Patents

Literature

58 results about "Headed large" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

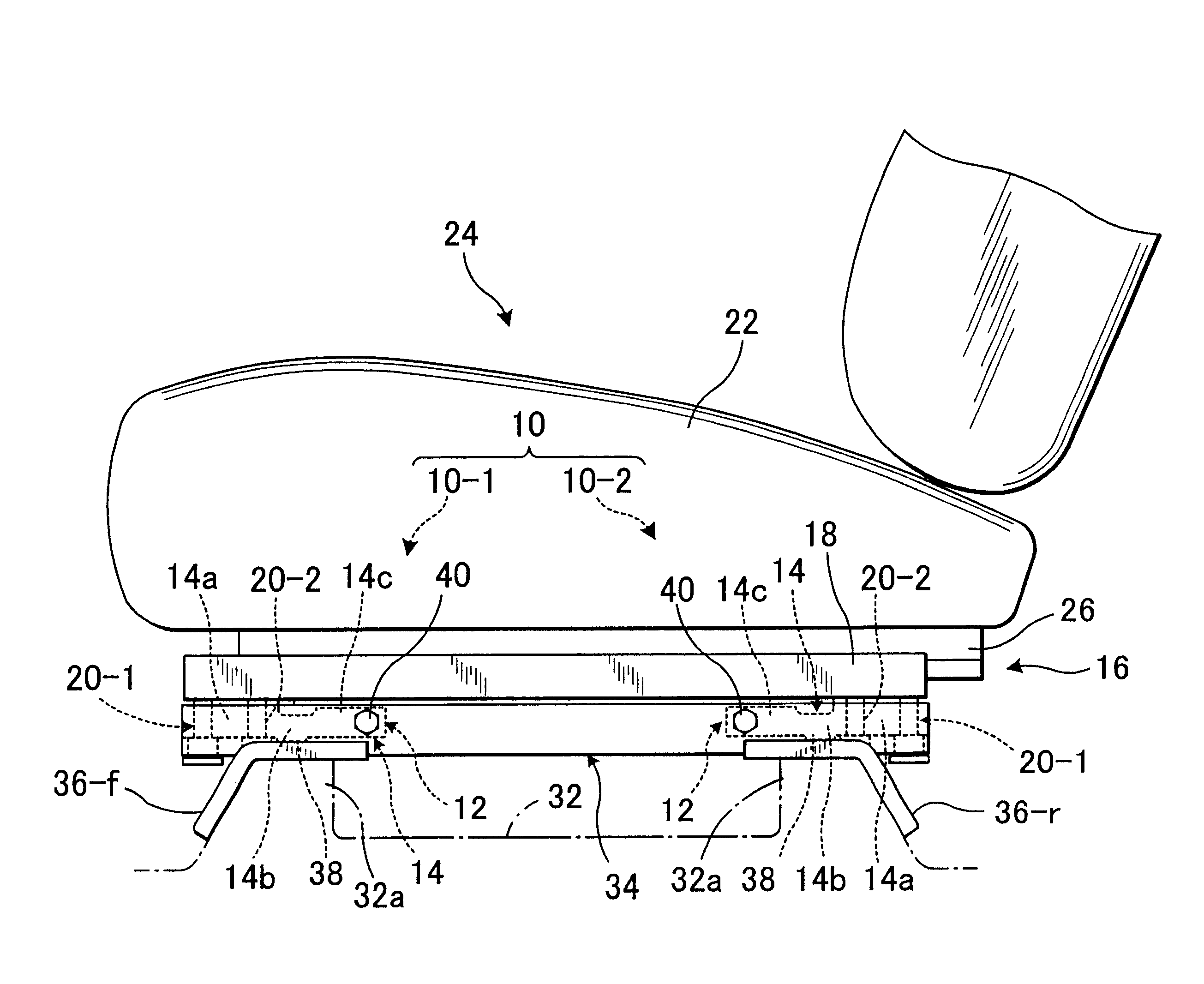

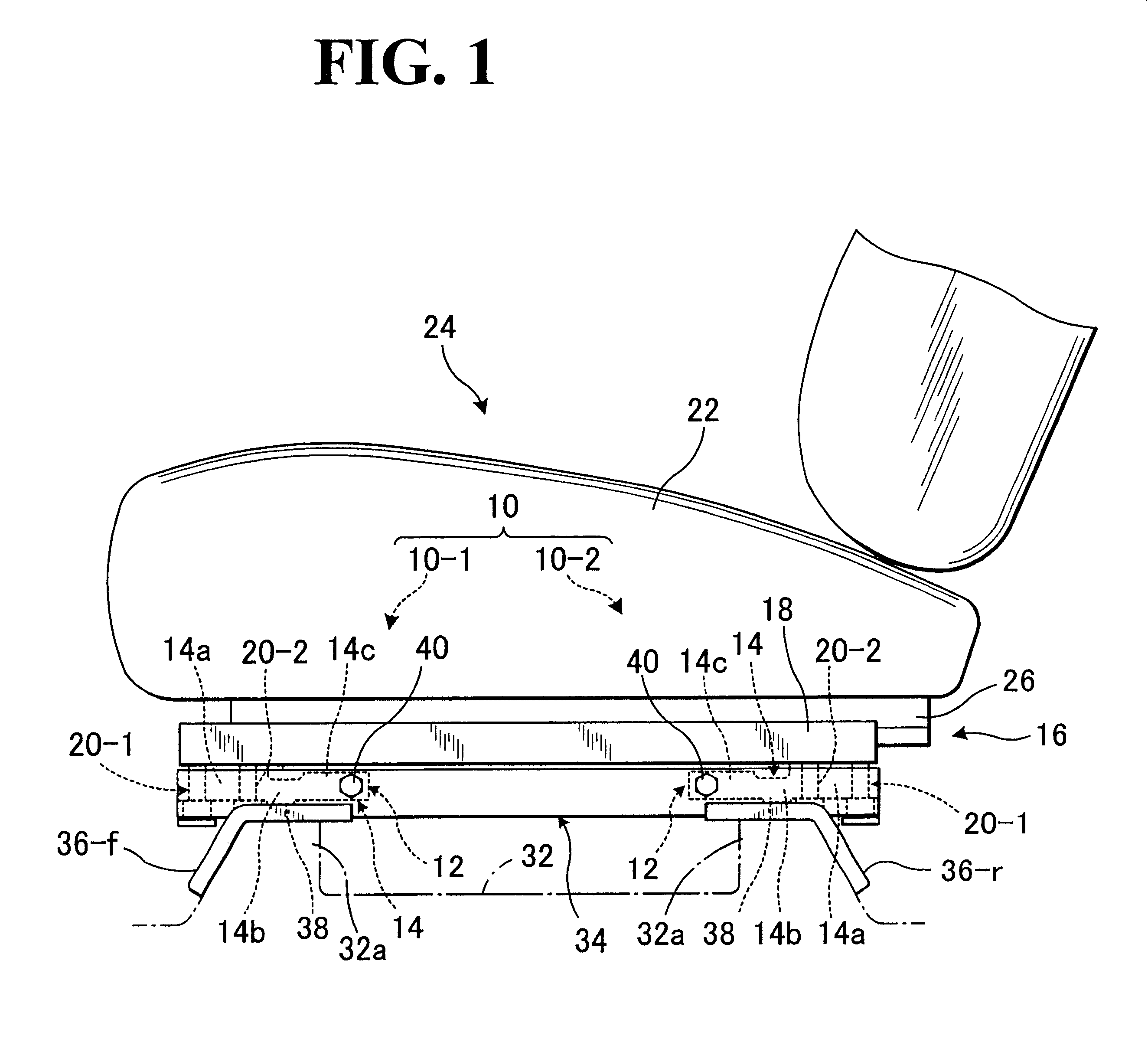

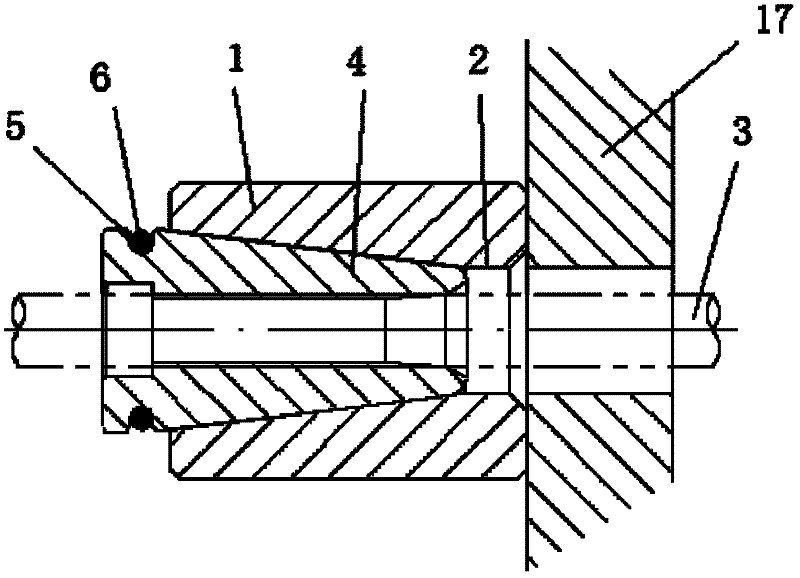

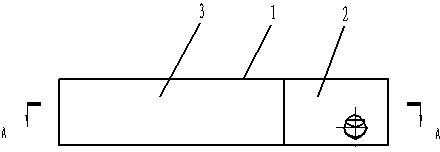

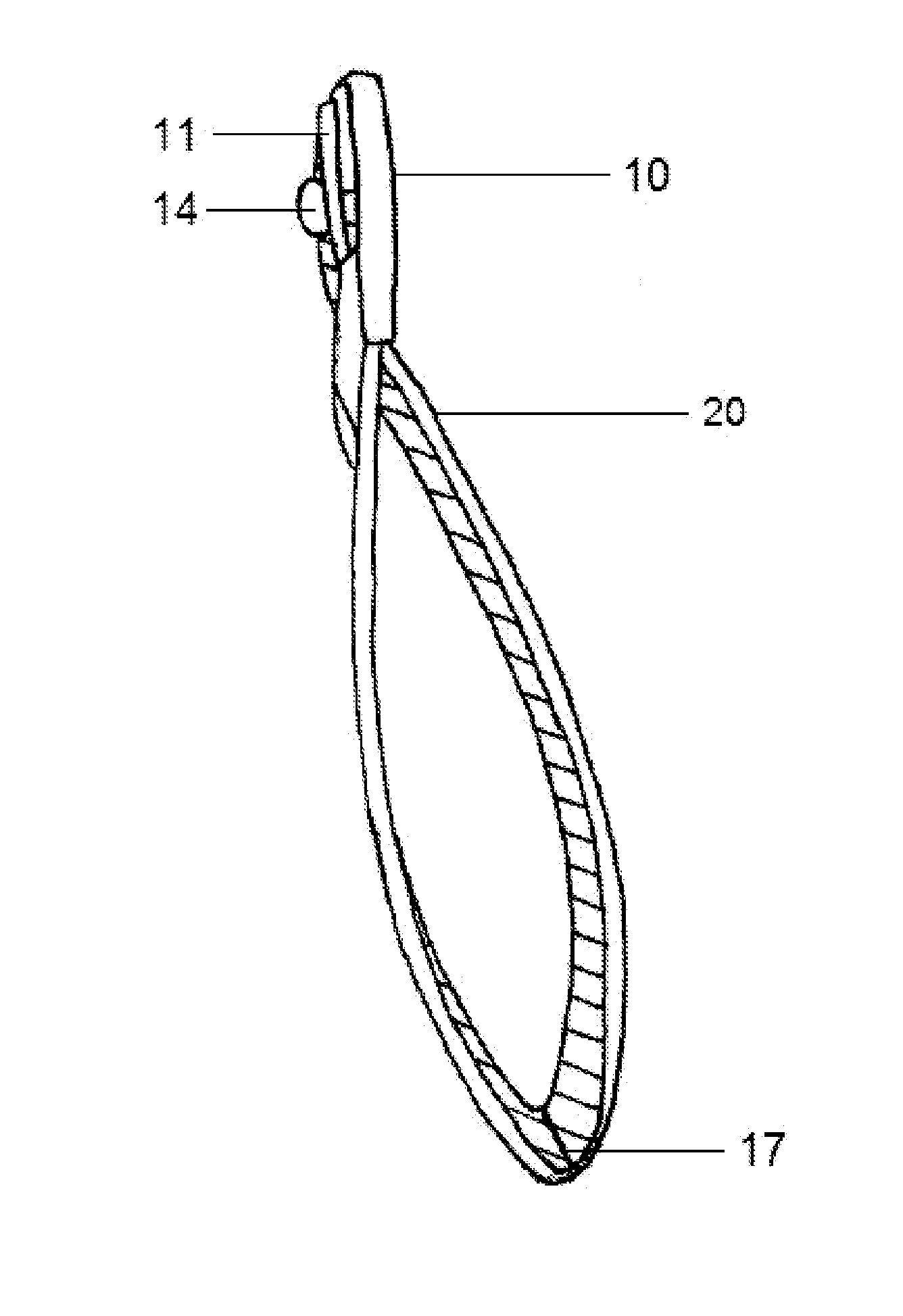

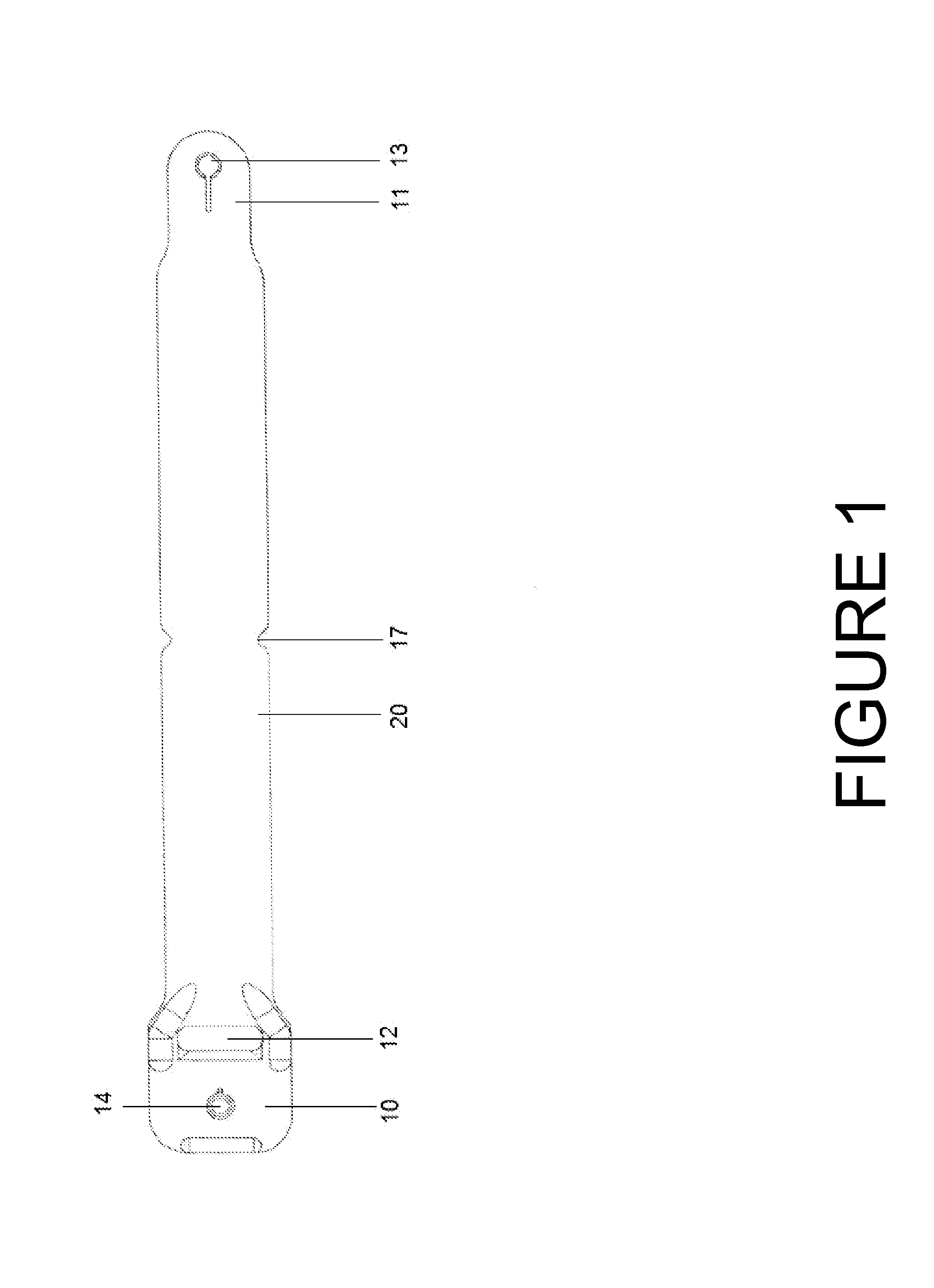

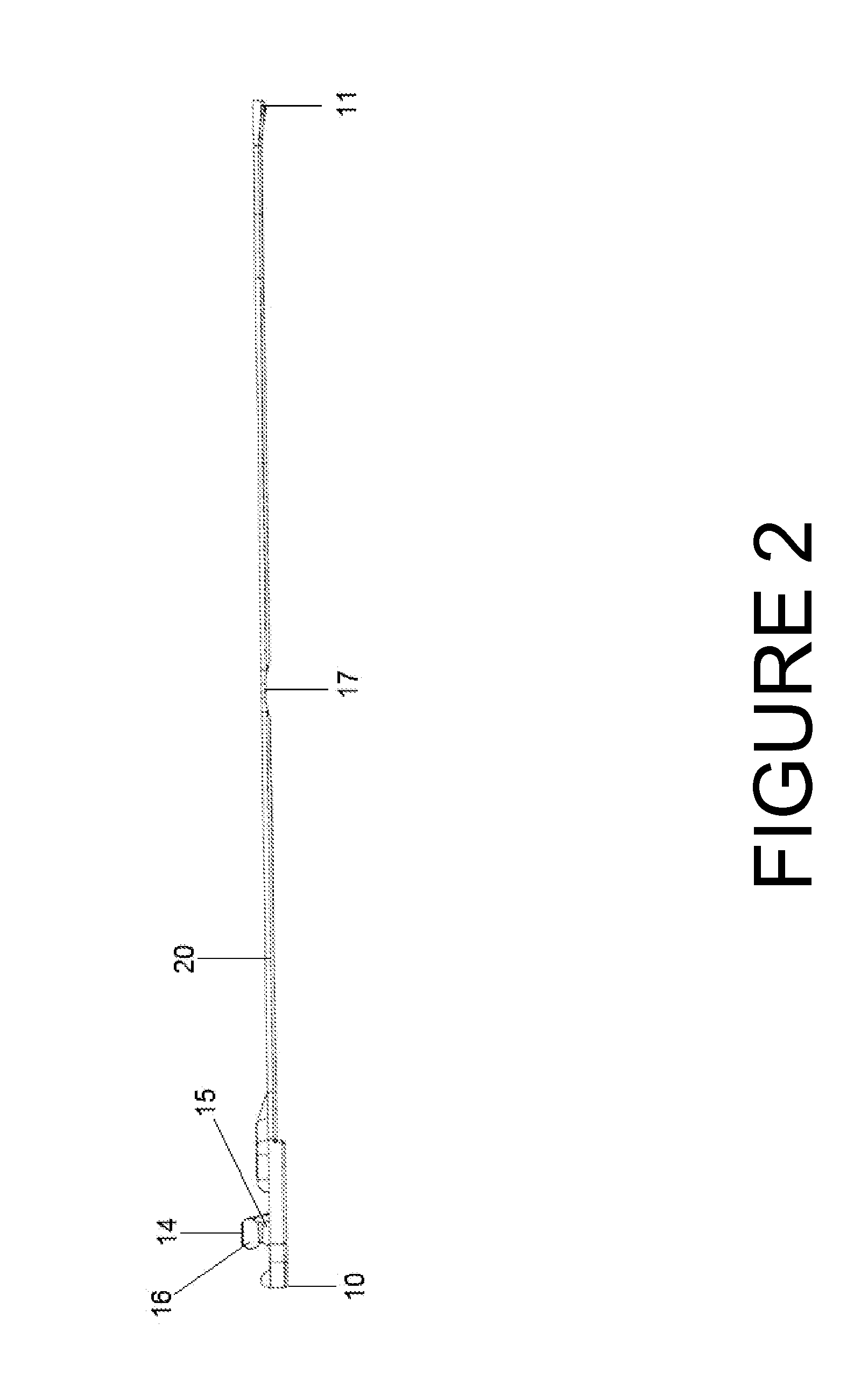

Structure for load detection element in vehicle seat

InactiveUS6695379B1Easy to moveSmooth rollingElectric devicesPedestrian/occupant safety arrangementIn vehicleEngineering

Structure for securing a load detection element under a vehicle seat in combination with a support leg element having a hole formed in one end portion thereof, wherein the load detection element is pivotally connected with the support leg element, while being fixedly secured by first and second securing pins to the vehicle seat. The first pin has an end riveted to a bottom side of the vehicle seat and an end portion extending through the hole of support leg element. Such another end portion has a head larger in diameter than that hole and is disposed outwardly under the support leg member, with one space given between the head and support leg member. The second pin has a end fused and fixed in the bottom side of vehicle seat and a head disposed beneath the load detection element, with another space given between the head and support leg member.

