Hot and cold composite precision forging forming method of great-modulus high-thickness straight-tooth cylindrical gear

A spur gear, cold compound technology, applied in the field of metal plastic processing, can solve the problems of shortening the life of the cold finishing die, the stress concentration of the toothed die, affecting the performance of the final part, etc., so as to achieve less machining time and reduce stress. Concentration phenomenon, high material utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Embodiments of the present invention are further described below:

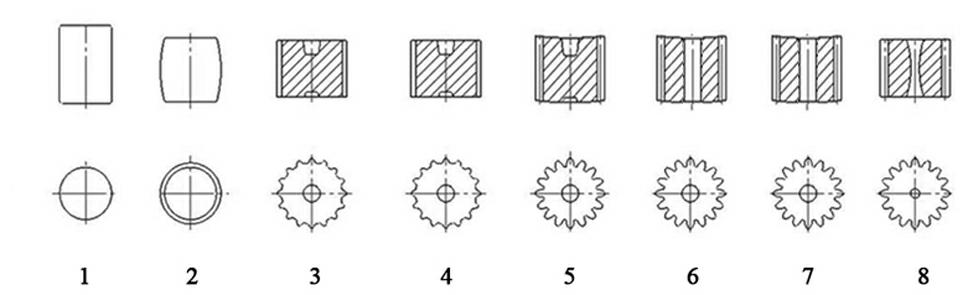

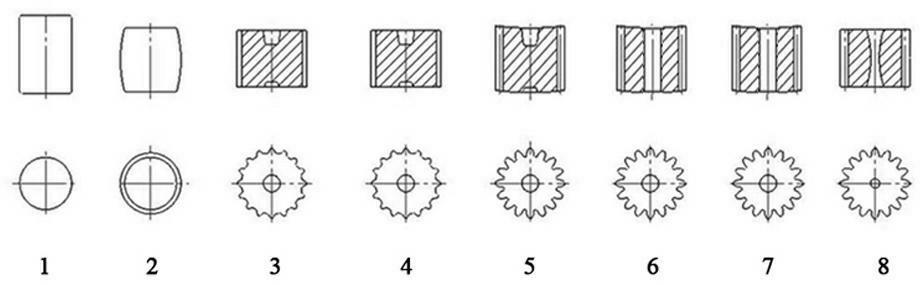

[0008] The steps of the cold extrusion compound forming method for large modulus and high thickness spur gears are: (1) blanking → (2) upsetting after heating → (3) hot die forging → (4) annealing intermediate treatment → (5) Cold forward extrusion → (6) machining center hole → (7) annealing intermediate treatment → (8) cold finishing.

[0009] (1) Cutting: The round steel bar is cut into a billet of a certain length, and after passing the electronic weighing inspection, a qualified original billet is obtained.

[0010] (2) Upsetting after heating: The billet is heated to the initial forging temperature by heating equipment, and the upsetting station of the heated billet on the press is upset into a drum shape.

[0011] (3) Hot die forging: Hot die forging the upsetting blank into a tooth-shaped forging blank. The tooth shape of the forging blank is the upper half of the tooth shape approximate to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com