Etching agent for rapidly displaying ultrafine austenite grains and thermal erosion method thereof

A technology of austenite grains and etchant, which is applied in the fields of etchant and thermal erosion to quickly display ultra-fine austenite grains, can solve the problem of unsatisfactory erosion effect, and achieve rapid and clear display of grains highly reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

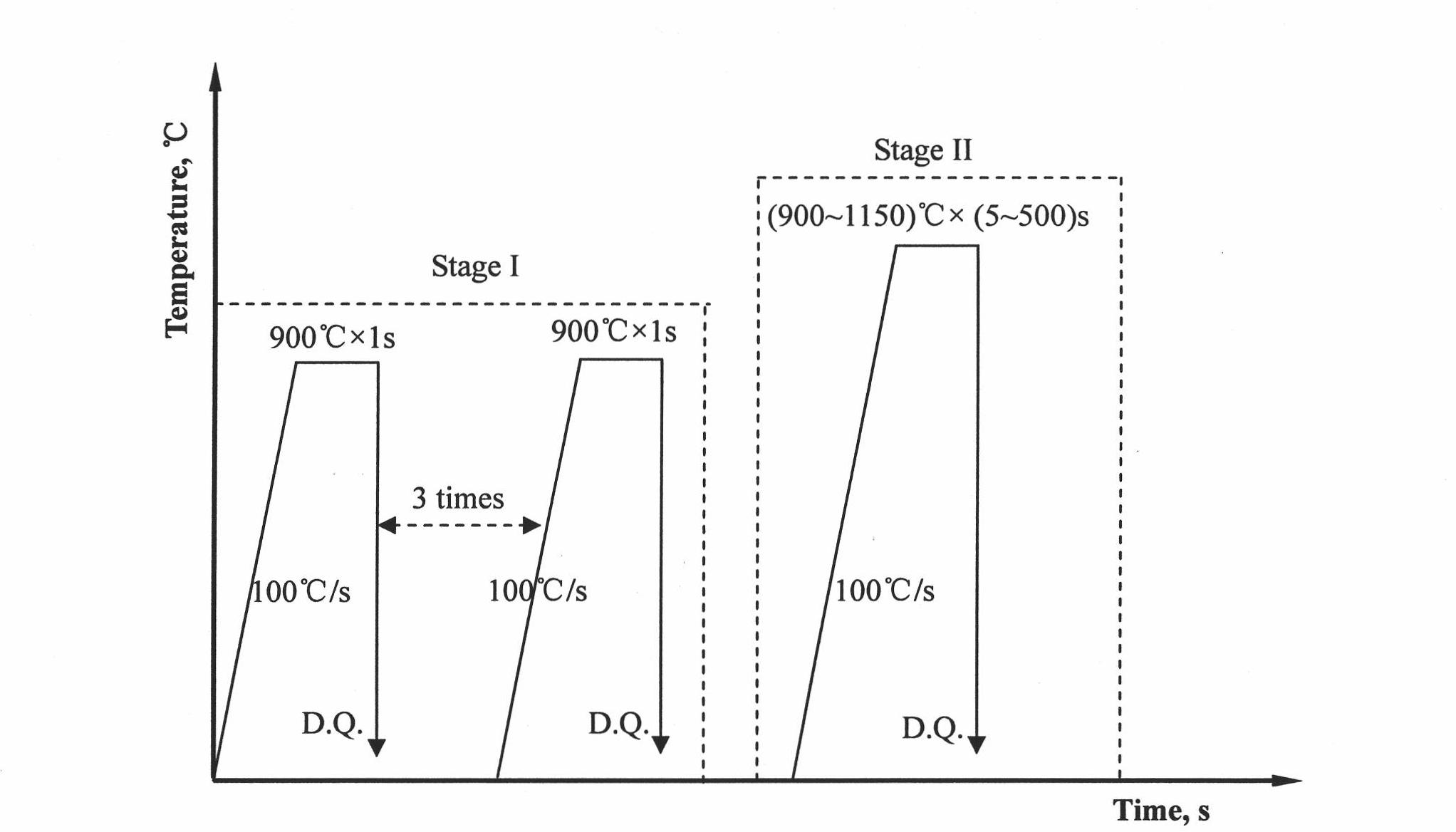

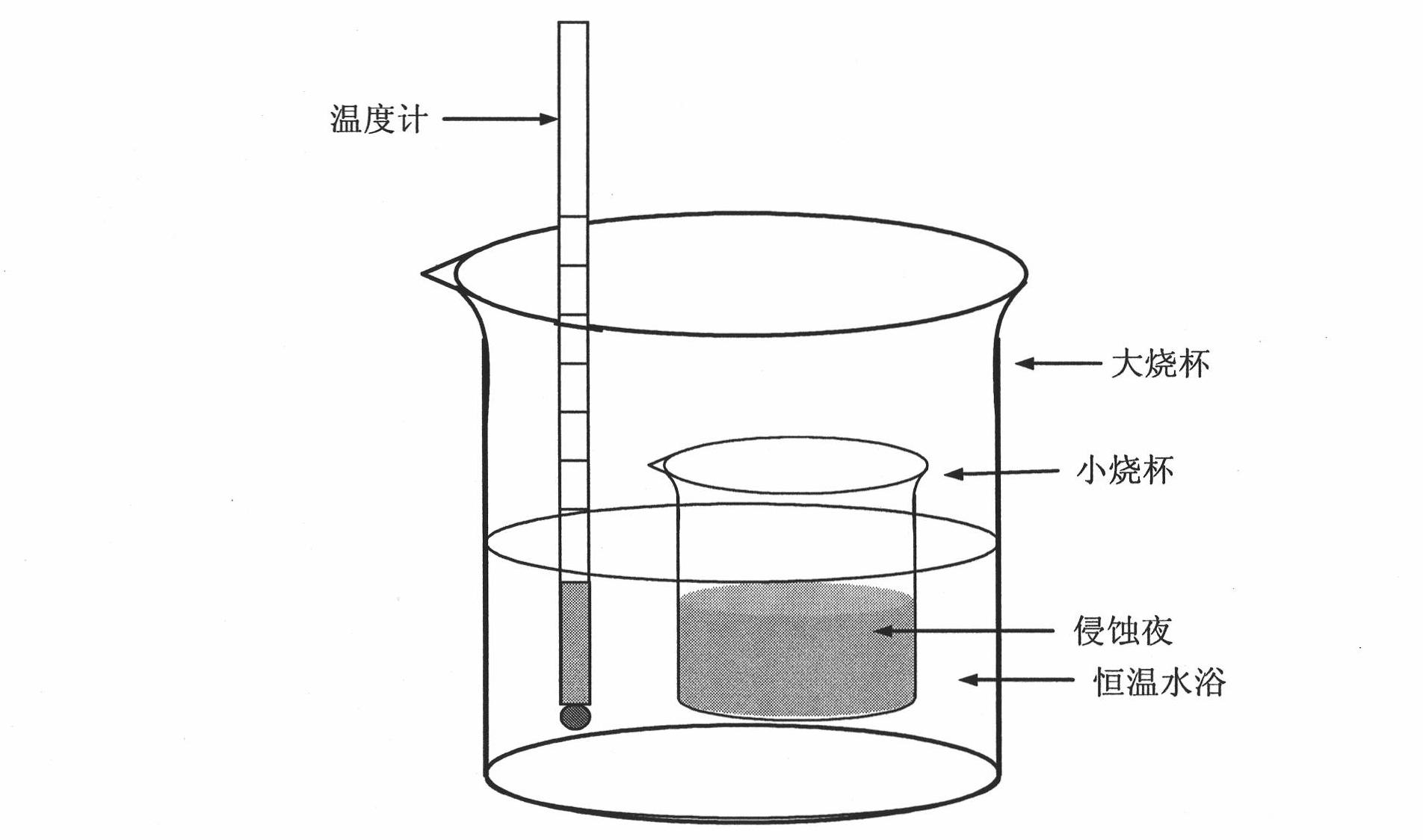

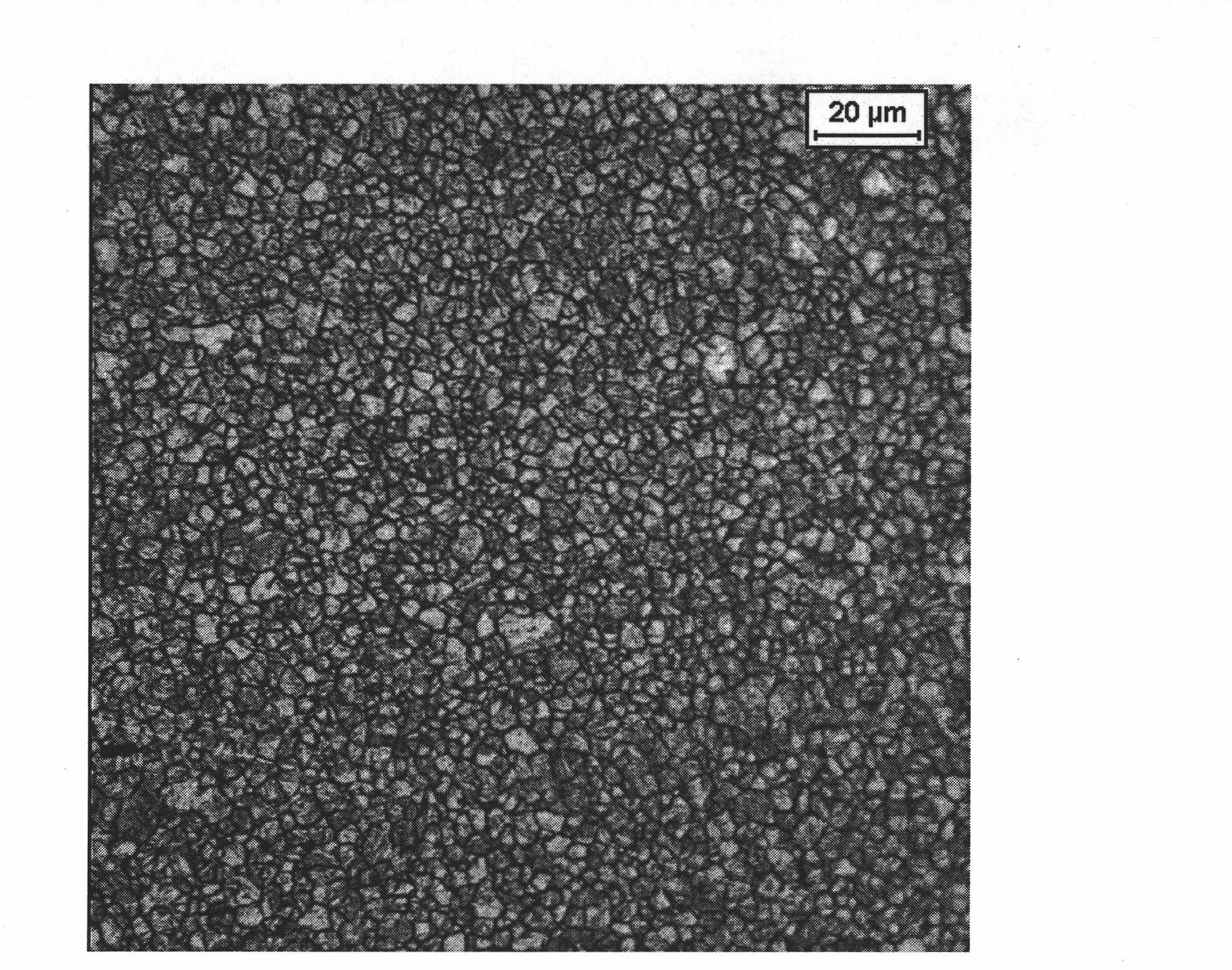

[0035] A Steel Classic figure 1 Quenching treatment in the process shown, in which the heating temperature in Stage II is 900°C and the holding time is 5s. Cut the section of the thermal simulation sample along the direction perpendicular to the compression axis