Simple gas-liquid separation apparatus in rotating development vacuum line

A gas-liquid separation device, vacuum pipeline technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as mixing developer, and achieve the effects of reducing corrosion problems, simple structure, and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

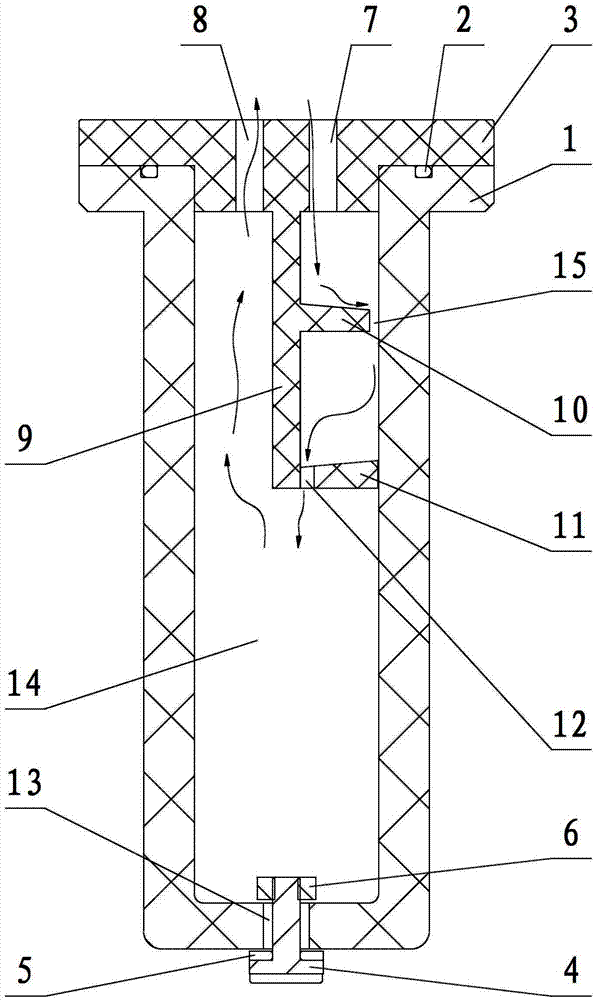

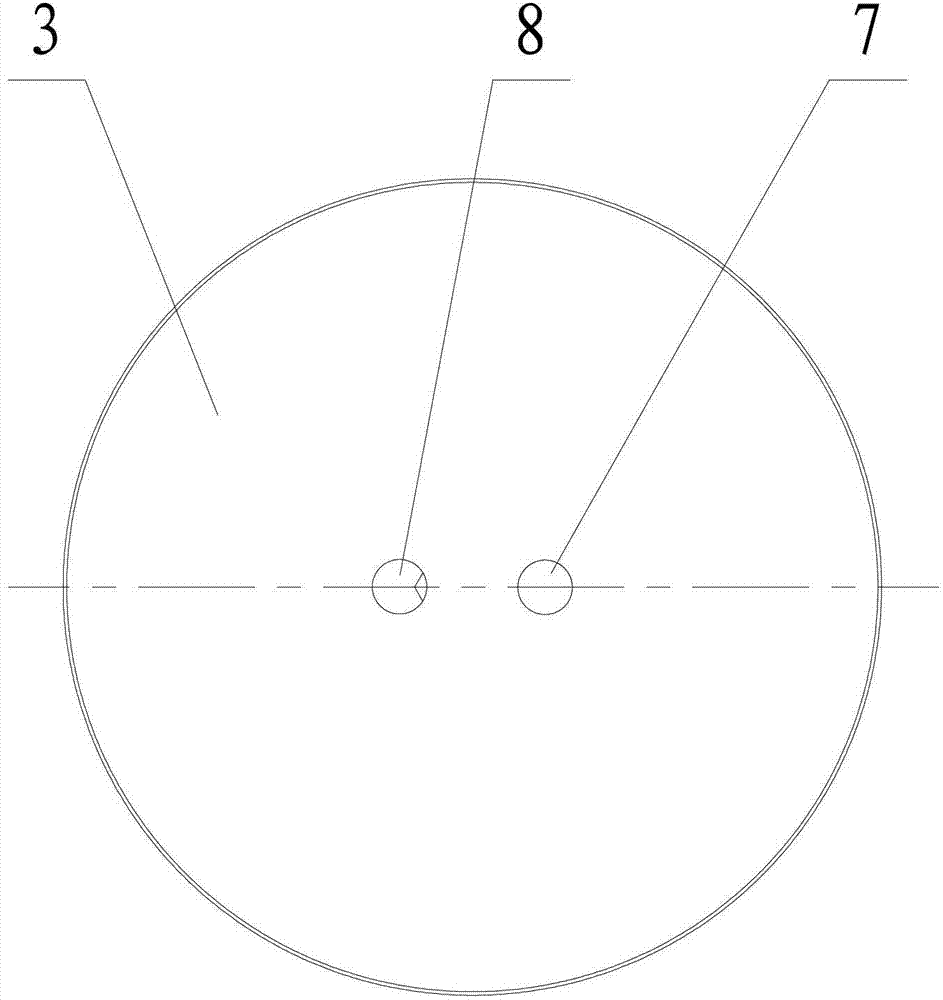

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] The present invention is used to remove the developing solution entering the vacuum pipeline during rotary development, such as figure 1 , figure 2 As shown, it includes a cylinder body 1, a cylinder cover 3 and a movable plug 4, wherein the cylinder body 1 is an internal hollow structure with a cavity 14 in the middle, one end of the cylinder body 1 is sealed and connected with the cylinder cover 3 through a sealing ring 2, and the other end is opened. There is a drain port 13.

[0018] The movable plug 4 is inserted in the liquid discharge port 13 , and the switch of the liquid discharge port 13 is controlled by the movable plug 4 reciprocating along the axial direction of the cylinder body 1 . The axial section of the movable plug 4 is an inverted "T" shape, and one end (the end with a smaller diameter) of the movable plug 4 is inserted into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com