Owner:TACHI S CO LTD

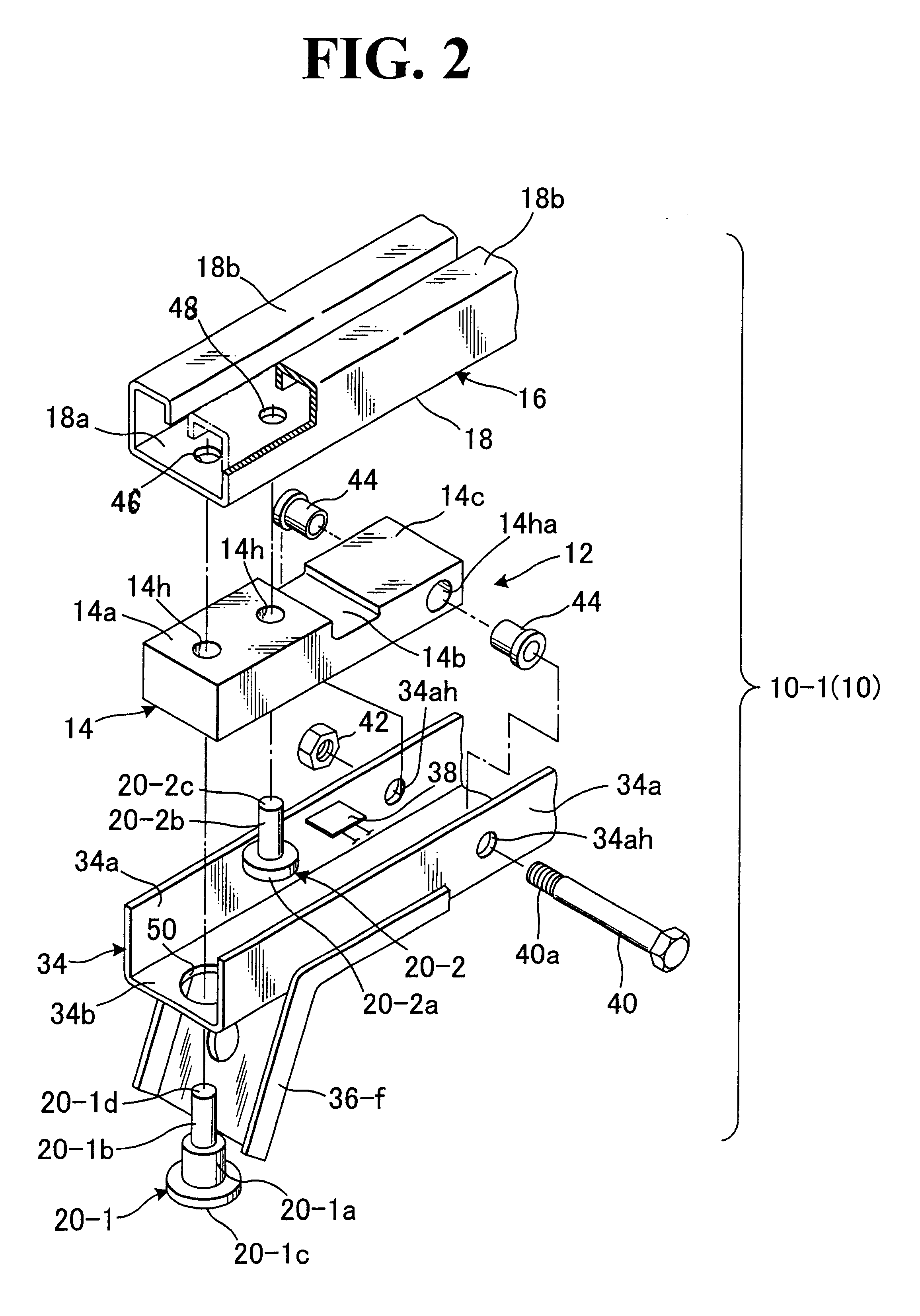

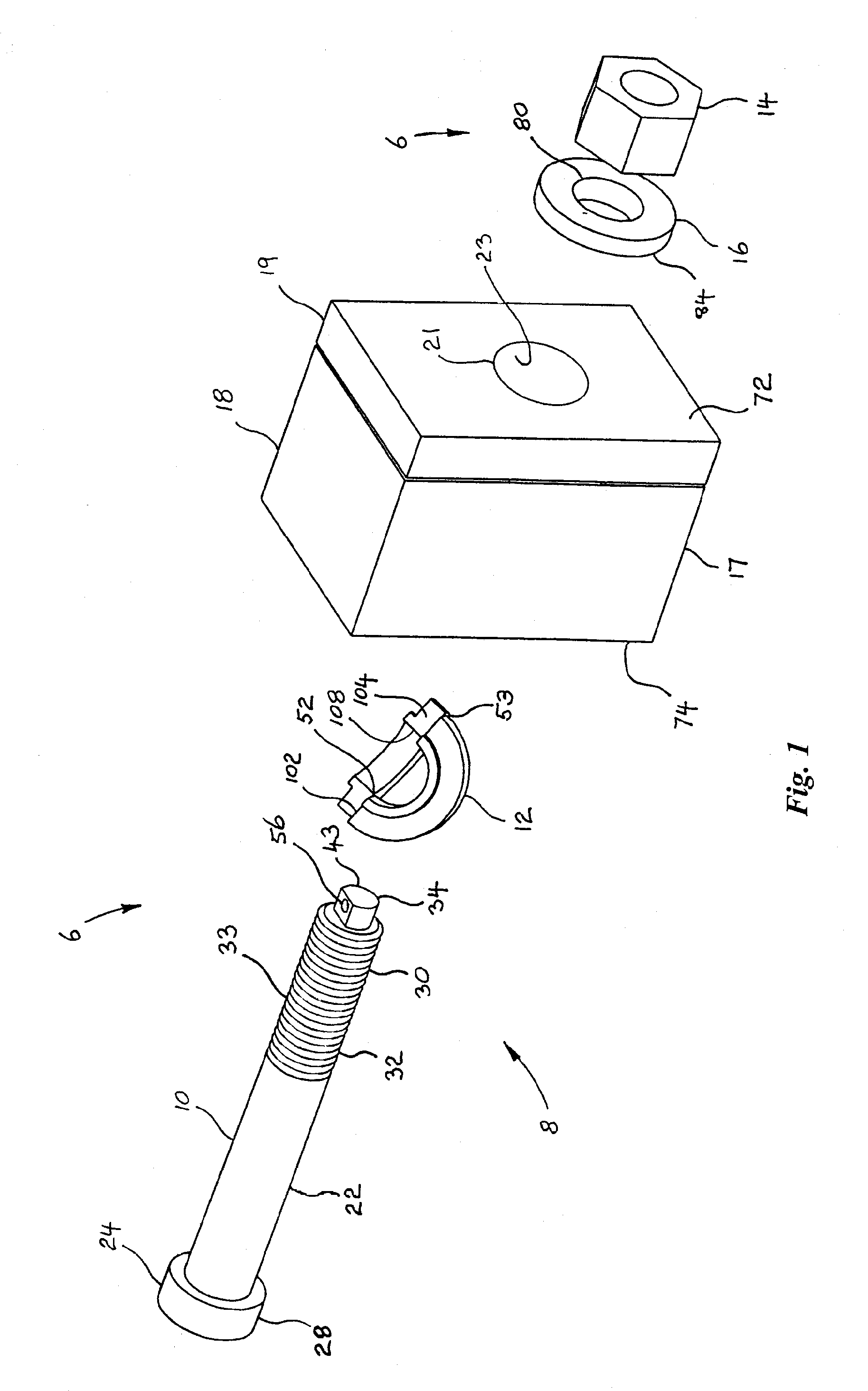

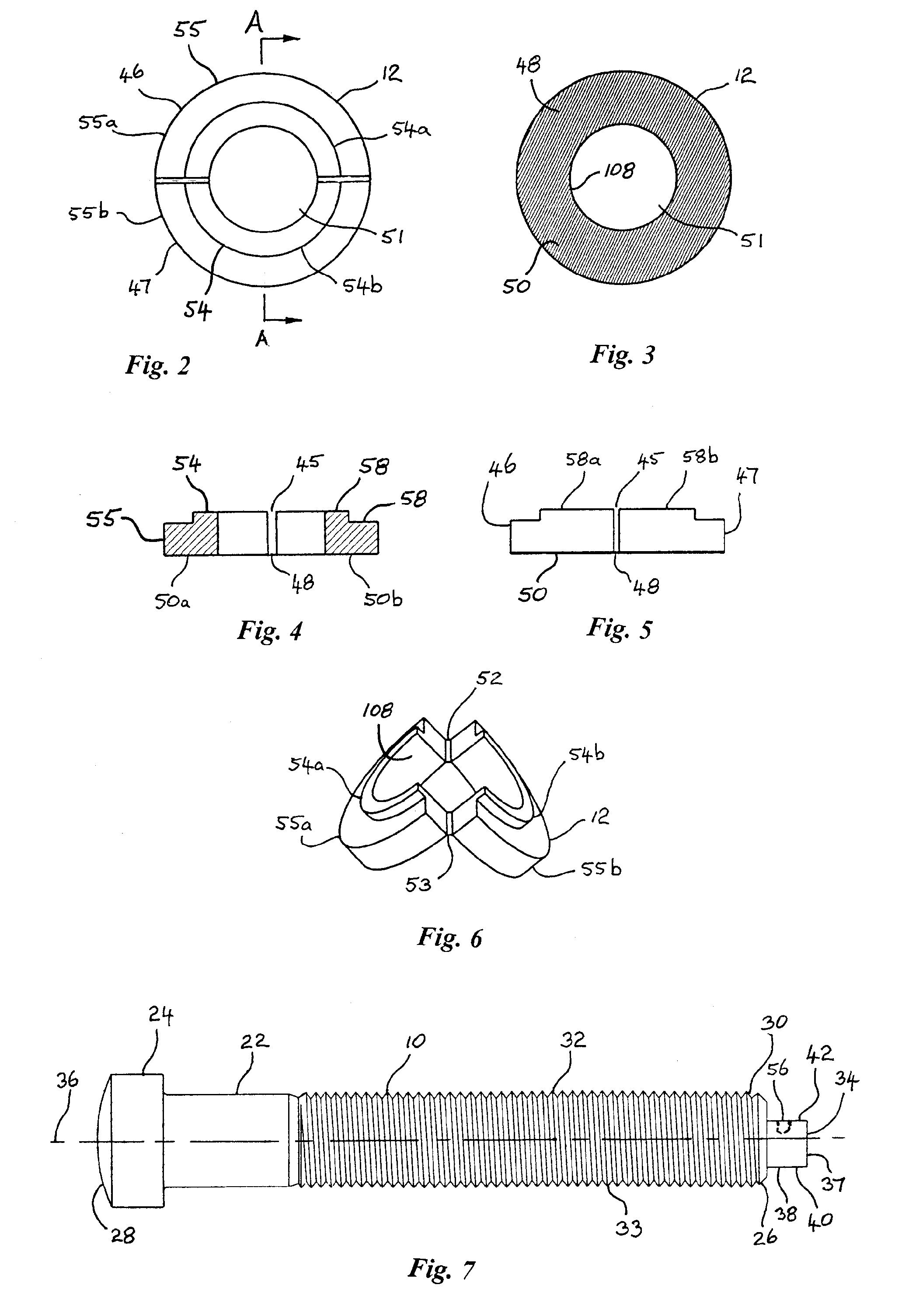

Method of installing a blind threaded fastener

Owner:IRA SVENDSGAARD & ASSOC INC +1

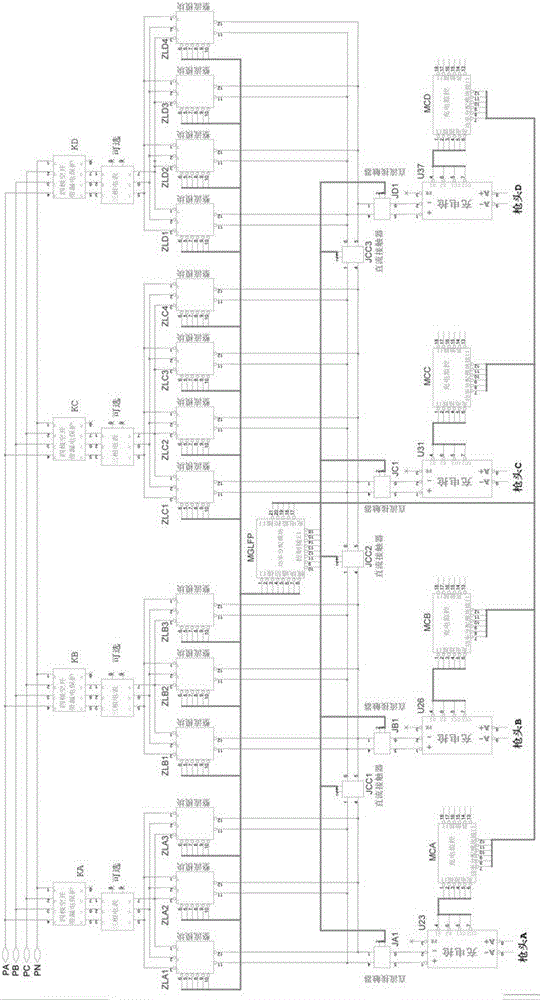

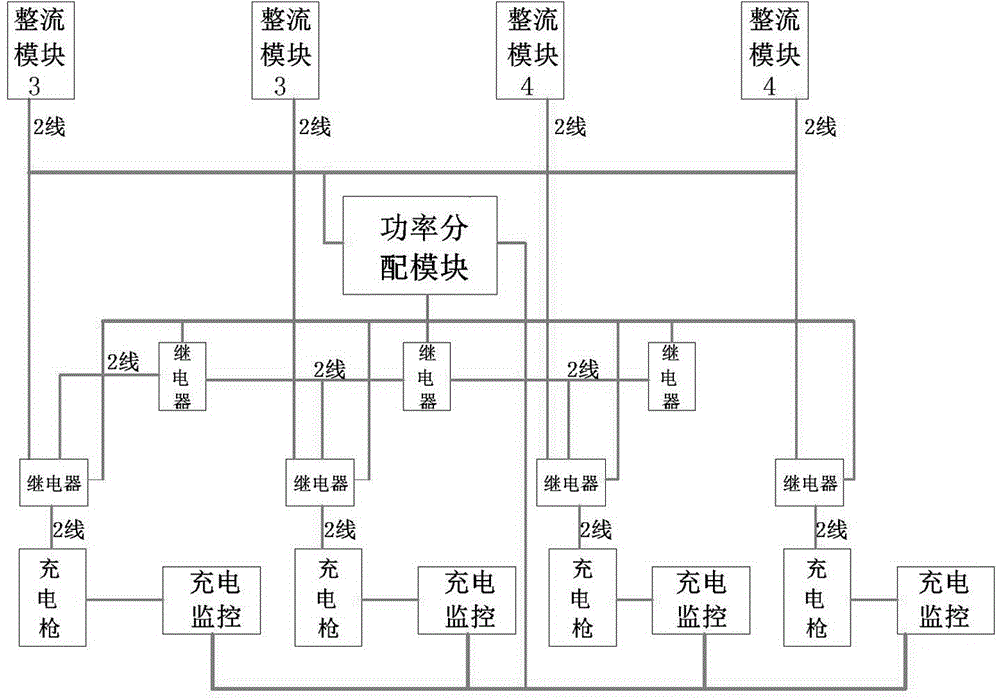

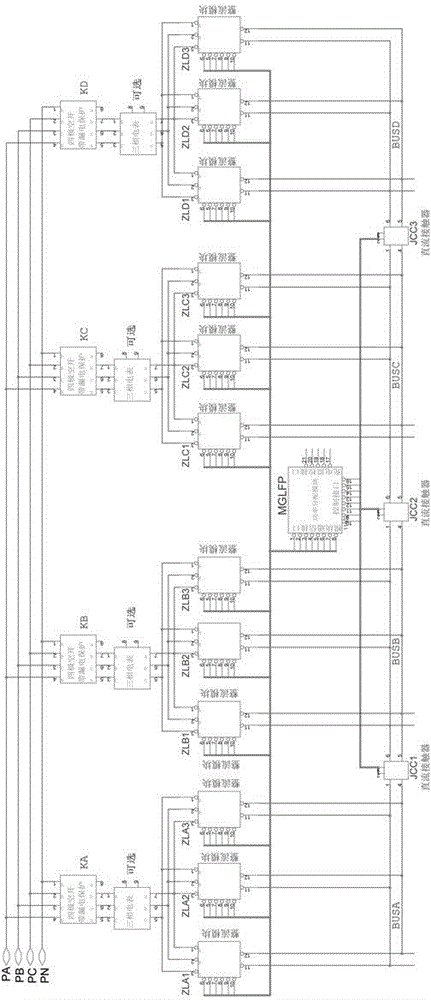

Multi-gun-head large power direct current charging pile system

ActiveCN105990883AImprove general performanceLow costBatteries circuit arrangementsElectric powerComputer moduleEngineering

The invention discloses a multi-gun-head large power direct current charging pile system. The multi-gun-head large power direct current charging pile system comprises rectification units, charging guns, electric monitoring units and a power distribution module, wherein the number of the charging guns is 2 or more than 2; the number of the rectification units are corresponding to the number of the charging guns; the power distribution module is connected with each rectification unit and each charging gun; each charging gun is