Method for preparing aromatic hydrocarbon mixture rich in benzene, toluene and xylene (BTX) by conversion of methanol in fixed bed reactor

A fixed bed reactor, methanol conversion technology, applied in the field of coal chemical industry, can solve the problems of long process, repeated equipment construction, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

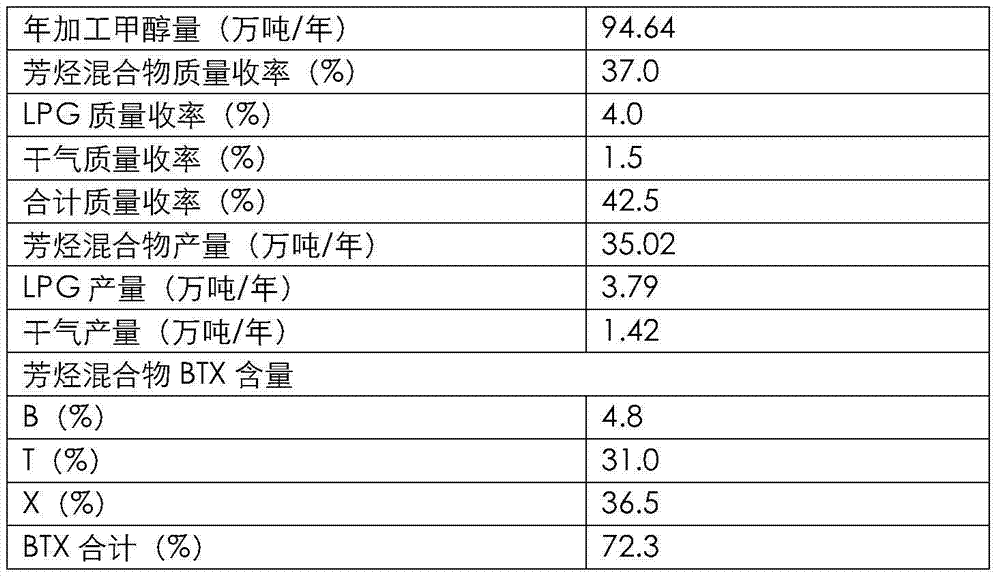

Embodiment 1

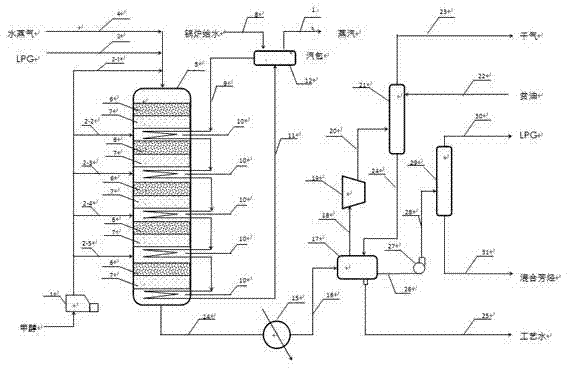

[0062] Refer to the accompanying drawings for the process flow diagram of methanol conversion in a fixed bed reactor to produce a BTX-rich aromatic hydrocarbon mixture in Example 1.

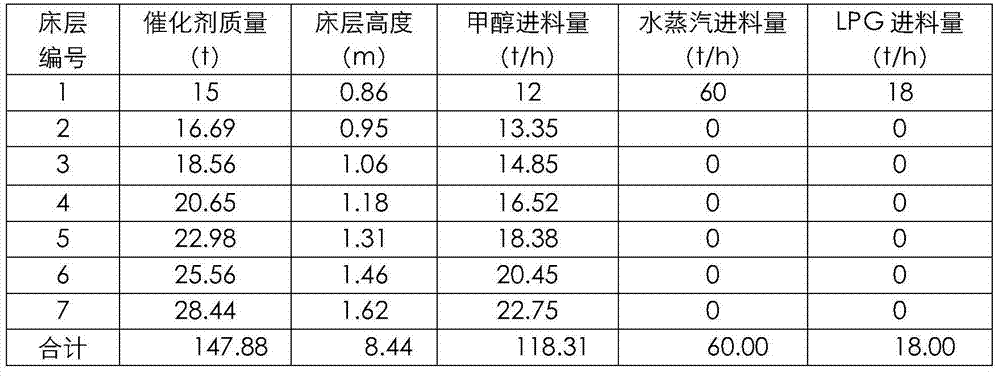

[0063] The inner diameter of the fixed bed reactor is 6.0m. The top is equipped with a reaction material inlet, the bottom is equipped with a reaction material outlet, and the side wall is equipped with 6 reaction material inlets. The catalyst is filled with 7 catalyst combination units. In the catalyst combination unit, methanol conversion to light olefin catalyst and light olefin aromatization catalyst Both are commercial catalysts, and the mass ratio of the two is 1.0. Among the materials entering the reactor from the top of the reactor, the mass ratio of water vapor and methanol is 5.0, and the mass ratio of circulating LPG and methanol is 1.2. Methanol mass space velocity is 0.8h -1 . The reaction pressure is 0.2 MPa.

[0064] Embodiment 1 The specific operation steps of the method for p...

Embodiment 2

[0082] All the conditions of Example 2 are the same as those of Example 1, but in the catalyst combination unit, the catalyst for converting methanol to low-carbon olefins and the catalyst for aromatizing low-carbon olefins are both commercial catalysts, and the mass ratio of the two is 2.0. Change the mass flow rate of water vapor at the top inlet of the reactor so that the mass ratio of water vapor to methanol vapor in the material entering the reactor from the top is 3.0. The mass flow rate of methanol vapor at each side wall inlet was changed accordingly to maintain the mass ratio of water to methanol entering each catalyst combination unit at 3.0. Methanol mass space velocity is 0.8h -1 , the temperature of each bed inlet material is controlled to be 400°C, and the reactor pressure is controlled to be 0.18MPa. Example 2 The loading parameters and material flow parameters of the catalyst combination unit in the fixed bed reactor are shown in Table 3.

[0083] Table 3. Th...

Embodiment 3

[0089] The inner diameter of the fixed bed reactor is 5.0m. The top is equipped with a reaction material inlet, the bottom is equipped with a reaction material outlet, and the side wall is equipped with 4 reaction material inlets. The catalyst is filled with 5 catalyst combination units. In the catalyst combination unit, methanol conversion to light olefin catalyst and light olefin aromatization catalyst Both are commercial catalysts, and the mass ratio of the two is 2.0. In the material entering the reactor from the top of the reactor, the mass ratio of water vapor and methanol is 5.0, and the mass ratio of circulating LPG and methanol is 1.5. Methanol mass space velocity is 1.0h -1 . The temperature of the inlet material of each bed is controlled to be 420°C, and the pressure of the reactor is controlled to be 0.25MPa. Example 3 The loading parameters and material flow parameters of the catalyst combination unit in the fixed bed reactor are shown in Table 5.

[0090] Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com