Control method for a variety of ore grinding media during ore grinding

A technology of grinding medium and control method, applied in grain processing, etc., can solve problems such as low grinding efficiency, waste of resources and energy, and large fluctuations in technological indicators in the beneficiation process, so as to improve grinding efficiency and reduce unit energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1 The present invention can be explained in more detail through the following examples, but the present invention is not limited to the following examples.

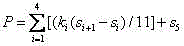

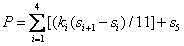

[0015] Assume that the automatic control ball adding device contains five kinds of grinding media ball storage bins, and the diameters of the stored grinding media are 50mm, 65mm, 75mm, 90mm and 100mm respectively. According to the composition content of bornite and the particle size requirements after grinding, the mass ratio of the five grinding media is required to be 1:2.5:0.9:2.2:1.2 to achieve the best grinding efficiency. Calculate the corresponding number of the five kinds of grinding media, and put it into the count corresponding to the outlet of the buffer chamber. Turn on the power supply, the control motor of the medium channel controller and the counter at the outlet of the buffer chamber start to work, each time a grinding ball medium is discharged, the counter will be decremented by one, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com