connected with the power distribution module through a charging monitoring unit. The multi-gun-head large power direct current charging pile system is not only provided with a plurality of charging guns, but also is provided with the power distribution module, so that free distribution of the charging power for each charging gun is realized. For the multi-gun-head large power direct current charging pile system, the plurality of gun heads can charge multi kinds of vehicles at the same time, such as a large vehicle, a mini-bus and a small vehicle. Practice has proved that the multi-gun-head large power direct current charging pile system has the advantages of being high in practicability, reliability and universality, saving the cost and the space, being high in the utilization rate, and being low in investment.

Owner:肖伟

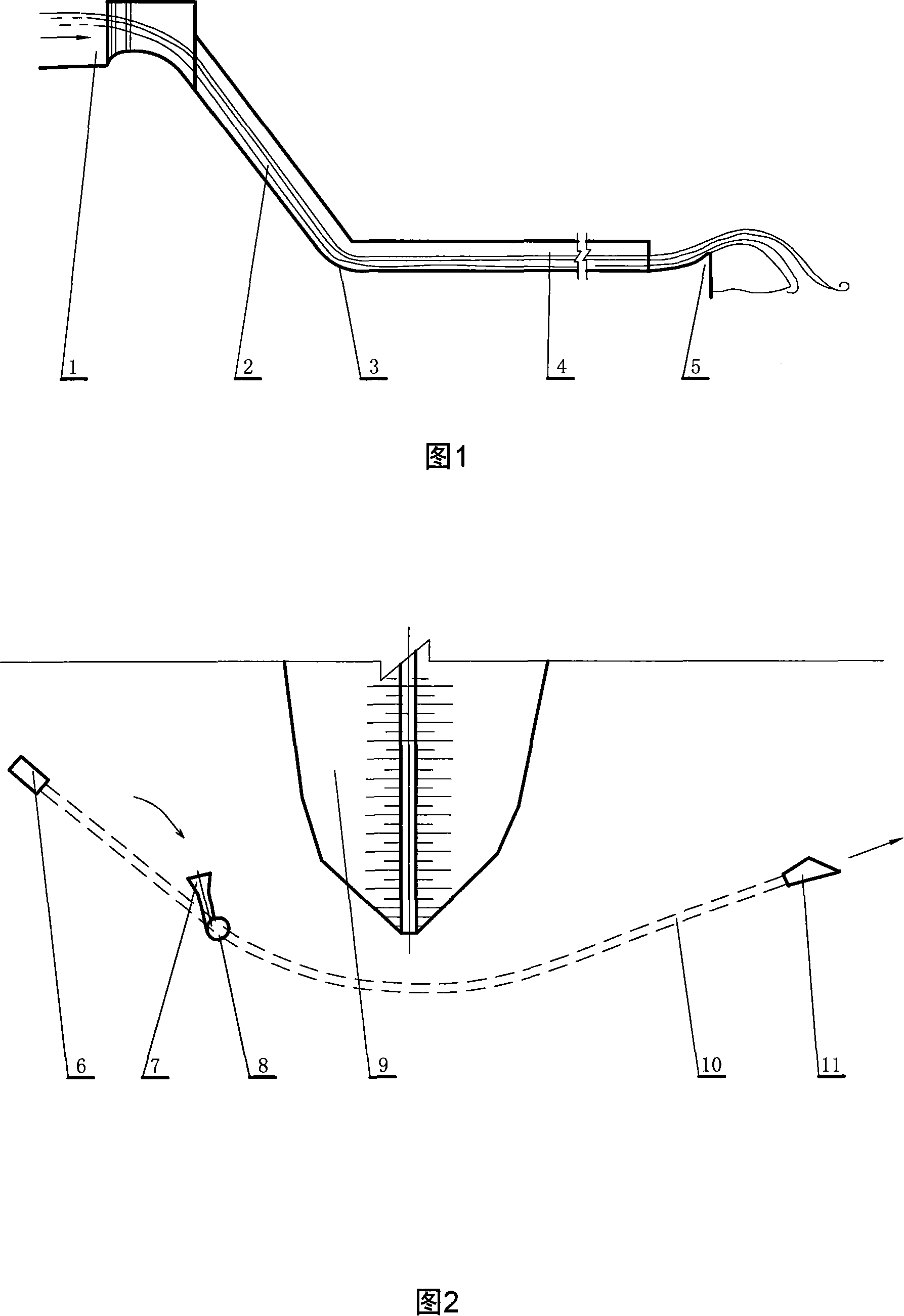

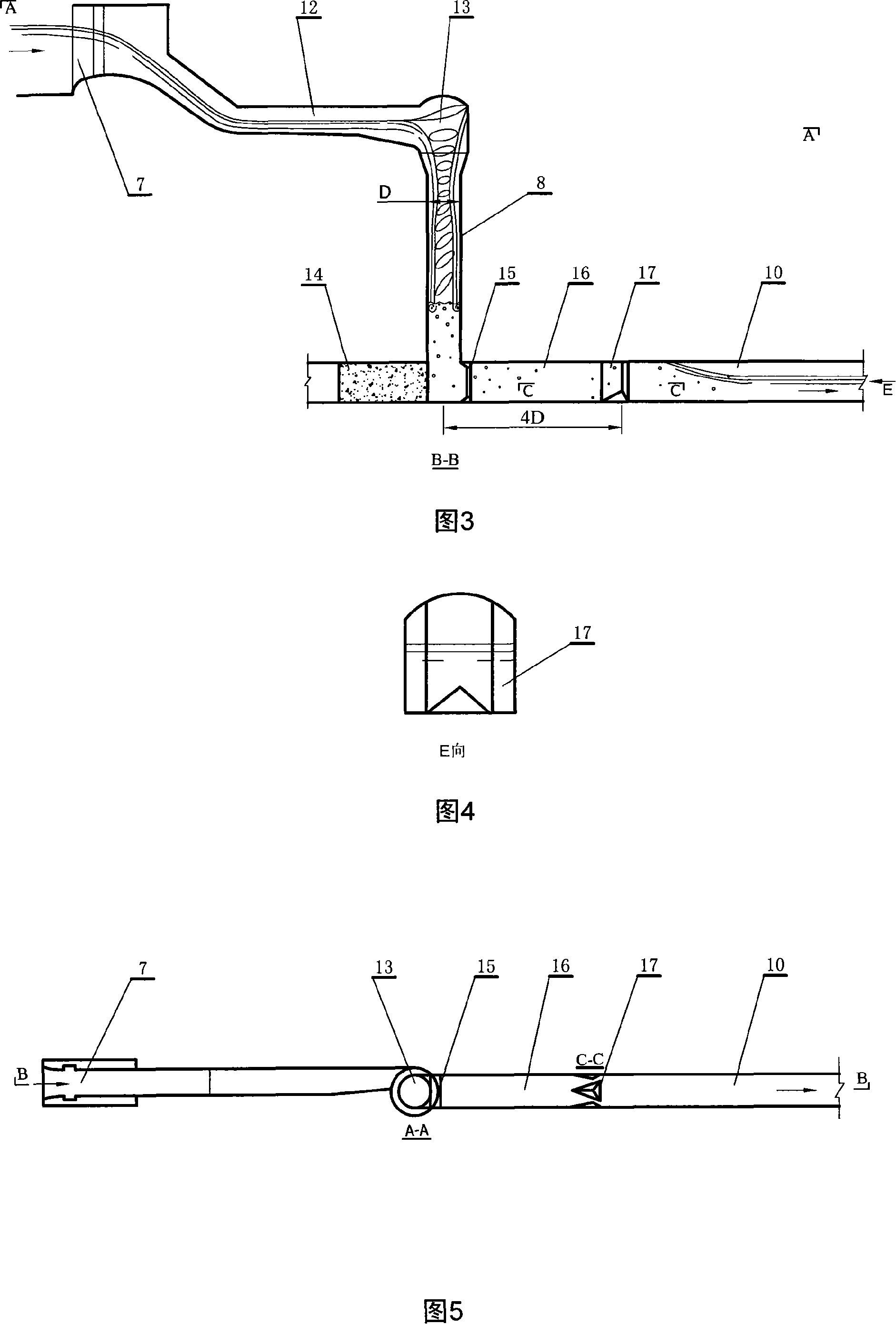

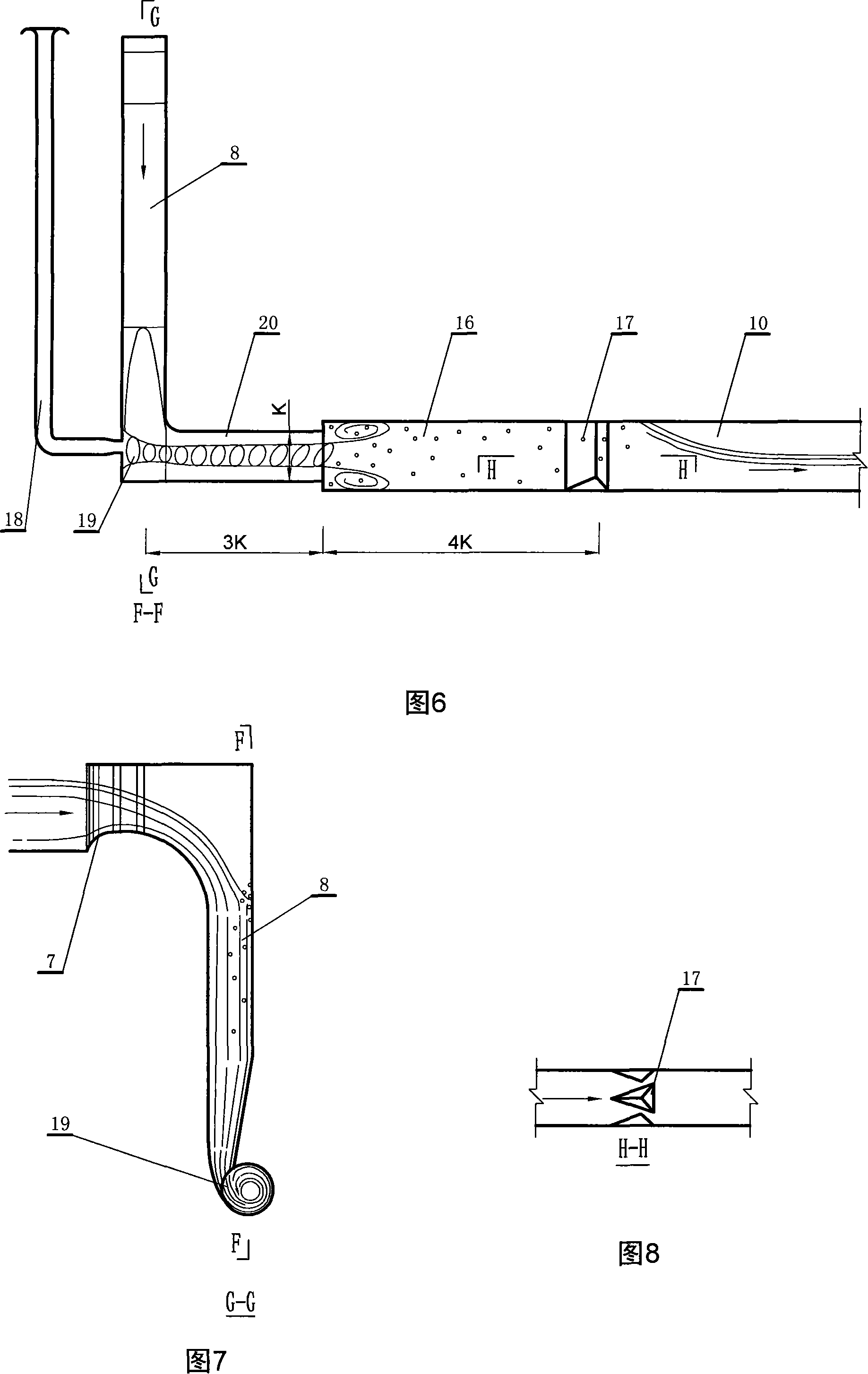

Flood discharging method and flood discharging tunnel employing rotational flow and strong moisture mixing energy dissipation

