Foundry self-hardening sand recycling system process

A regeneration system and no-bake sand technology, applied in manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of waste of resources for one-time use of molding sand, environmental pollution, high production costs, etc., and achieve production cost saving and operation control The effect of convenience and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

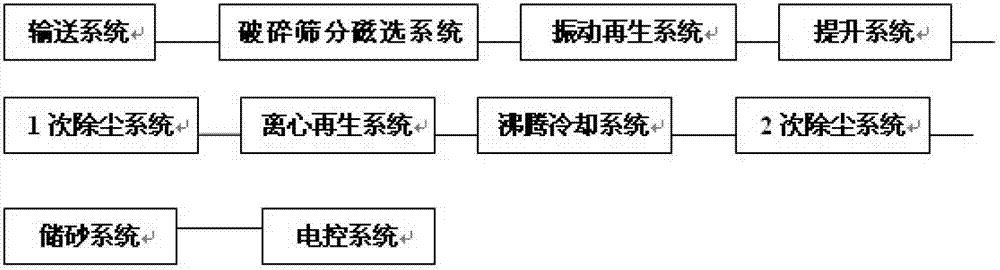

[0017] Refer to the attached figure, the recovery and recycling system process of no-bake sand for foundry, the process includes, conveying system, crushing and screening magnetic separation system, vibration regeneration system, lifting system, primary dust removal system, centrifugal regeneration system, boiling cooling system, 2 Secondary dust removal system, sand storage system, dust removal system and electric control system.

[0018] The conveying system includes a belt conveyor, a magnetic separation head wheel, the belt conveyor transports sand, and a magnetic separation head wheel is set above the belt conveyor to remove iron-containing substances, and then enters the recycling machine.

[0019] The crushing and screening magnetic separation system includes a centrifugal regenerator, a crusher, a bucket elevator, a vibrating linear screen and a vibrating feeder. The old sand in the sand bucket is evenly fed to the crusher through the vibrating feeder. Crushing, primar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com