Composite scale inhibitor

A composite scale inhibitor and polymer technology, which is applied in the fields of scale removal and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of carrying out, the preparation method is simple, and prolonging the service cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

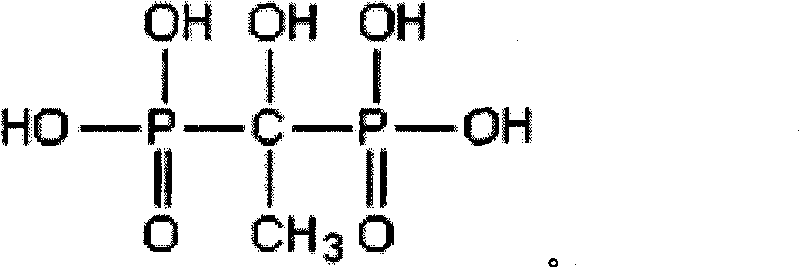

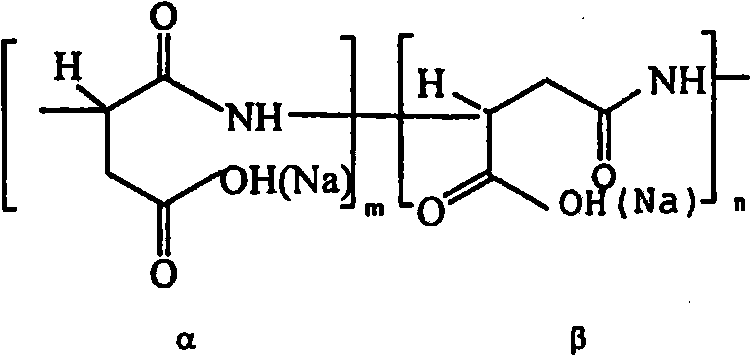

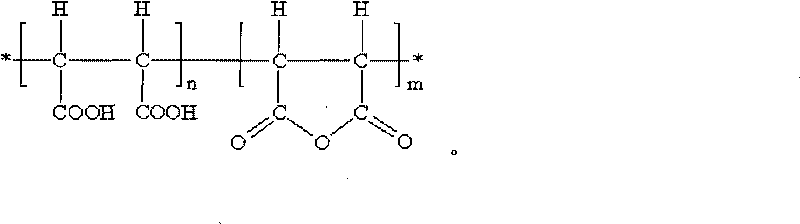

Method used

Image

Examples

Embodiment 1

[0028] Prepare 100kg of cooling water composite scale inhibitor, preparation process: add HEDP 2.381kg, polymaleic acid dry 2.381kg, polyaspartic acid 11.905kg, polyacrylic acid terpolymer 11.905kg, polyacrylic acid tetrapolymer 11.905 kg, the rest is water, with a solid content of 39.62%.

[0029] For scale inhibition of industrial circulating cooling water systems, the indicators of cooling water are as follows:

[0030] Concentration ratio ≥ 6, total alkali 987mg / L, total hardness 978mg / L calculated as calcium carbonate, pH=7.78.

[0031] The amount of cooling water with a solid content of 70mg / L is added, and the scale inhibition performance is tested with reference to "Cooling Water Analysis and Experimental Methods" compiled by the Production Department and Development Department of China Petrochemical Corporation (published by the Information Center of Anqing Petrochemical Factory in 1993 ) in the "calcium carbonate deposition method" for static scale inhibition experi...

Embodiment 2

[0033] Prepare 100kg of cooling water composite scale inhibitor, preparation process: add HEDP 0.293kg, dry polymaleic acid 5.865kg, polyaspartic acid 17.595kg, polyacrylic acid tetrapolymer 17.595kg, the rest is water, solid content 41.35 %.

[0034] For scale inhibition of industrial circulating cooling water systems, the indicators of cooling water are as follows:

[0035] Concentration ratio ≥ 6, total alkali 987mg / L, total hardness 978mg / L calculated as calcium carbonate, pH=7.78.

[0036] The amount of cooling water with a solid content of 70mg / L is added, and the scale inhibition performance is tested with reference to "Cooling Water Analysis and Experimental Methods" compiled by the Production Department and Development Department of China Petrochemical Corporation (published by the Information Center of Anqing Petrochemical Factory in 1993 ) in the "calcium carbonate deposition method" to carry out the static scale inhibition experiment, the experimental results are ...

Embodiment 3

[0038] Prepare 100kg of cooling water composite scale inhibitor, preparation process: add HEDP 2.614kg, polymaleic acid dry 2.614kg, polyaspartic acid 6.536kg, polyacrylic acid terpolymer 16.340kg, polyacrylic acid tetrapolymer 6.536 kg, the rest is water, with a solid content of 34.64%.

[0039] For scale inhibition of industrial circulating cooling water systems, the indicators of cooling water are as follows:

[0040] Concentration ratio ≥ 6, total alkali 987mg / L, total hardness 978mg / L calculated as calcium carbonate, pH=7.82.

[0041] Add in the amount of cooling water with a solid content of 60mg / L, and the test of scale inhibition performance refers to "Cooling Water Analysis and Experimental Methods" compiled by the Production Department and Development Department of China Petroleum and Chemical Corporation (published by Anqing Petrochemical General Plant Information Center in 1993 ) in the "calcium carbonate deposition method" to carry out static scale inhibition exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com