The present invention relates to flood discharge method and flood discharge tunnel dissipating energy by means of eddying flow and intense water-air mixing, and is especially one flood discharge tunnel for high water head large hydraulic power project. The flood discharge tunnel includes one water inlet in the upstream of dam, one eddy flow and fall head energy dissipating facility connected to the water inlet and provided with well, one water cushion pond with one waterproofing pier in the exit for further energy dissipating, one water output tunnel connected to the water cushion pond and one water outlet. The flood discharge tunnel has one energy dissipating rate as high as 90 %, and can control the outlet flow rate and prevent cavitation erosion, scouring and atomizing effectively.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

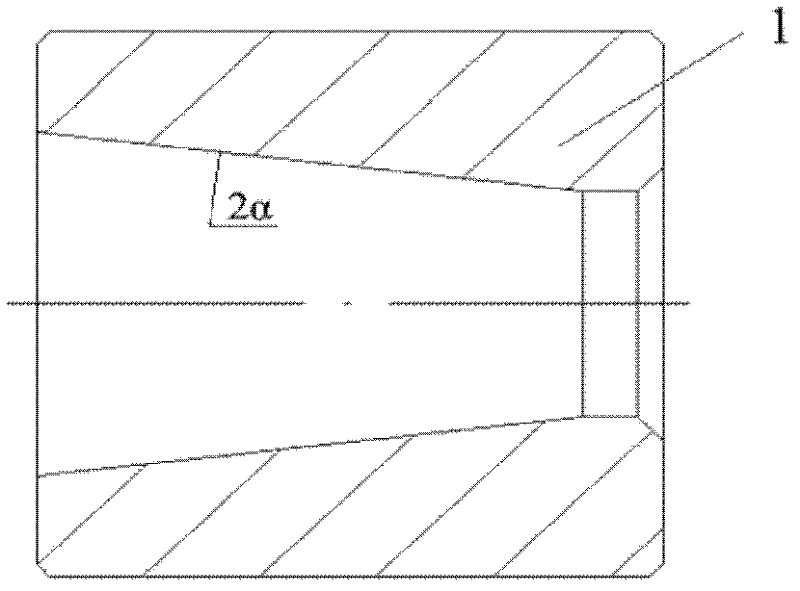

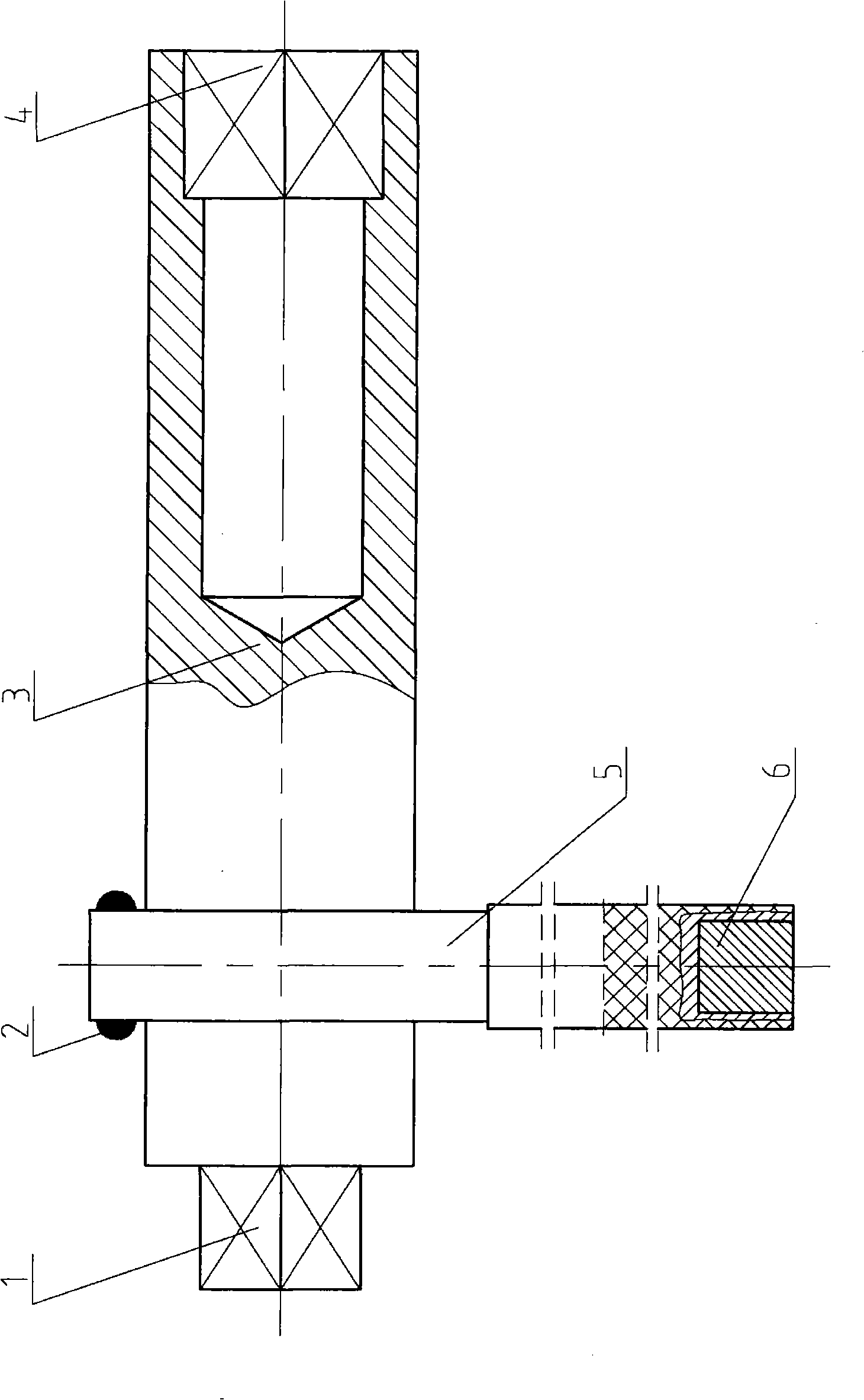

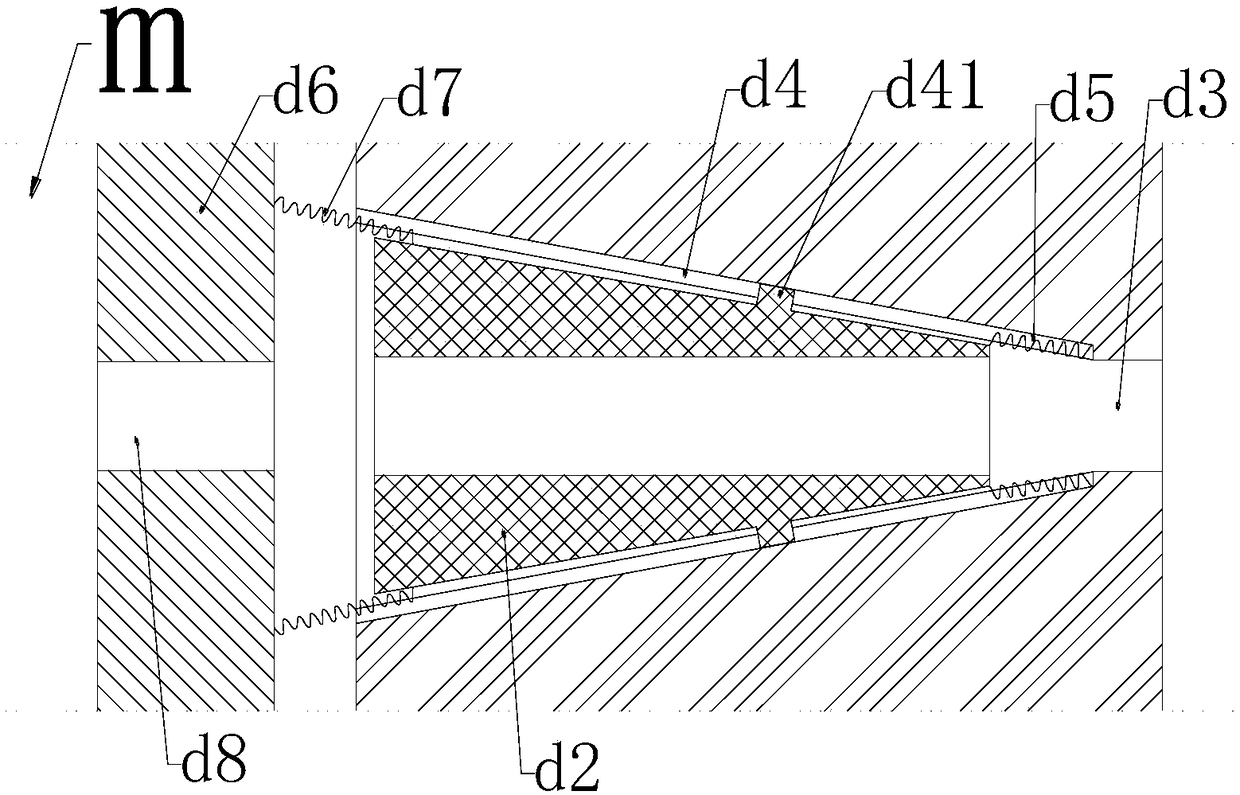

Pretensioning clamp for heat treated steel bars with high ratio of tensile strength to yield point and application method thereof

InactiveCN102359231AAvoid pinchingPrevent bitingBuilding reinforcementsBuilding material handlingPre stressEngineering

The invention relates to a pretensioning clamp for heat treated steel bars with a high ratio of tensile strength to yield point and an application method thereof. The clamp is characterized in that: the clamp comprises a cylinder-shaped anchor ring; the internal diameter of the anchor ring is a taper hole; three clamping pieces mutually forming an angle of 120 degrees are provided in the taper hole; the outer wall of the big-head end of the clamping pieces is provided with a concave groove; an O-shaped sealing ring is arranged in the concave groove to allow the three clamping pieces to connect and form an integral body; the inner wall of each clamping piece is provided with screw teeth, and a radial cross section of the screw teeth is of a zigzag shape. The invention enables anchoring of steel bars with high ratio of tensile strength to yield point during tensioning to be well realized; the clamp has a great clamping force on the steel bars and high anchoring efficiency, and is repeatedly usable. The clamp can be widely used in pretensioning construction of prestressed concrete in the constructional field.

Owner:CABR TECH CO LTD +1

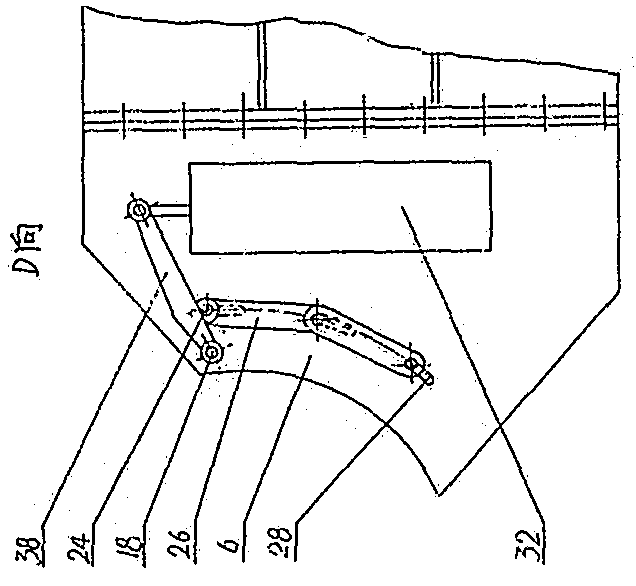

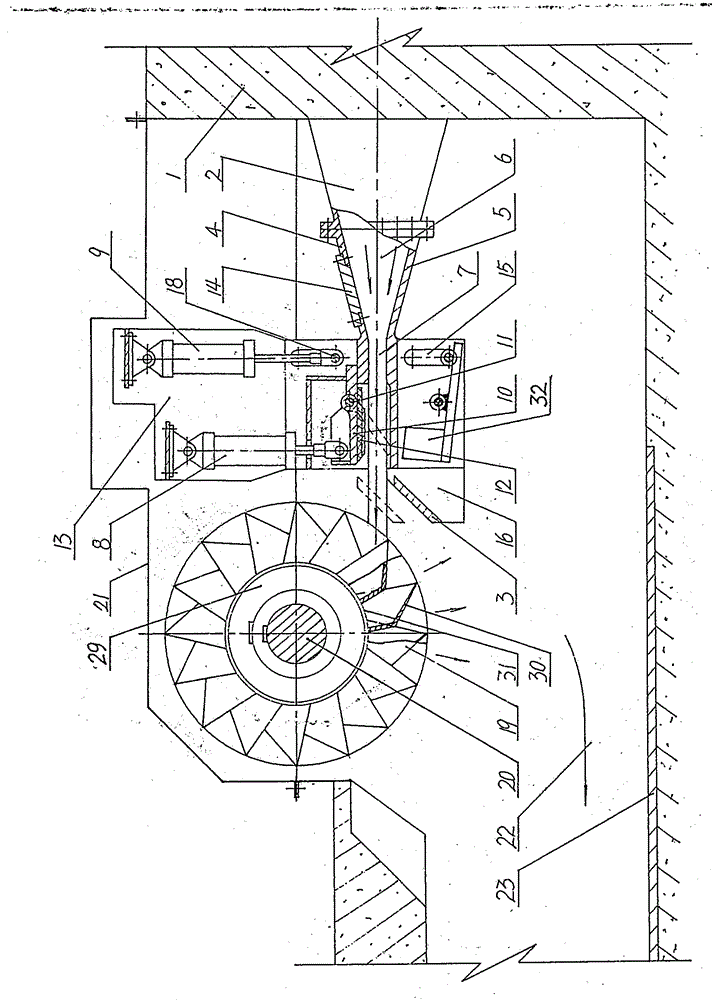

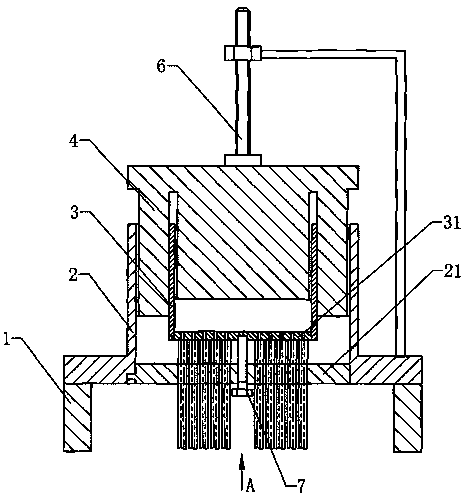

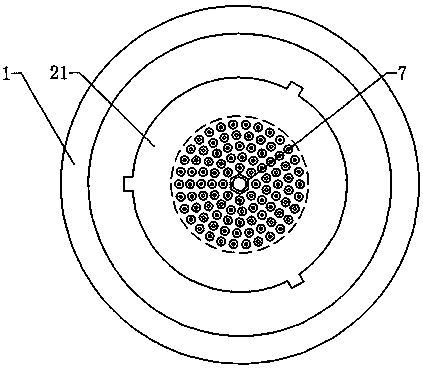

Water turbine

InactiveCN105370478AAuto excludeSignificant progressHydro energy generationSafety/regulatory devicesWater turbineWater flow

The invention relates to an impact type water turbine in the technical field of hydraulic electrogenerating. The water turbine is mainly composed of an ejection device and a rotation device, wherein the ejection device is mainly composed of a base plate, a top plate, lateral plates on the two sides and components such as an ejection opening formed by a rotary valve hinged to the water outlet end of the top plate or the base plate and a transmission component of the rotary valve; and the rotation device is formed by components such as a wheel disc or hub arranged on a main shaft, a plurality of blades which are arranged on the outer surface of the wheel disc or hub, the shape of the surface between the two sides is a groove, outer end guide plates arranged on the outer end faces of the groove-shaped blades, inner end guide plates arranged on the inner end faces of the groove-shaped blades and the like, wherein the shape of the surface between the two sides of each blade is in a groove shape. By means of the water turbine, the water flow pressure energy can be efficiently converted into rotary mechanical energy, and the water turbine can be suitable for low-water-head large-flow water energy resources.

