Polyamide acid copolymer and polyimide film prepared from polyamide acid copolymer

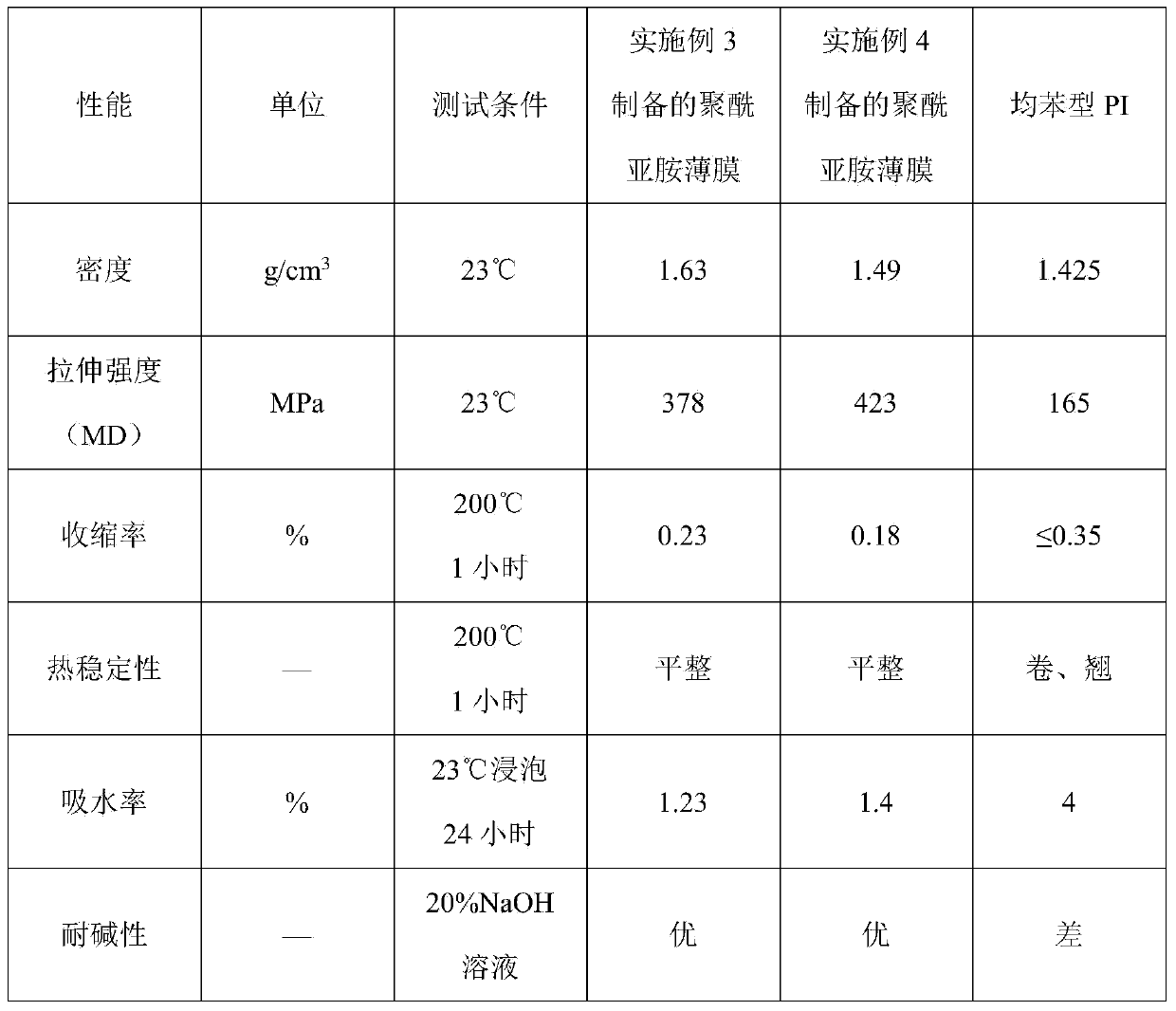

The technology of polyamic acid copolymer and polyamic acid is applied in the field of preparation of high-performance polyimide, and can solve the problems of low solubility of dianhydride and diamine, difficulty in normal reaction, high viscosity of reaction system, and the like. Achieve excellent mechanical properties and thermal stability, good stirring performance, and improve the effect of alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The reactor was filled with nitrogen, and then a total of 0.075mol of 2,2-bis[4-(4-amino-2-trifluoromethylphenoxy)benzene]hexafluoropropane and p-phenylenediamine monomer (molar ratio 1:1) was added to the reactor at one time, stirred at a constant temperature at 30°C, dissolved in N-methylpyrrolidone, and after the dissolution was complete, 1,1-bis[4-( 3,4-dicarboxyphenoxy)phenyl]cyclohexane dianhydride and 3,3'-phenylene sulfide-4,4',5,5'-biphenyltetracarboxylic dianhydride mixed monomer (total 0.076mol), the specific method is: lower the reaction temperature to 15°C, first add 0.025mol of the dianhydride mixture, then quickly lower the temperature to 5°C, then add once every hour, and add the remaining 0.051mol, then immediately move the reactor to an ultra-low temperature thermostat equipped with ethylene glycol and water cooling liquid, control the temperature at -5°C, and then react at constant temperature for 4 hours to obtain a viscous polyamic acid solution. T...

Embodiment 2

[0025]The reactor was filled with nitrogen, and then a total of 0.075 mol of 2,2-bis[4-(4-amino-2-trifluoromethylphenoxy)benzene]hexafluoropropane, p-phenylenediamine and m-phenylenediamine Mixed monomers (molar ratio 2:1:1) were added to the reactor at one time, stirred at a constant temperature at 30°C, dissolved in N,N-dimethylacetamide, and after the dissolution was complete, the molar ratio was 1 : 1,1-bis[4-(3,4-dicarboxyphenoxy)phenyl]cyclohexanedianhydride and pyromellitic dianhydride mixed monomer (0.079mol in total), the specific method is: Lower the reaction temperature to 15°C, first add 0.025mol of the dianhydride mixture, then quickly lower the temperature to 5°C, then add once every hour, add the remaining 0.054mol in three times, then immediately put the reactor Move it to an ultra-low temperature thermostat equipped with ethylene glycol and water cooling liquid, control the temperature at -10°C, and then react at a constant temperature for 8 hours to obtain a ...

Embodiment 3

[0027] The reactor was filled with nitrogen, and then a total of 0.063 mol of 2,2-bis[4-(4-amino-2-trifluoromethylphenoxy)benzene]hexafluoropropane and m-phenylenediamine mixed monomer (mol Ratio 1:1) was added to the reactor at one time, stirred at 30°C, dissolved in N,N-dimethylacetamide, after the dissolution was complete, 1,1- Bis[4-(3,4-dicarboxyphenoxy)phenyl]cyclohexane dianhydride and pyromellitic dianhydride mixed monomer (0.060mol in total), the specific method is: reduce the reaction temperature to 15°C , first add 0.020mol of the dianhydride mixture, then quickly lower the temperature to 5°C, then add once every hour, and add the remaining 0.040mol in three times, then immediately move the reactor to a place filled with ethylene glycol and In the ultra-low temperature constant temperature tank of water cooling liquid, the temperature is controlled at -15 ° C, and then the constant temperature reaction is carried out for 6 hours, and a viscous polyamic acid solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com