Outer casing material for battery and lithium secondary battery

一种外包装、电池的技术,应用在锂蓄电池、电池组零部件、非水电解质蓄电池等方向,能够解决搭载空间形状不固定、车载电源搭载空间有限等问题,达到优异绝缘性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

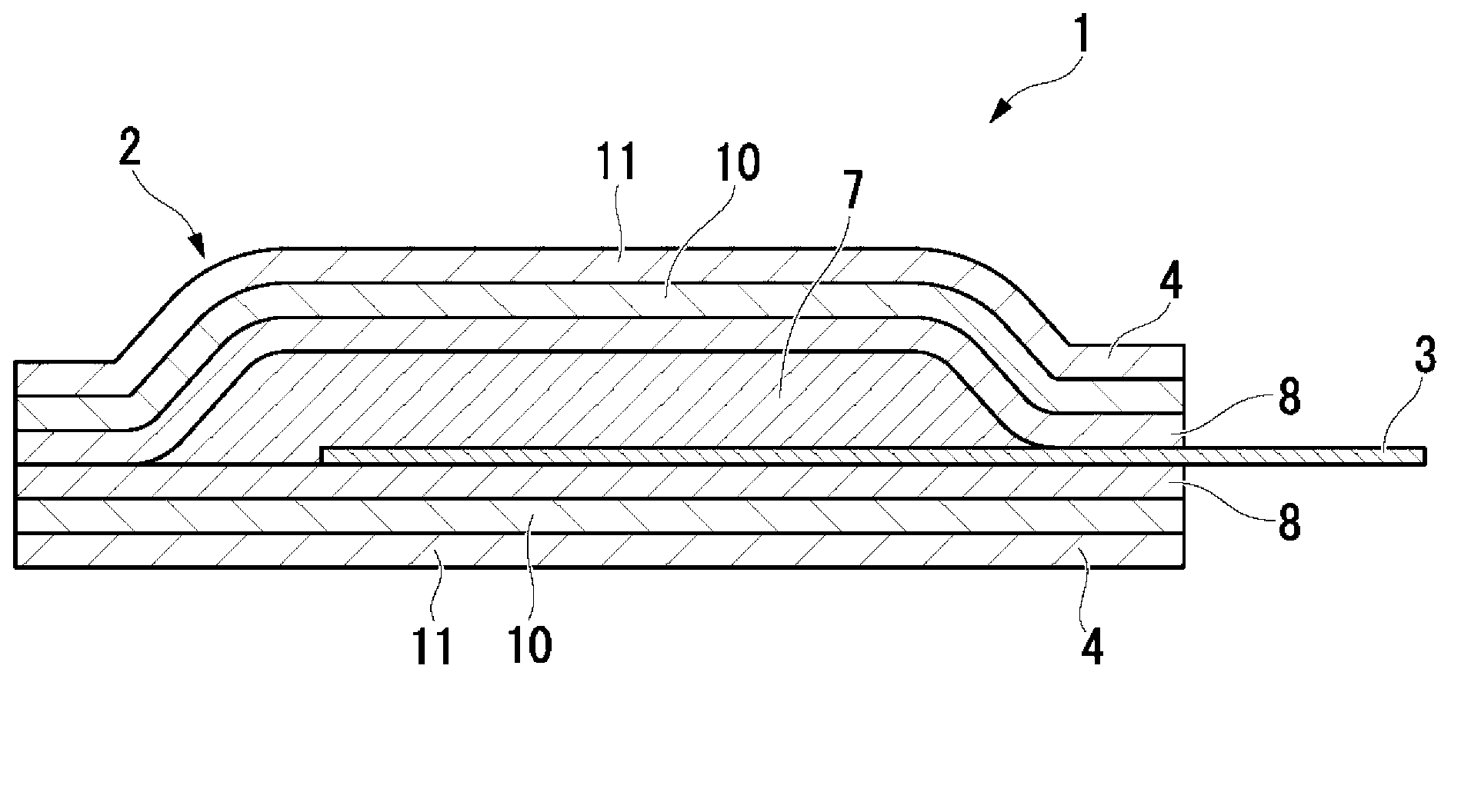

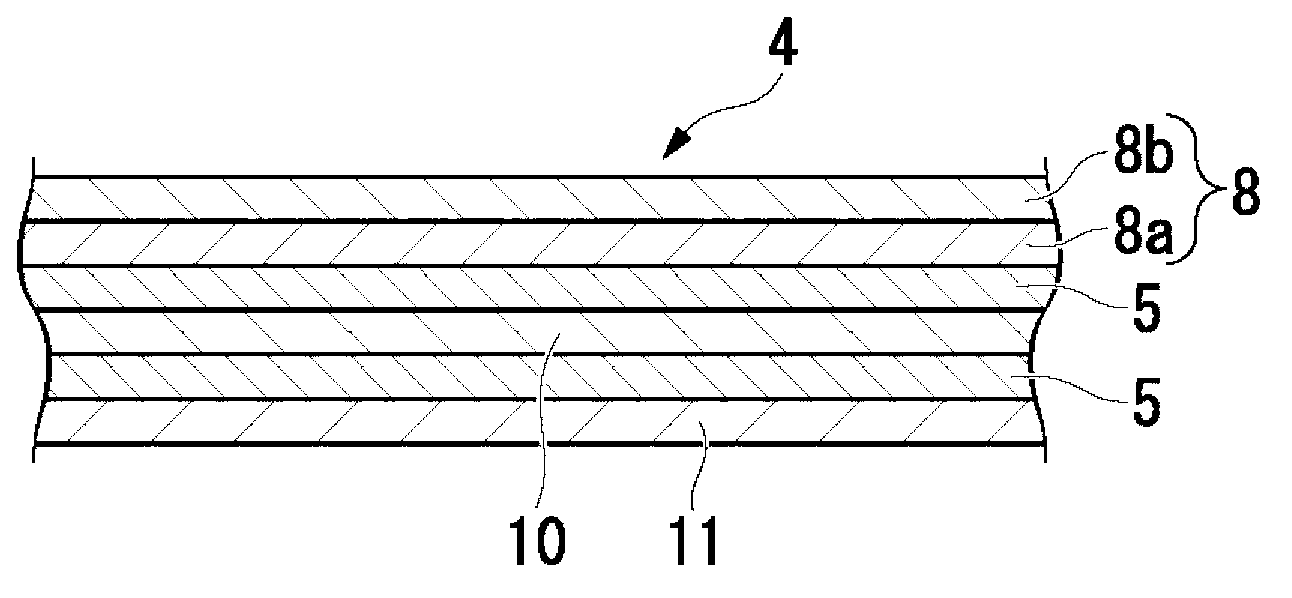

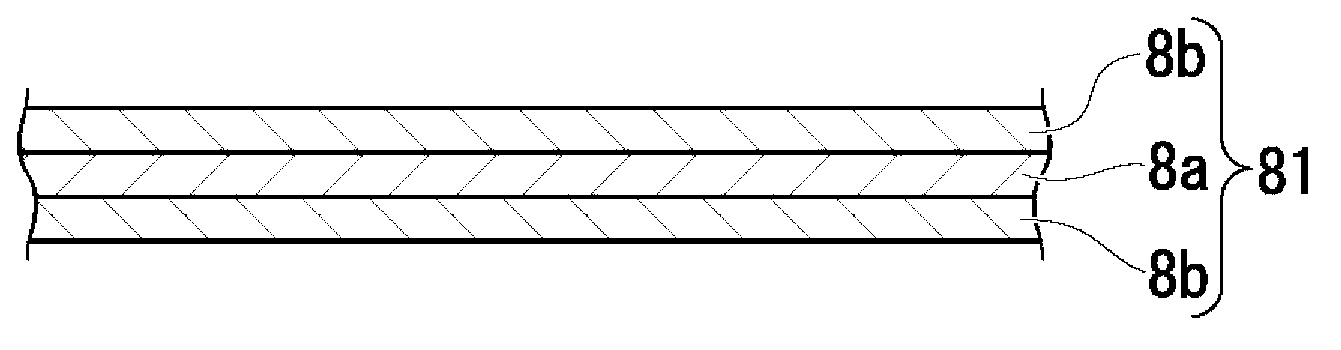

[0166] A stretched polyethylene terephthalate film with a thickness of 12 μm (manufactured by Toray Co., Ltd., general-purpose product) and a stretched polyamide film with a thickness of 15 μm (manufactured by Kohin Corporation, Ball RX) were interposed between a 3 μm two-layer film. The liquid-curable polyurethane-based adhesive layer is dry-laminated to produce an outer layer film.

[0167] Next, the obtained outer layer film and aluminum foil (JIS standard A8079H-O) with a thickness of 40 μm were dried at a speed of 80 m / min and a roll temperature of 80° C. through a 3 μm two-component curing type polyurethane adhesive layer. Dry lamination to produce a dry laminated film containing an outer layer and a metal foil layer.

[0168] Next, PP-1 (B (copolymer component) in Table 2) shown in Table 2 as a film-like resin composition (substrate layer) is a propylene-ethylene copolymer elastomer. In addition, in Table 2 The polymerized unit means a unit derived from propylene.) and...

Embodiment 2

[0173] Examples were produced in the same manner as in Example 1, except that an unstretched polypropylene film was prepared using PP-2 shown in Table 2 as a film-like resin composition (base layer) as the base layer of the inner layer. 2 The outer packing material for the battery.

Embodiment 3

[0175] On both sides of PP-1 (resin composition (substrate layer)) shown in Table 2, a propylene-ethylene copolymer (trade name: ; PM731M; manufactured by Sun Aroma Co., Ltd.) was molded by the T-die molding method to prepare an inner layer with a composition ratio (thickness ratio) of 2:6:2 (sealant layer: base material layer: sealant layer) of 80 μm unstretched polypropylene film consisting of 3 layers.

[0176] Then, the battery exterior material of Example 3 was produced in the same manner as in Example 1 except that the unstretched polypropylene film obtained in this way was used as an inner layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt Flow Rate | aaaaa | aaaaa |

| Melt Flow Rate | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com