Owner:黄国宏

Bolt assembly for the attachment of toilet seats and other articles

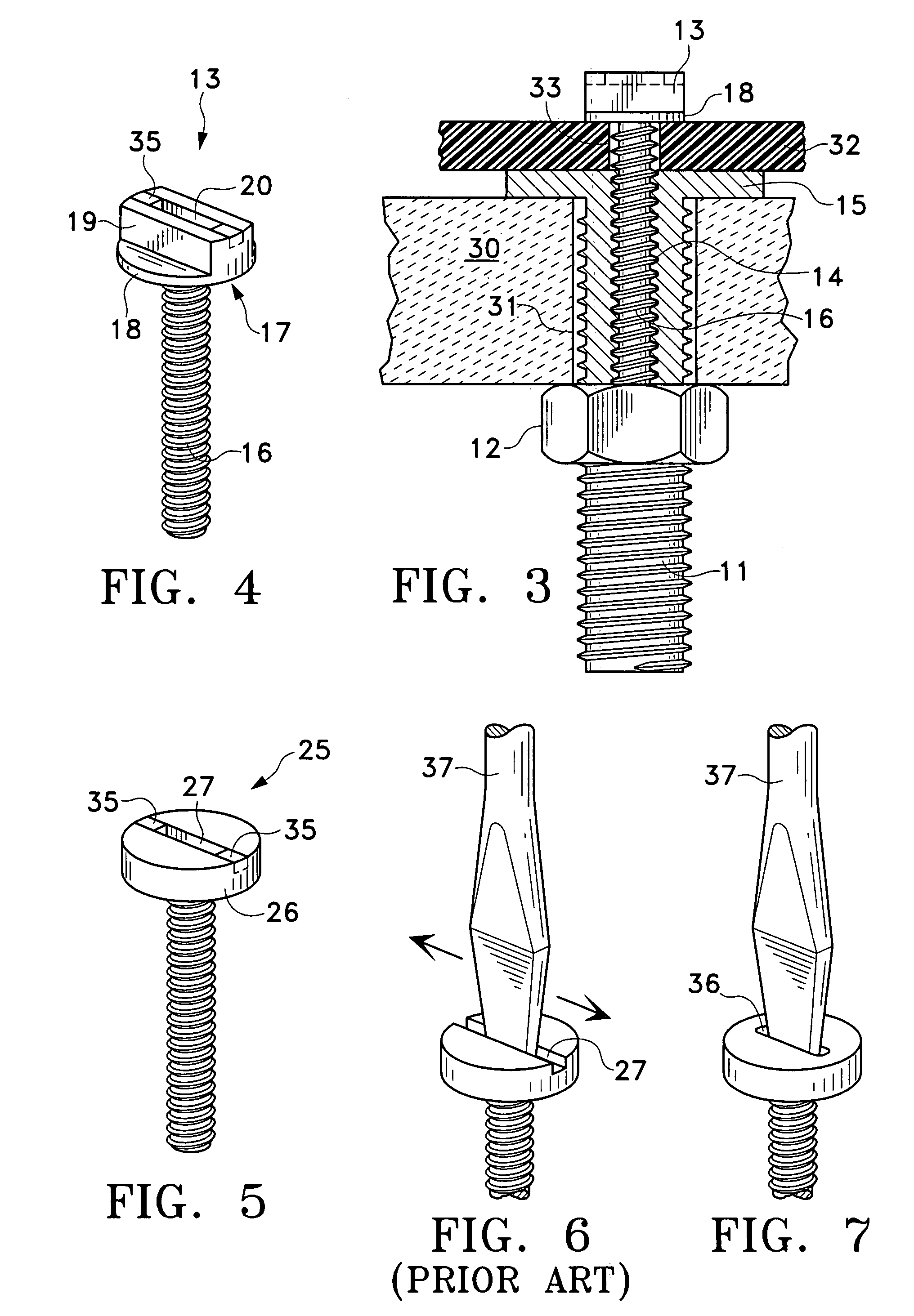

A bolt assembly for use with toilet seats and other objects consists of a threaded bolt with a threaded axial bore and a head larger than the opening in the toilet bowl flange, a nut sized to fit the bolt, and a screw dimensioned to cooperate with the bore. The bolt is inserted through the opening in the flange, extending there beyond. The bolt is secured from below the flange with the nut. The seat assembly is then placed on the flange so that the aperture in the seat assembly bracket communicates with the threaded bore. The seat assembly is secured in place by passing the screw through the aperture in the bracket and threading it into the bore. The seat assembly can then be reversibly removed for cleaning by merely removing and replacing the screw without having to reach under the flange. The screw can have a gripping head so that it can be rotated without the need for a screwdriver, or there can be a slot centered on the top of the head so that a screwdriver can be used. The slot can be sized to accept a screwdriver but such that it will not permit the screwdriver to slip sideways during use.

Owner:RICHTER MILTON

Relation to Blind Bolting

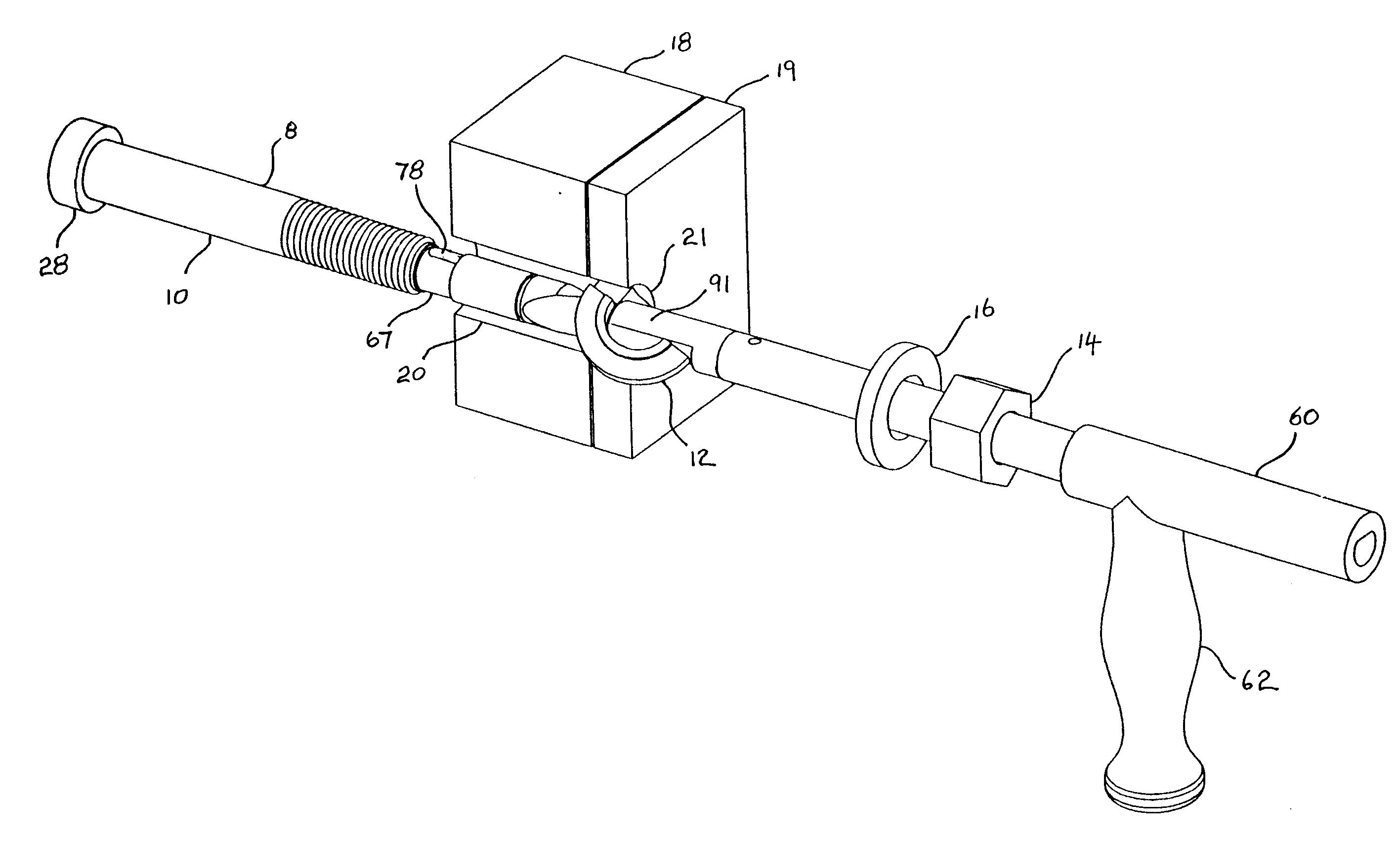

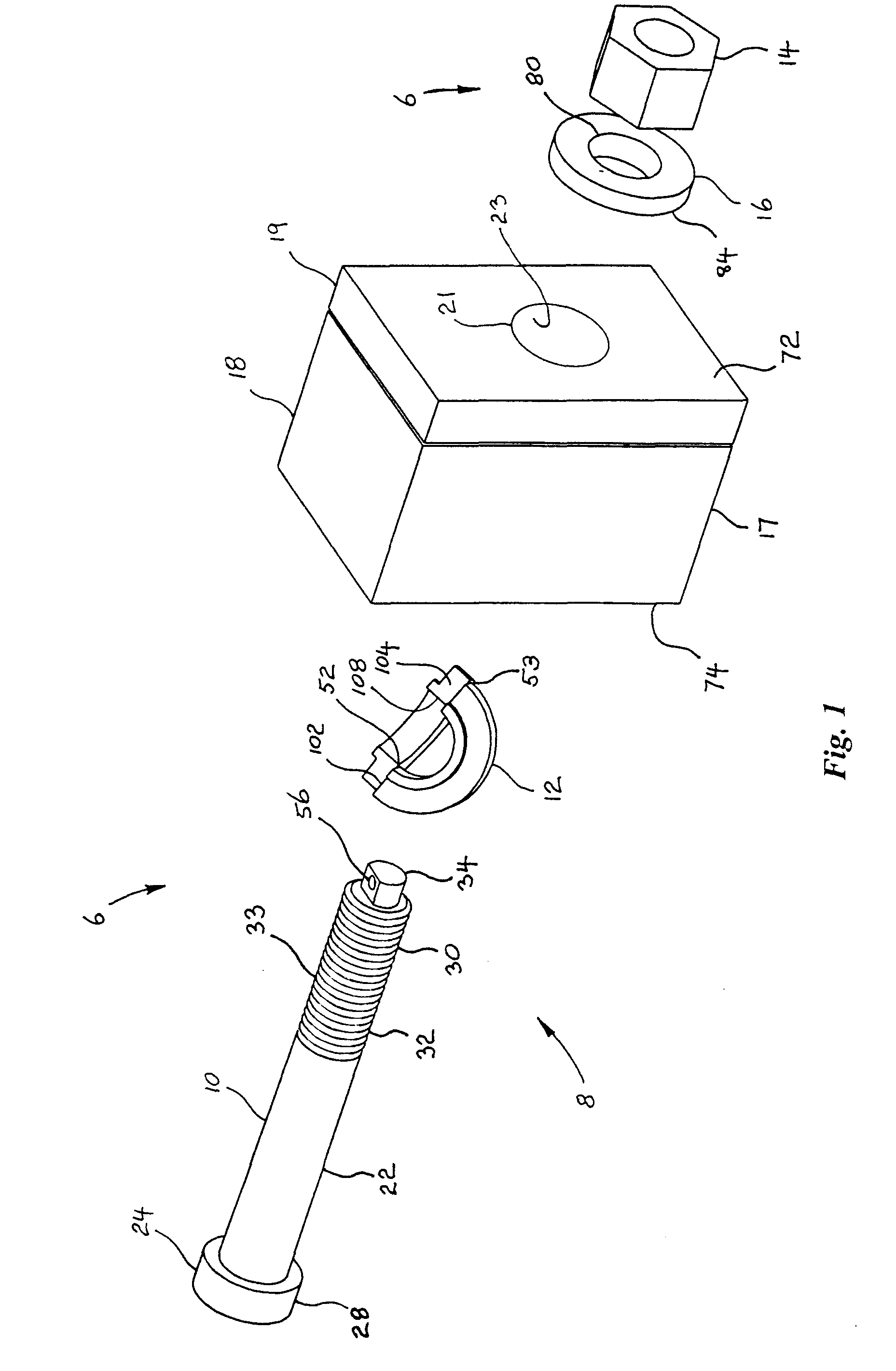

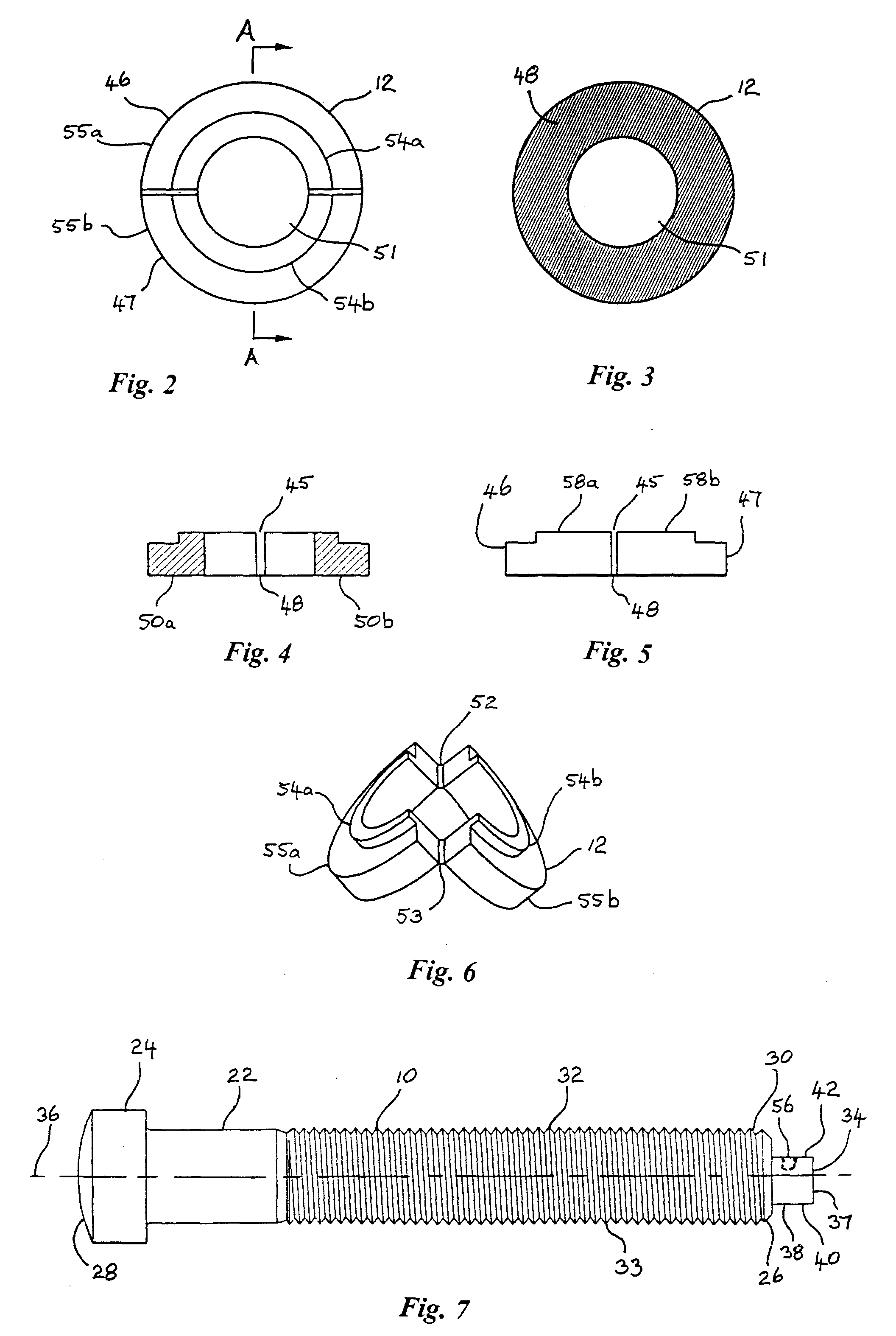

A method of installing a threaded fastener from one side of a hole through a substrate. The fastener includes a collar and a bolt having a head, a threaded tail portion and a tool engagement portion extending from the tail. The method includes: (a) engaging the tool engagement portion with a bolt engagement portion of a tool (b) passing the bolt through to the far side of the hole and supporting it there by way of the tool, (c) passing the collar through the hole while supporting it with the tool; (d) assembling the bolt and collar to form the threaded fastener having a head larger than the hole; (e) engaging a nut to tighten the fastener; and (f) detaching the tool from the fastener. Separation of the bolt engagement portion and the tool engagement portion is prevented by a moveable member, which engages both portions.

