Self-hardening resin insulation board or building block and manufacturing method thereof

A manufacturing method and technology of thermal insulation boards, which are applied in the directions of thermal insulation, insulation improvement, building components, etc., can solve the problem of not yet retrieved core thermal insulation boards or blocks, and achieve the advantages of improving anti-breakage performance, improving life, and improving construction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

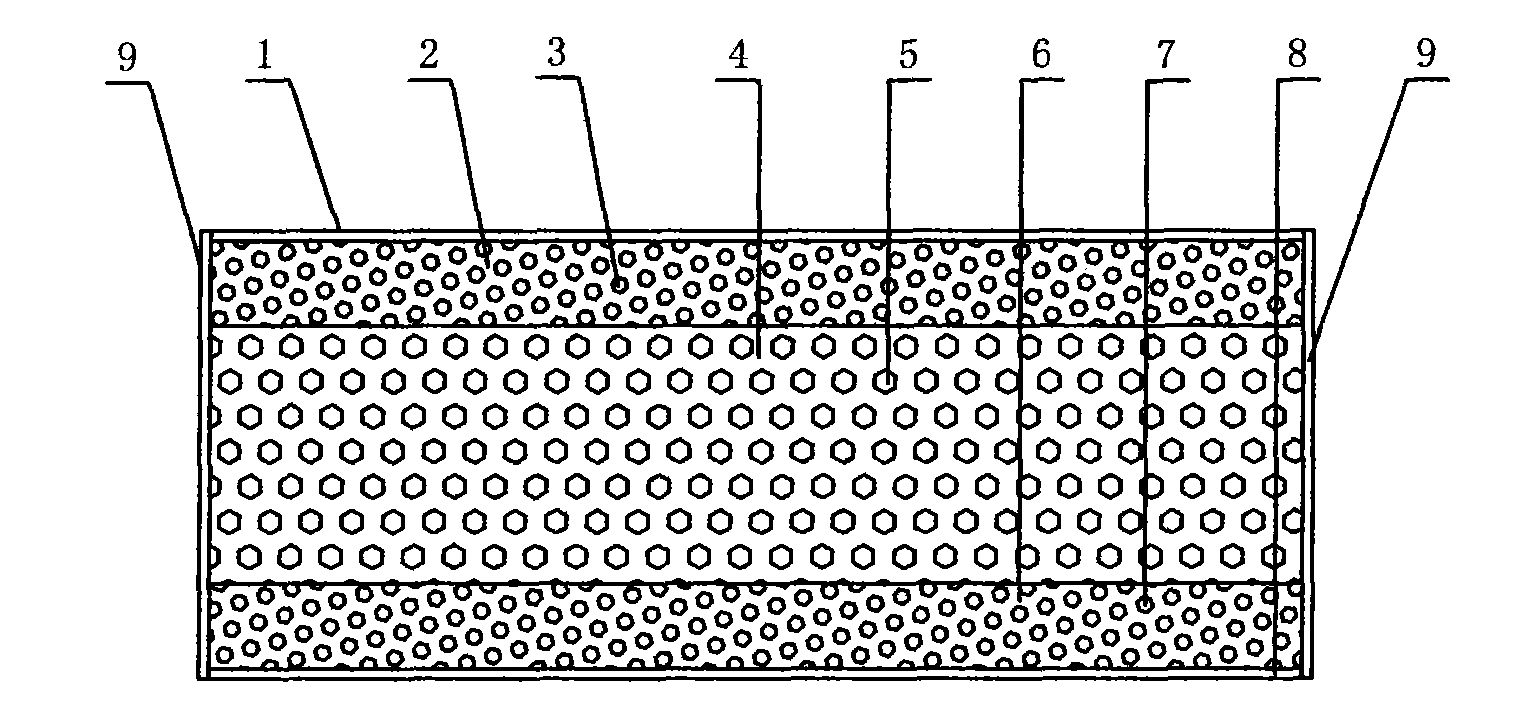

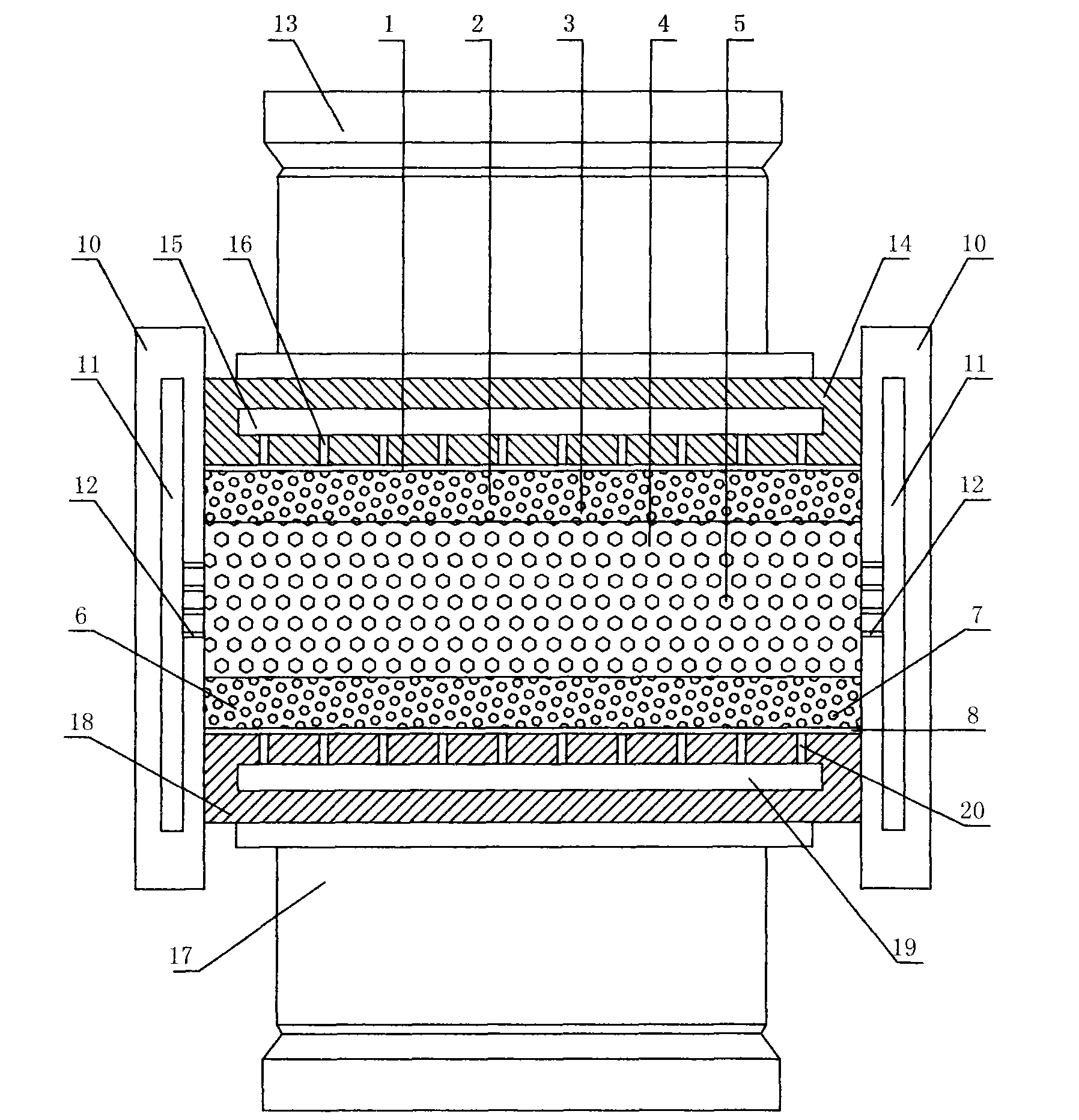

[0035] Vacuum and pressure forming self-hardening resin expanded perlite insulation board end structure diagram is as follows figure 1 as shown, figure 2 yes figure 1 Vacuum and pressure forming no-hardening resin expanded perlite insulation board pressure-manufactured cross-sectional structure diagram, in which: 1 is the surface layer release paper, 2 is the surface layer of furan resin adhesive, 3 is the surface layer of hollow glass beads, 4 is the core layer Furan resin binder, 5 is the core layer expanded perlite, 6 is the bottom furan resin binder, 7 is the bottom hollow glass microsphere, 8 is the bottom anti-sticking paper, 9 is the closed self-hardening resin film, 10 is the forming mold, 11 is the vacuum cavity of the forming mold, 12 is the vacuum suction hole of the forming mold, 13 is the upper compression cylinder, 14 is the upper flat mold, 15 is the vacuum cavity of the upper flat mold, 16 is the vacuum suction hole of the upper flat mold, 17 is the lower com...