near the thermocouple, after mechanical grinding and polishing, immerse the section in figure 2 60°C etchant (100ml saturated picric acid aqueous solution + 1ml CuCl 2 Solution + 0.5ml HF acid + 1ml xylene) erosion for 5s, after wiping and drying with ethanol, observe the austenite structure under an optical microscope as image 3 shown.

example 2

[0037] B steel classics figure 1 Quenching treatment in the process shown, in which the heating temperature in Stage II is 900°C and the holding time is 500s. Cut the section of the thermal simulation sample along the direction perpendicular to the compression axis near the thermocouple, after mechanical grinding and polishing, immerse the section in figure 2 60°C etchant (100ml saturated picric acid aqueous solution + 1ml CuCl 2 Solution + 0.5ml HF acid + 1ml xylene) erosion for 8s, after wiping and drying with ethanol, observe the austenite structure under an optical microscope as Figure 4 shown.

example 3

[0039] B steel classics figure 1 Quenching treatment in the process shown, in which the heating temperature in Stage II is 950°C and the holding time is 500s. Cut the section of the thermal simulation sample along the direction perpendicular to the compression axis near the thermocouple, after mechanical grinding and polishing, immerse the section in figure 2 60°C etchant (150ml saturated picric acid aqueous solution + 1.5ml CuCl 2 Solution + 1ml HF acid + 1ml xylene) erosion for 10s, after wiping and drying with ethanol, observe the austenite structure under an optical microscope as Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com