Owner:IRA SVENDSGAARD & ASSOC INC +1

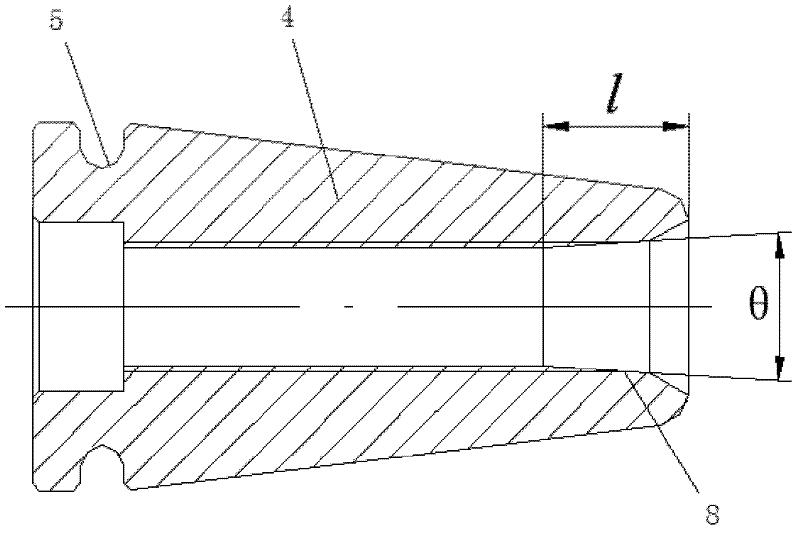

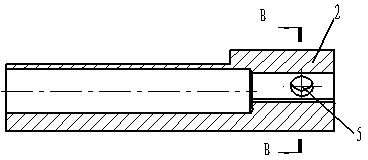

Device and method for machining high-speed turning multi-head large-lead deep-groove-type external threads

ActiveCN103286389AImprove processing efficiencyImprove surface qualityThread cutting machinesEngineeringScrew thread

The invention discloses a device and method for machining high-speed turning multi-head large-lead deep-groove-type external threads. The device comprises a hollow cutter body. The cutter body is composed of a cutter installation part and a clamping part. A square hole and a screw hole communicated with each other are formed in the clamping part, wherein the square hole is used for clamping a cutter and the screw hole is used for fixing the cutter. The device further comprises a tip with end teeth. The tip with the end teeth comprises a hollow tip body. A fixing screw hole is formed in one end of the tip body. A positioning circular protrusion is formed at the other end of the tip body, wherein the diameter of the positioning circular protrusion is smaller than that of the tip body. The end teeth which are evenly distributed at the circumference are formed at the portion, arranged on the periphery of the positioning circular protrusion, of the tip body. The method comprises the following steps: (i) beginning, (ii) roughly turning an external circle, (iii) roughly turning the threads, (iv) half-finely turning the threads, (v) finely turning the threads, (vi) finely turning the external circle and (vii) finishing. According to the device and method for machining the high-speed turning multi-head large-lead deep-groove-type external threads, machining efficiency and the spiral surface quality of the multi-head deep-groove-type threads are greatly improved.

Owner:CHINA NUCLEAR TIANJIN TECH DEV

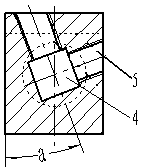

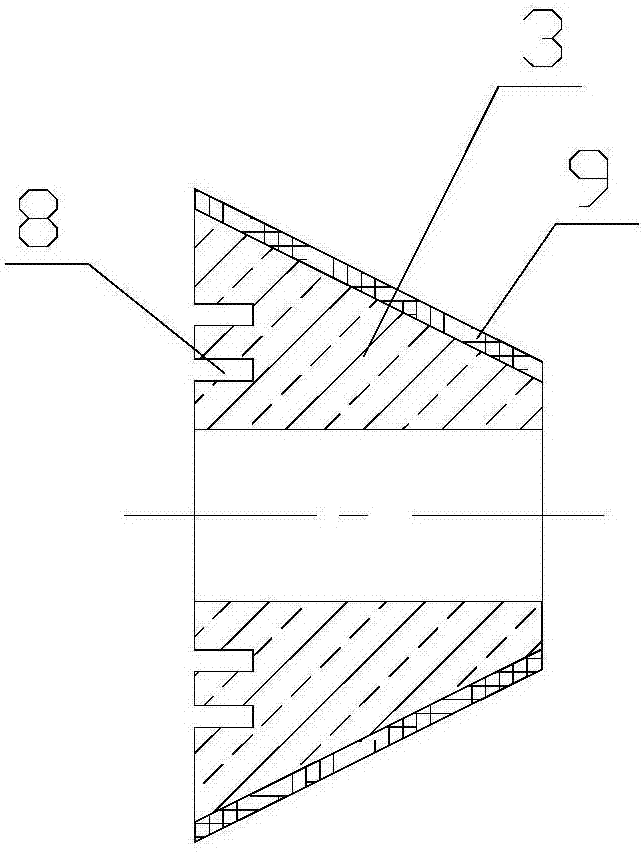

Polycrystalline diamond contact for well drilling and rock crushing tool

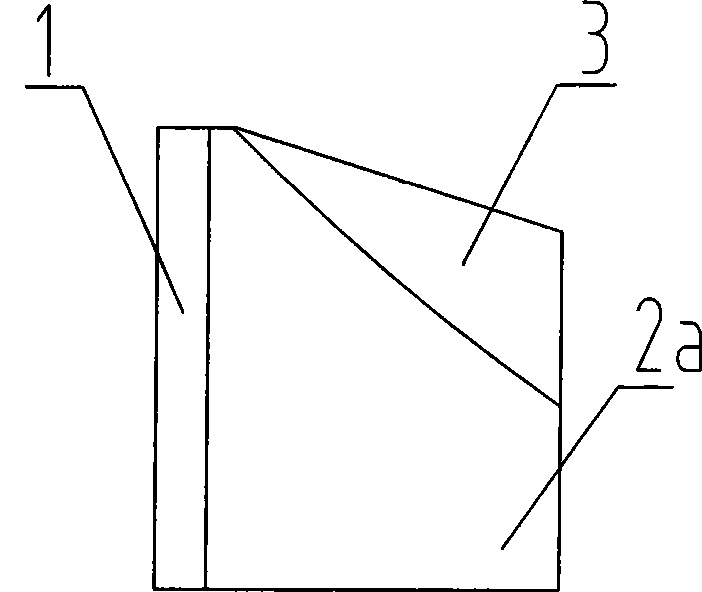

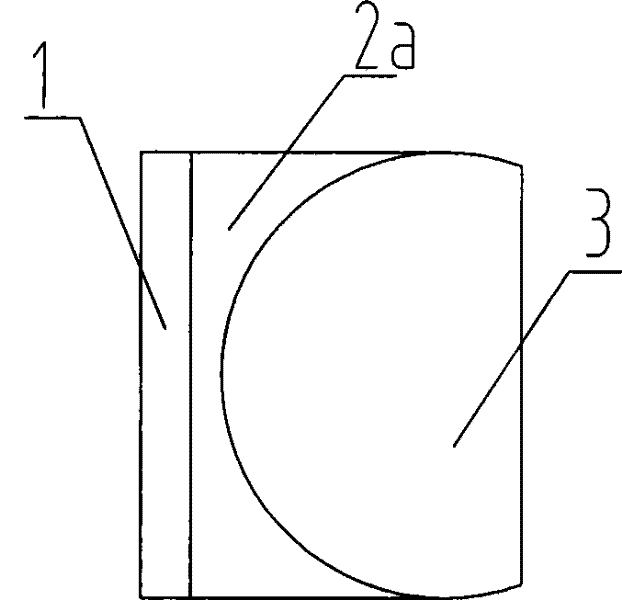

InactiveCN101748974AEnhanced ability to eat into the groundReduce pressure areaDrill bitsWell drillingPolycrystalline diamond

The invention discloses a polycrystalline diamond contact for a well drilling and rock crushing tool, which is a cylindrical body and comprises a polycrystalline diamond layer (1) and a matrix (2) compounded with the polycrystalline diamond layer (1). The matrix of the compact consists of the residual part of a convex curved surface after being cut along an inclined direction, the side face after cutting consists of an original cylindrical surface (2a) and a new convex curved surface (3), a body of the compact has a large end and a small end, wherein the end with the polycrystalline diamond layer (1) is the large end, and the other end is the small end. Compared with the conventional structure, the invention reduces the contact possibility of the side face of the compact and a rock (7). In addition, when the compact is worn during the cutting of the rock (7), the bearing area of the worn surface of the PDC compact can be reduced, and the specific pressure on the rock interacting with the worn surface of the PDC compact can be increased, thereby facilitating the strengthening of the capability of the compact to penetrate into the formation and improving the rock crushing efficiency of the drill bit.

