Anti-deformation method for casting vane of ultra-large mixed flow type water turbine

A water turbine and mixed-flow technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of excessive processing of blades, shortening the production cycle, fat head and big ears, etc., to eliminate deformation, reduce deformation, and ensure Rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

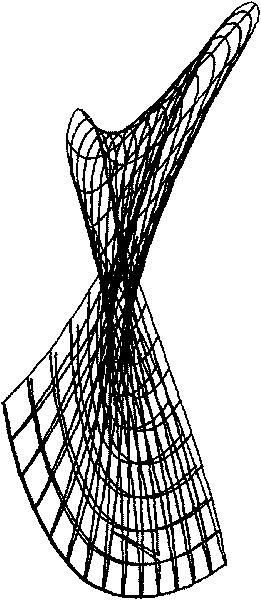

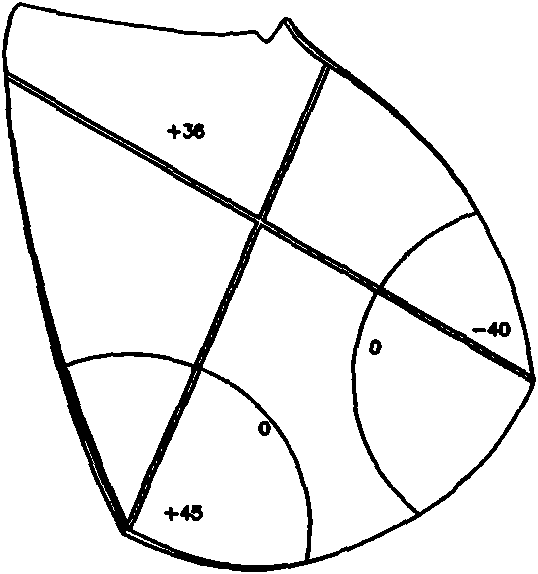

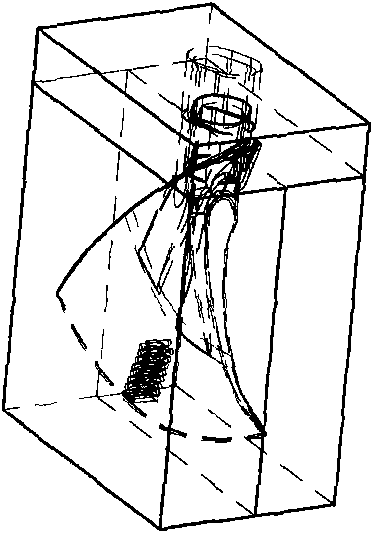

[0024] A casting method for anti-deformation of blades of a super-large Francis water turbine, including mold making, molding, box closing, pouring, sand shakeout, cleaning and heat treatment, and is characterized in that: the above-mentioned mold making is figure 1 The steel-wood mesh frame shown is the aggregate, which is filled with resin and supported according to the molding line, such as image 3 Shown: Three boxes of T-shaped boxes are used, real sample molding, flat casting and vertical pouring, combined sand box, resin self-hardening sand, chromite sand is used for surface sand, steel skeleton is placed in the molding sand, heat treatment adopts such as Figure 4 The vertical furnace loading method shown uses U-shaped support tooling. The riser is cut to reserve a flat riser neck, which is directed downwards to support the blades. There are clamps on both sides of the riser neck to ensure the vertical direction of the blades.

[0025] Make a tire plate that completely...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com