 of the conveying block 502, the top of the push rod 401 is preferably a V-shaped groove;

[0037] The vertical conveying assembly 500 has an endless conveyor belt 501 and a conveying block 502 arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com