Embodiment 2

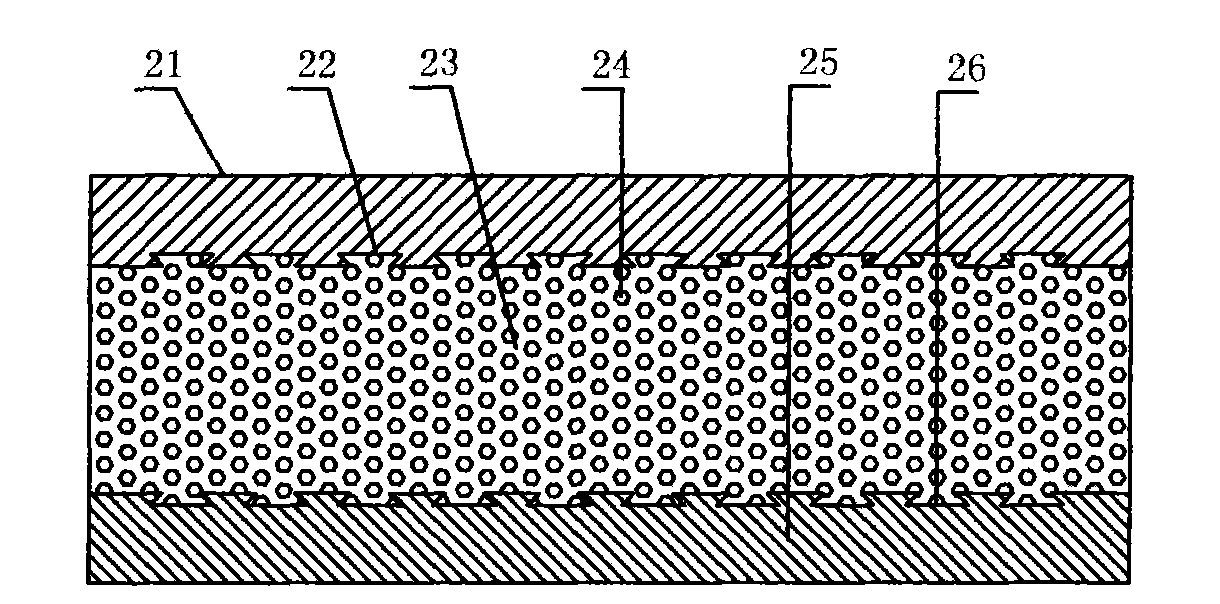

[0039] The structure diagram of the end surface of pressure-formed self-hardening resin expanded perlite wood-plastic insulation board is as follows image 3 as shown, Figure 4 yes image 3 Pressure-molded self-hardening resin expanded perlite wood-plastic insulation board pressure-manufactured cross-sectional structure diagram, in which: 21 is the wood-plastic panel, 22 is the concave-convex groove of the wood-plastic panel, 23 is the furan resin adhesive for the core layer, 24 is the expanded perlite core layer, 25 is the wood-plastic bottom plate, 26 is the concave-convex groove of the wood-plastic bottom plate, 27 is the forming mold, 28 is the upper compression cylinder, 29 is the upper flat mold, 30 is the vacuum cavity of the upper flat mold, 31 is the vacuum suction hole of the upper flat mold, and 32 is Lower compression cylinder, 33 is lower flat mold, 34 is lower flat mold vacuum chamber, and 35 is lower flat mold vacuum suction hole.

[0040] When manufacturing ...

Embodiment 3

[0043] Vacuum and pressure forming wrapped organic resin film self-hardening resin expanded vermiculite insulation board end structure diagram Figure 5 as shown, Figure 6 yes Figure 5 Vacuum and pressure forming wrapping organic resin film self-hardening resin expanded vermiculite insulation board manufacturing sectional structure diagram, in which: 36 is organic resin film, 37 is furan resin binder for core layer, 38 is core layer vermiculite, 39 is organic resin film Vacuum suction hole, 40 is a vacuum suction head, 41 is a molding die, 42 is an upper compression cylinder, 43 is an upper flat mold, 44 is a lower compression cylinder, and 45 is a lower flat mold.

[0044] When manufacturing the self-hardening resin expanded vermiculite thermal insulation board wrapped with organic resin film, the core layer expanded vermiculite 38 mixed with the core layer furan resin adhesive 37 and curing agent is poured into the organic resin film 36 first, and the perfused core layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com