Owner:SOUTHWEST PETROLEUM UNIV +1

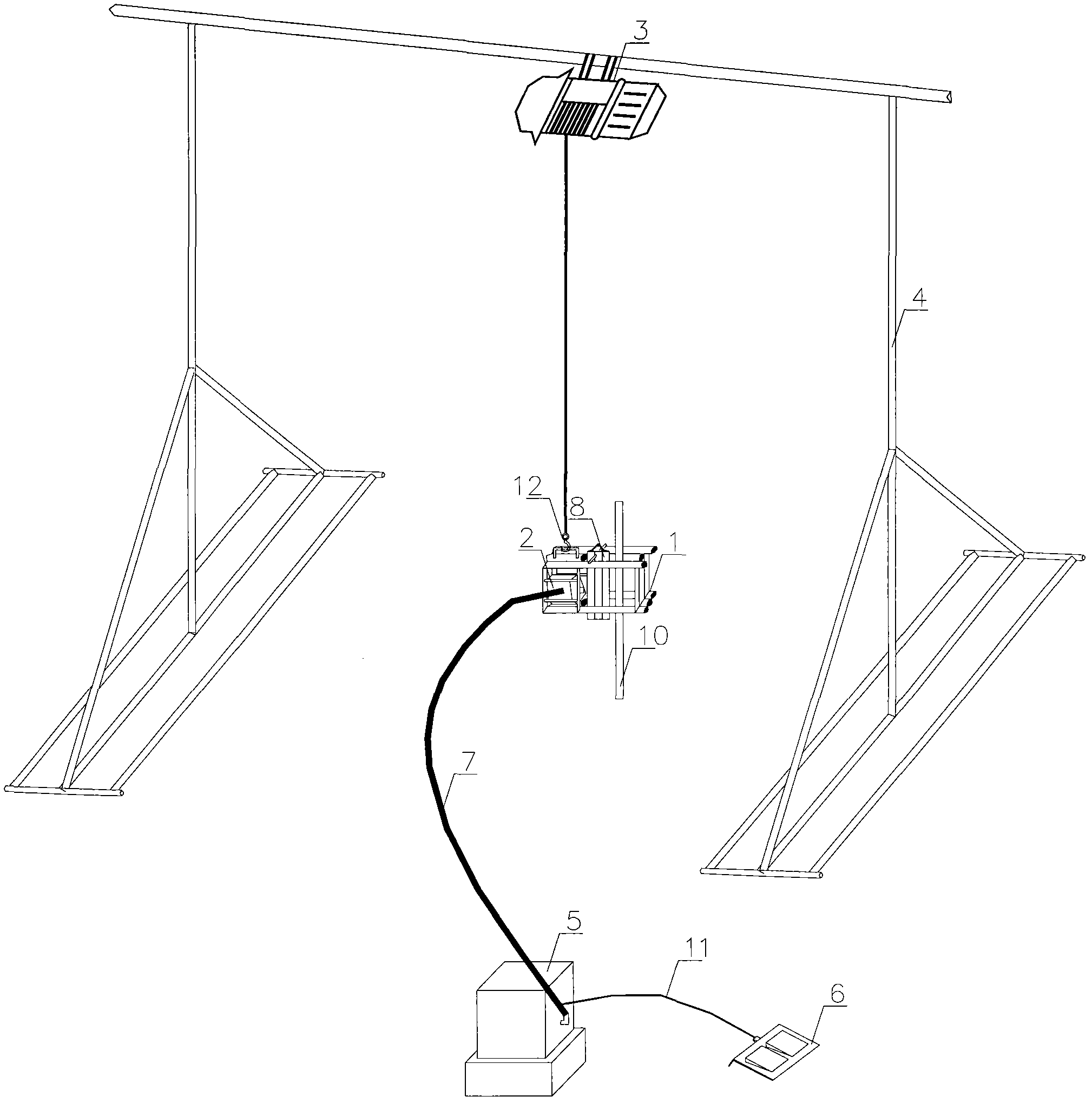

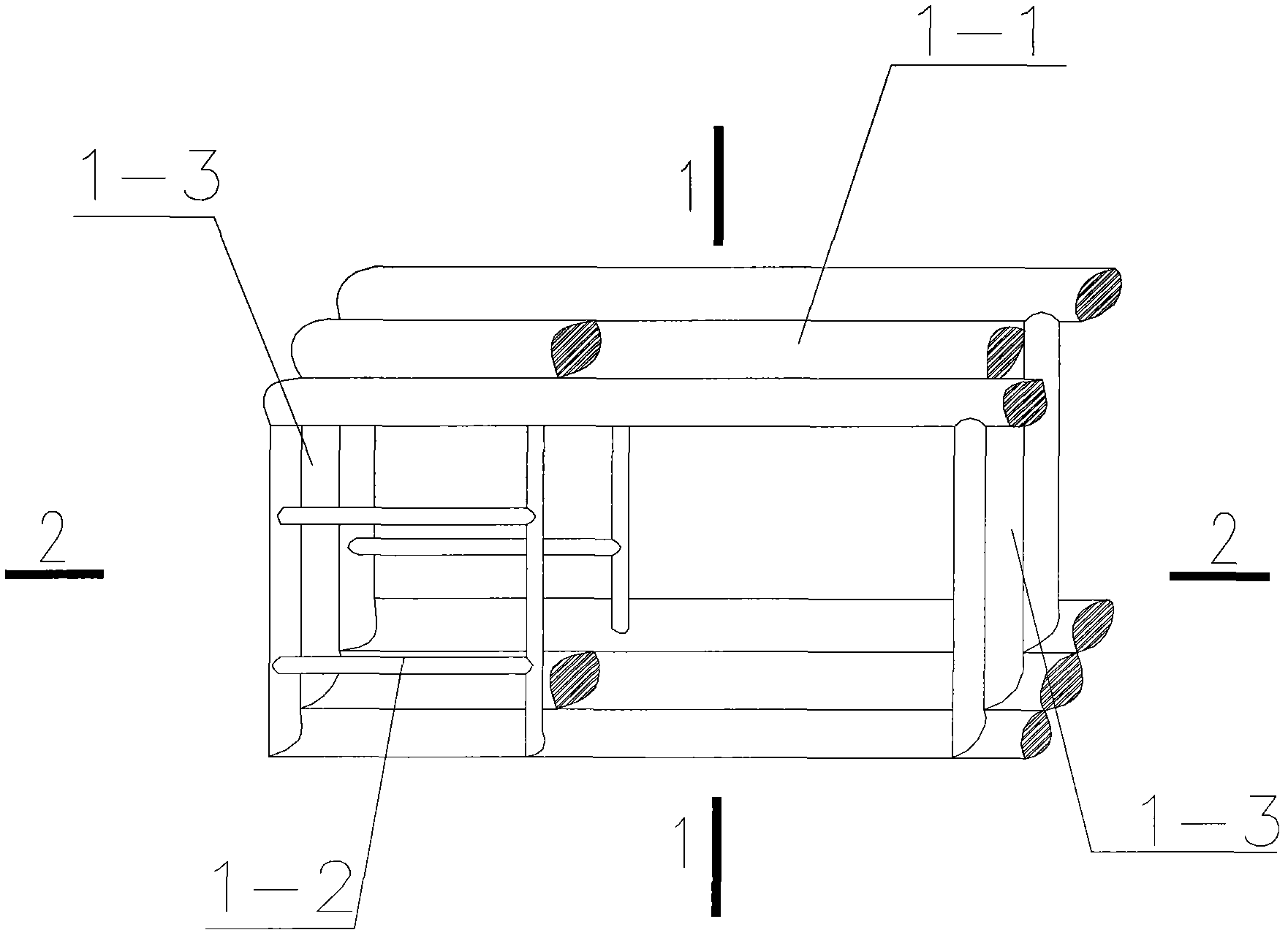

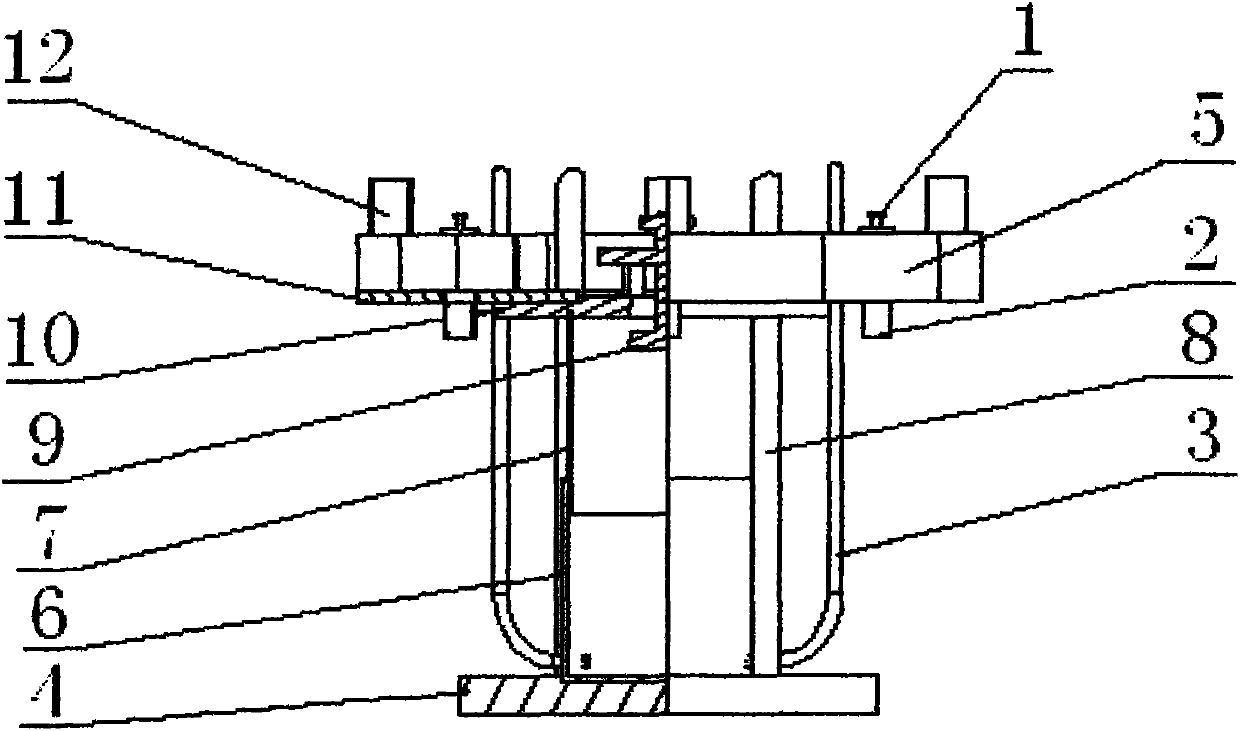

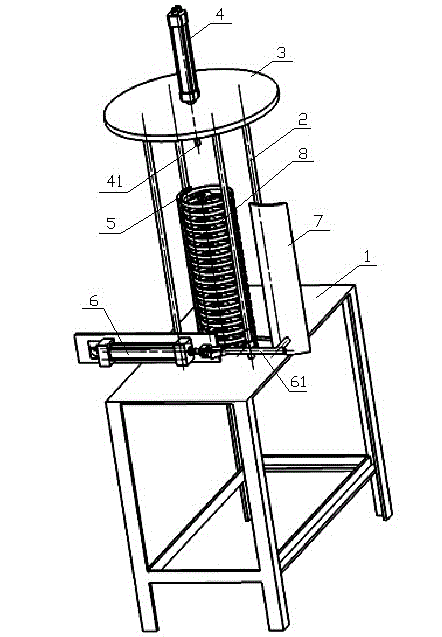

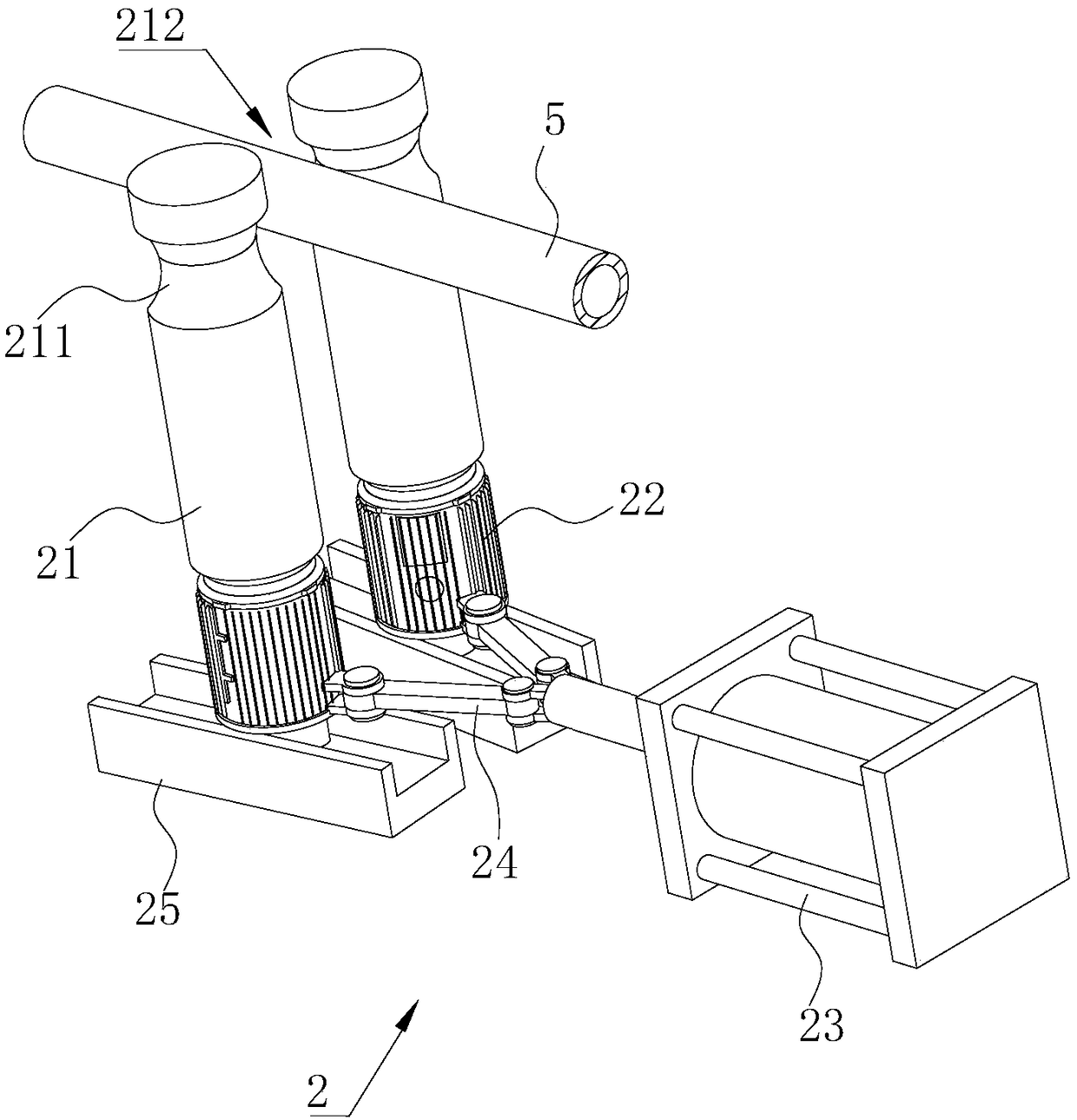

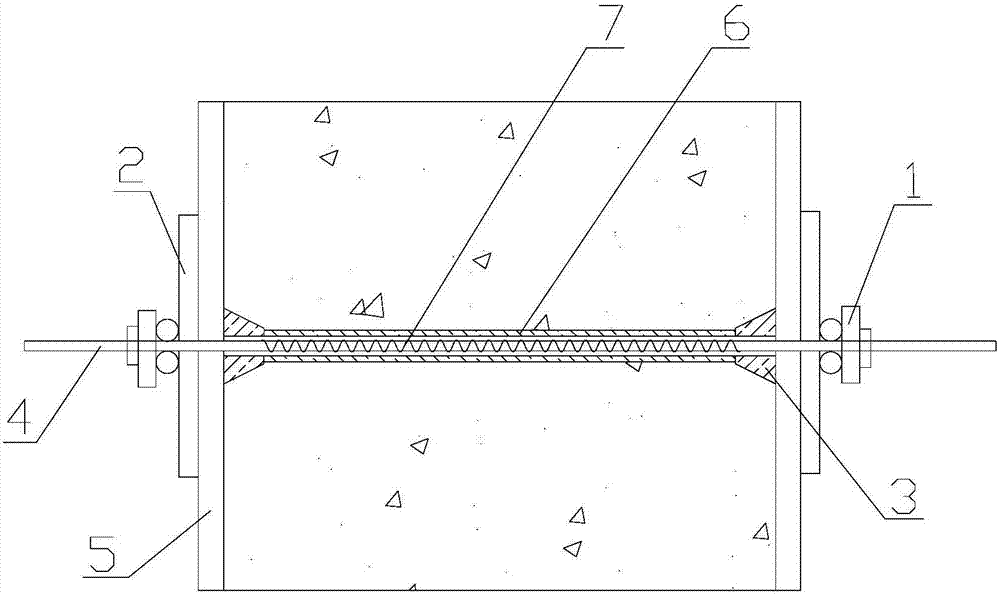

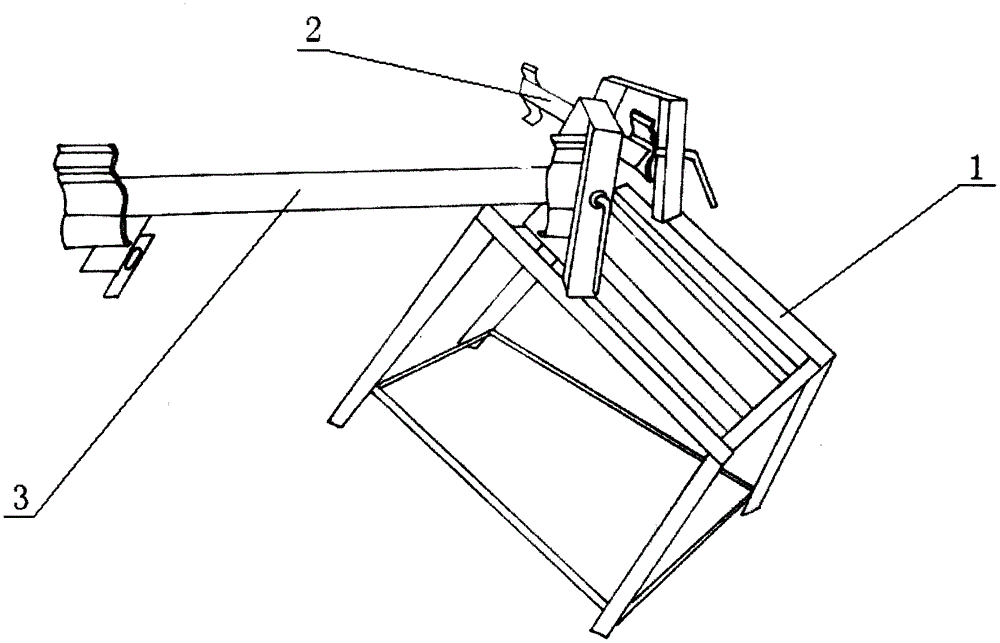

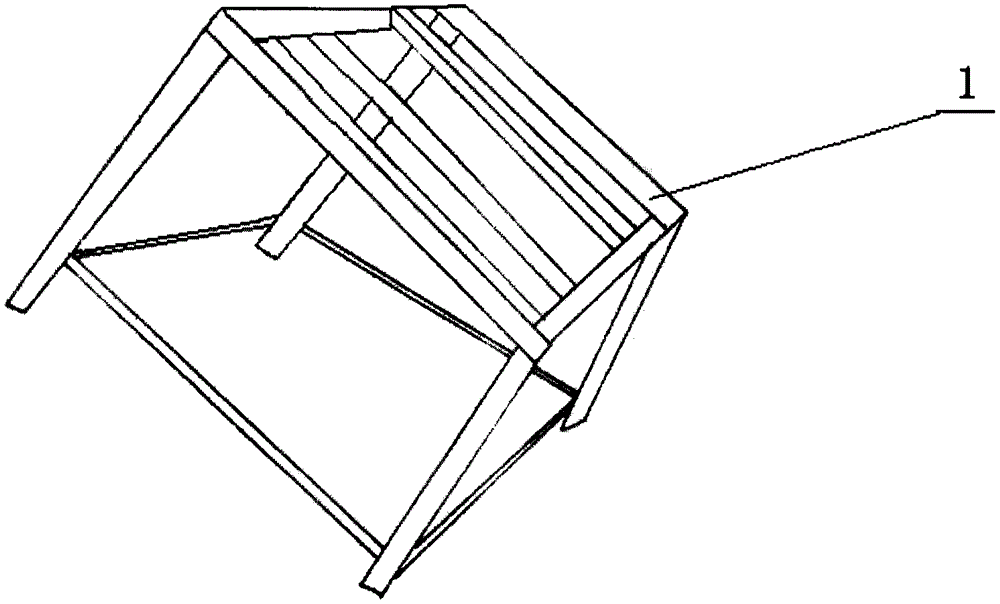

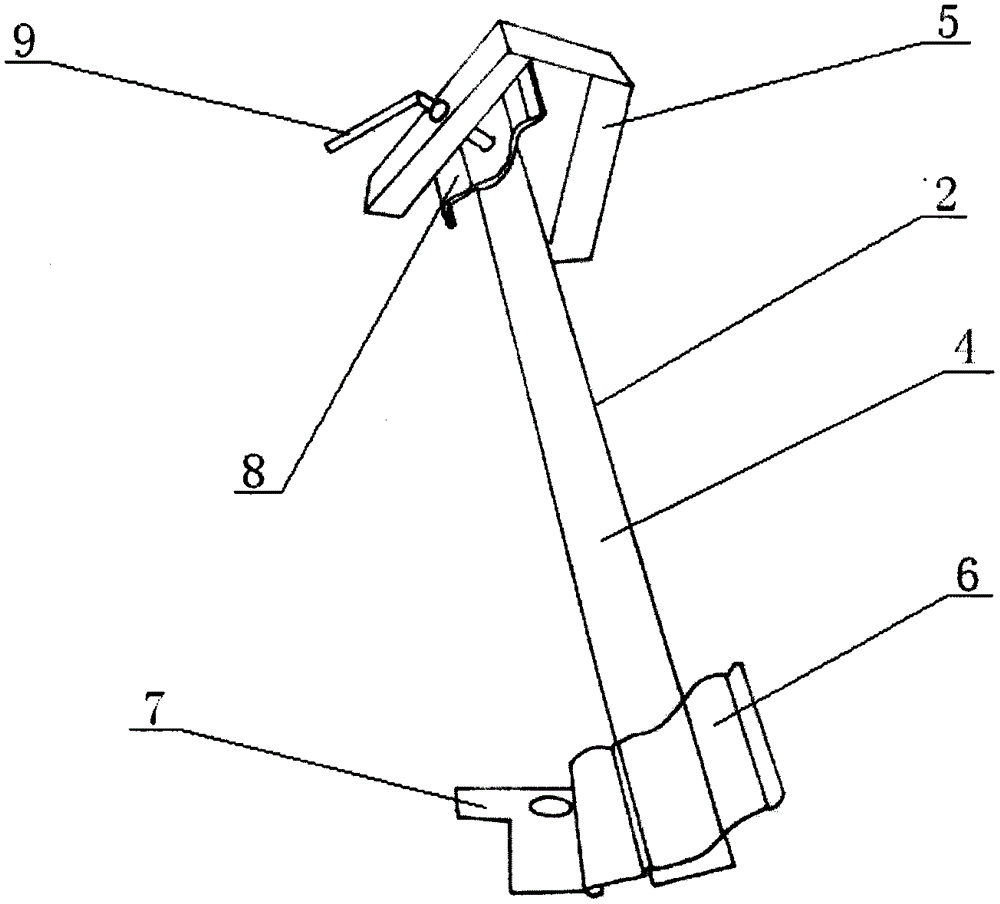

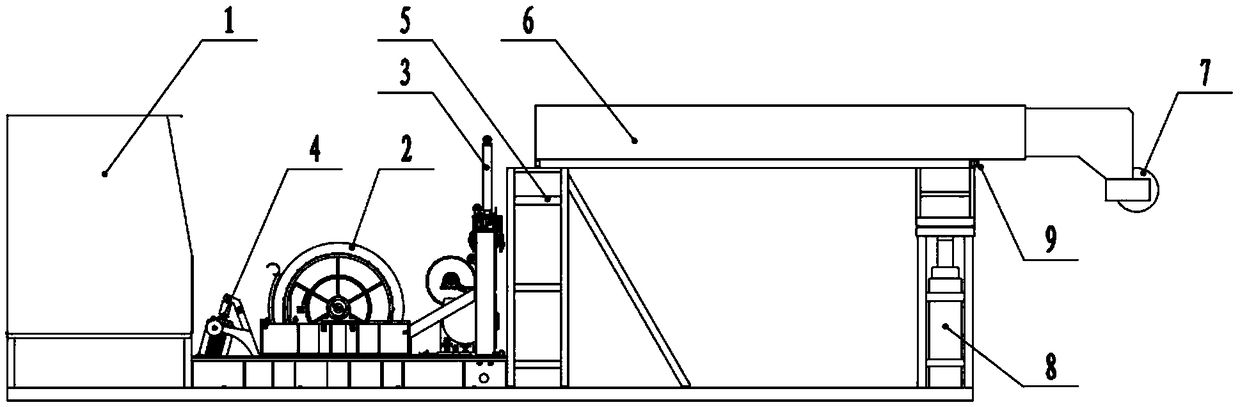

Pile head large-diameter steel bar straightening device

The invention discloses a pile head large-diameter steel bar straightening device, comprising a bracket, an elevating mechanism, a hydraulic straightening device and a hydraulic power and control system. The hydraulic straightening mechanism comprises a straightening frame, a movable compression bar, and a hydraulic cylinder mounted in the straightening frame, wherein the middle part of the straightening frame is provided with a straightened steel bar insertion hole which is a through hole from top to bottom, the movable compression bar is inserted into the straightened steel bar insertion hole, and the travel direction of a piston rod of the hydraulic cylinder is perpendicular to the straightened steel bar insertion hole. In the whole steel bar straightening process, except for a carrying instrument and an operating instrument, the rest parts of the pile head large-diameter steel bar straightening device are mechanically operated, so that the pile head large-diameter steel bar straightening device has high degree of mechanization and can greatly save labor force and improve work efficiency.

Owner:中建三局集团(深圳)有限公司 +1

A kind of preparation method of pumpkin nutrient fertilizer

InactiveCN102285832ALow growth needsMeet growth and development needsFertilizer mixturesBiotechnologyAdditive ingredient

A preparation method of pumpkin nutrient fertilizer, which is composed of: chicken manure powder, dried pig manure, wheat straw powder, sesame straw powder, sorghum powder, cottonseed cake powder, pea husk powder, rice husk powder, bran powder , sweet potato stem and leaf powder, cottonseed husk powder, compound fertilizer, bone meal, fig leaf powder, eggplant stem and leaf powder, brown sugar, safflower powder, poria powder, tea dry powder, Chuanwu powder, garlic powder, and the stated percentages are percentages by weight The nutrient fertilizer cultivated by the invention is cheap, the raw materials are easy to obtain, the preparation and preparation methods are simple, and the content of various nutrients in the ingredients is rich, which promotes the fast growth and development of pumpkins, strong growth, good disease prevention performance, and large pumpkins produced. Big and heavy.

Owner:梁春

Well head mobile anti-theft device

InactiveCN101666219AConvenient for daily managementSimple processWell/borehole valve arrangementsSealing/packingEngineeringOil production

The invention relates to a well head mobile anti-theft device mainly comprising parts, i.e. a conical seat type oil pipe hanger, a bottom ring flange, a well head large cross joint, an upper ring flange, a small tee joint, anti-theft strobes (i.e. a casing strobe and a production control strobe), a needle-shaped control valve, and the like, wherein the parts, i.e. the conical seat type oil pipe hanger, the bottom ring flange, the well head large cross joint, the upper ring flange, the small tee joint, and the like, are completely matched with parts a 250-type christmas tree generally used foran oil field. The anti-theft technique is used for the production management control function of a well head, thus the product has incomparable advantages compared with other similar products; the casing strobe and the production control strobe are manufactured by adopting the anti-theft technique; four sluice valves used in the oil production well head are all anti-theft sluice valves manufactured by the company and adopt two-stage anti-theft measures and omit hand wheels on appearance compared with the traditional 250-type strobe, the internal structures of the sluice valves can not be seenfrom external, and the anti-theft strobes can be opened only after an anti-theft cover is opened by a special spanner.

Owner:彭仔强 +1

Sea tidal fall water pumping device

ActiveCN103388567AChange the form of power generationImprove the environmentPiston pumpsPositive-displacement liquid enginesEngineeringSea level

The invention discloses a sea tidal fall water pumping device comprising a fixing water cylinder, a float assembly capable of vertically moving and a water pipe; the float assembly is positioned above the fixing water cylinder, and is provided with a hollow floatation box; during ebb tide, the hollow cavity of the floatation box has sea water for increasing the weight of the floatation box; during ebb tide, the lower part of the float assembly is sealed with the upper part of the fixing water cylinder; one end of the water pipe is communicated with the lower part of the fixing water cylinder; and the other end of the water pipe extends out of sea level. The sea tidal fall water pumping device adopting such a structure can convey sea water to the position higher than the sea level without adopting external power, can overcome the multiple defects of the tidal power generation in the prior art, can change the low-water head large-flow power generation mode in the prior art, and can improve the environment of construction and foundation processing of the existing power generation station and the slit-prevention engineering project, thus reducing power generation investment, reducing power generation operation cost and achieving cleanliness and environment friendliness.

