Water turbine

A water turbine and outlet technology, which is applied in the fields of hydropower, mechanical equipment, engine components, etc., can solve the problems of reduced unit output, inability to remove, and blocked nozzle debris, so as to increase annual power generation, avoid power generation losses, and improve the overall well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

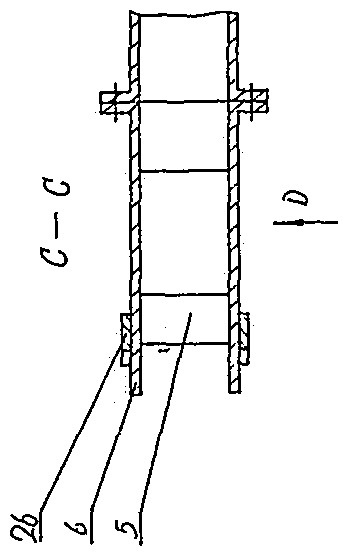

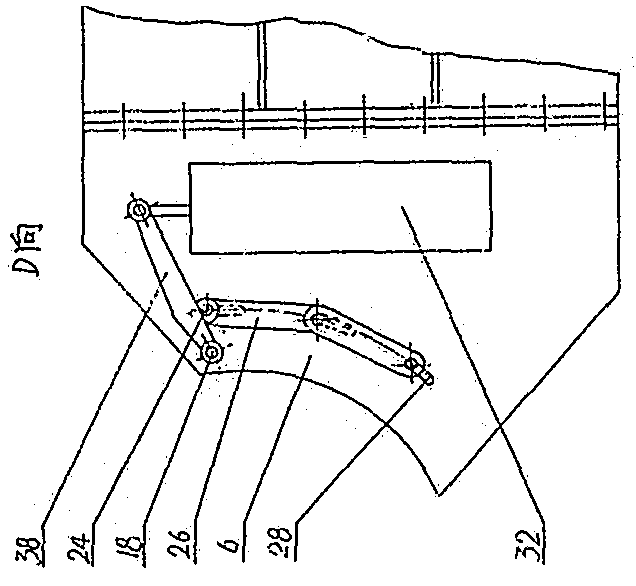

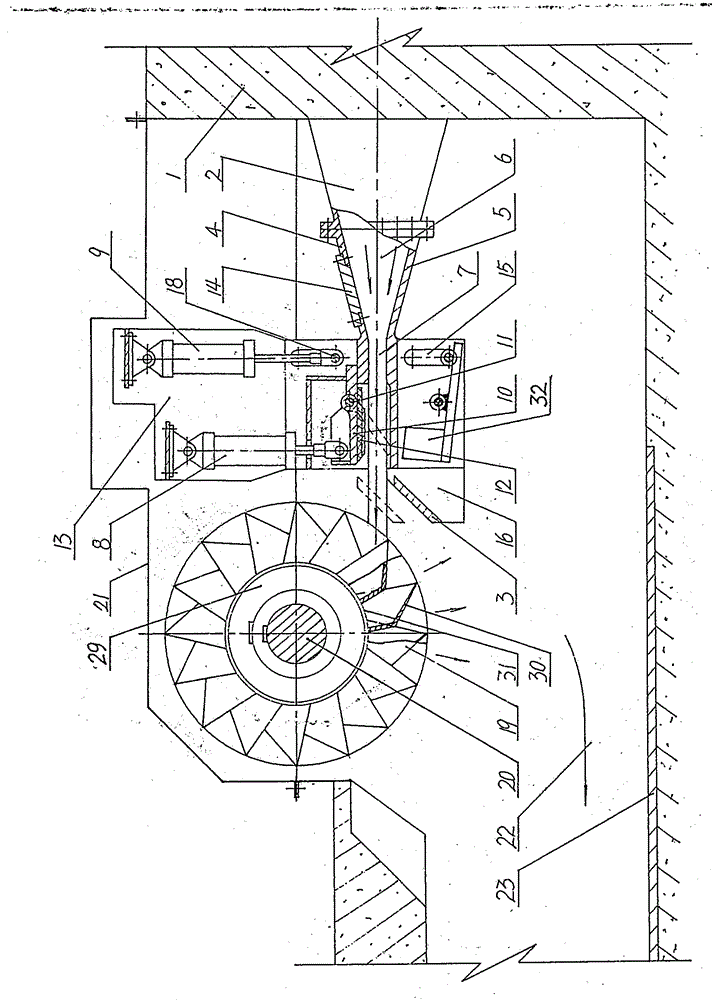

[0036] figure 1 A first embodiment of the invention is shown.

[0037]As shown in the figure: the water outlet of the pressure diversion chamber 1 is connected with an outlet 2 with a rectangular cross-sectional shape, and the water outlet of the outlet 2 is fixedly connected with a top plate 4, a bottom plate 5 and side plates 6 on both sides. Constituted outlet 7. There is a rotary valve 10 at the water outlet end of the top plate 4 through a door shaft 11 hinged device, and a flat rubber seal 12 covering its surrounding edges is provided under the rotary valve 10 and the door shaft 11 through a pressure plate device, and hinged at the top of the water outlet end of the rotary valve 10 A servomotor 8 is connected, and the other end of the servomotor 8 is hinged on the support at the top of its support plate 13, and the pressure infusion pipe of the servomotor 8 is connected with the governor hydraulic device. The middle part of the top plate 4 is provided with an inspectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com