Owner:马灼明

Formwork connecting piece

InactiveCN106121229APrevent fallingConvenient statisticsAuxillary members of forms/shuttering/falseworksEngineeringSingle strand

The invention provides a formwork connecting piece. The formwork connecting piece comprises a pin dowel, a pin piece and a connecting rope connected with the pin dowel and the pin piece. The pin dowel comprises a conical pin dowel body and a dowel cap fixedly welded to the big end of the dowel pin body. A pin piece hole is formed in the dowel pin body, and one side face of the dowel cap is provided with a protrusion. Compared with the prior art, the formwork connecting piece has the beneficial effects that firstly, the dowel cap is additionally provided with the protrusion based on an original pin dowel, and thus the field construction efficiency is improved; and secondly, connection holes are formed in the protruding dowel cap of the pin dowel and the pin piece, and a single-strand steel wire is used for series connection. Original two independent articles are combined to form a set according to actual requirements, so that the pin piece is prevented from falling in the insertion process, and quantity statistics is convenient; and field construction and material management are greatly facilitated, material waste is reduced, and cost is reduced.

Owner:SNTO TECH GRP

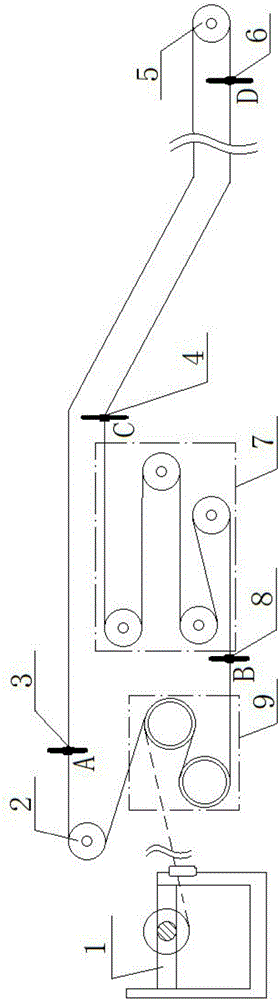

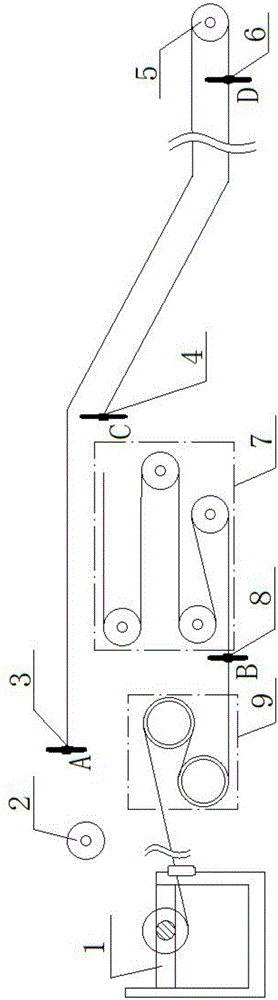

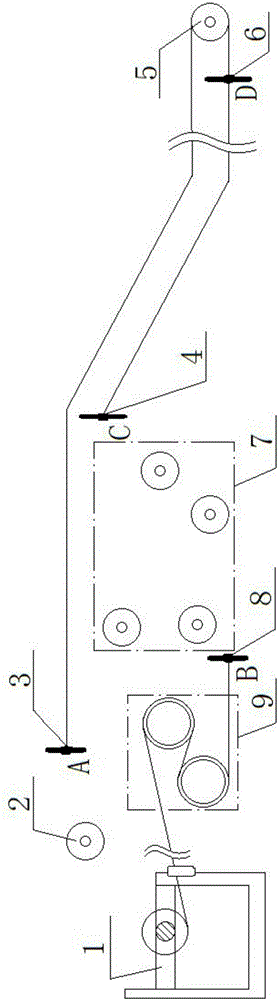

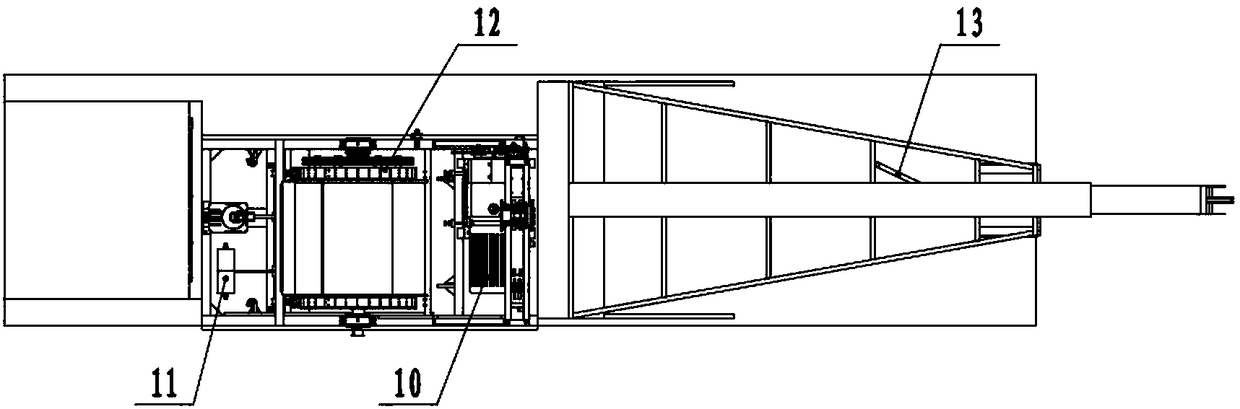

Rapid retraction method for belt conveyer and tape handler for retraction

The invention provides a rapid retraction method for a belt conveyer and a tape handler for retraction, and belongs to the technical field of underground coal mine fully-mechanized excavation face belt conveyers. The problems that a traditional belt demounting process mainly depends on manual operation, so that the labor intensity is large, the retraction time is long, and the work efficiency is low are mainly solved. The rapid retraction method includes the steps of selecting subsection cut-off points or butt joint points, cutting off a belt, tape winding and recovering a belt piece. The rapid retraction method is characterized by comprising the following specific steps: (1) selecting the subsection cut-off points or the butt joint points; (2) cutting off the belt at the cut-off points; (3) retracting AC belt sections at the lower portions; (4) retracting AD belt sections, and meanwhile recovering an upper carrier roller; (5) retracting CD belt sections, and meanwhile recovering the belt piece; and (6) retracting a driving part and a belt conveyor head large frame after retraction of all belts is finished, and retracting the tape handler. The tape handler for retraction comprises a power device, a tape winding shaft and a machine frame. The tape handler is characterized by further comprising filter belt centering devices symmetrically arranged on stand columns of the machine frame.

Owner:CHINACOAL PINGSHUO GRP

Intelligent tension tool anchor capable of making penetration of prestressed reinforcing steel easy

PendingCN108457197AEasy to pullEasy to wearBridge erection/assemblyBuilding material handlingPre stressEngineering

Owner:重庆恒佳工程技术咨询有限公司

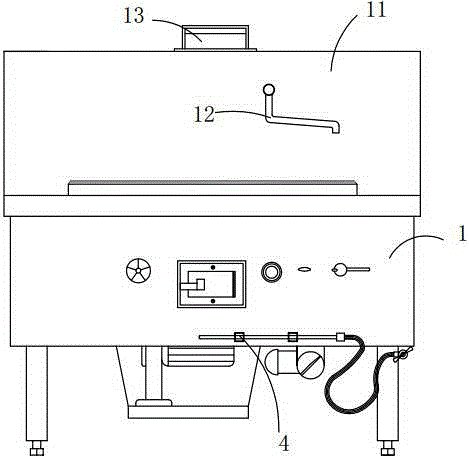

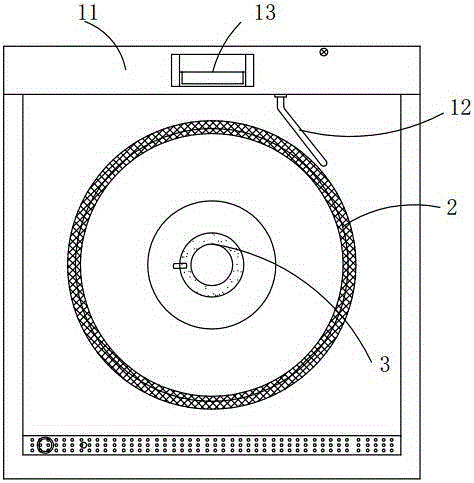

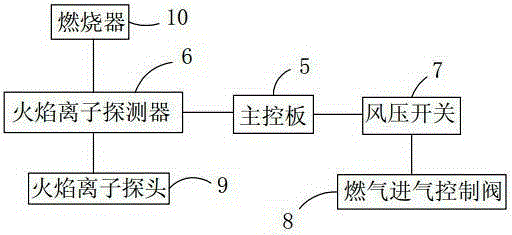

Gas single-head large pot stove

InactiveCN105351977AWon't leakShorten the timeDomestic stoves or rangesLighting and heating apparatusSafety controlEngineering

The invention discloses a gas single-head large pot stove which comprises a stove frame as well as a fender, a stove head and an ignition extinguishment safety control device which are arranged on the stove frame, and is characterized in that the ignition extinguishment safety control device comprises a main control panel as well as a flame ion detector and a wind pressure switch which are connected with the main control panel; the wind pressure switch is connected with a gas inlet control valve; and the flame ion detector comprises a flame ion detection head which is arranged above a combustor of the stove head as the anode of an electric field, and the combustor used as the cathode of the electric field. According to the gas single-head large pot stove, the ignition and extinguishment processes are monitored through the flame ion detector, the flame ion detector detects whether flames exist or not within one second, and directly transmits the signal to the main control panel, the main control panel sends an instruction according to the signal, and the gas inlet control valve is opened or closed; the whole action is within five seconds, the time is short, the response is rapid, the leakage of a lot of gas is avoided, and the stove is safe and reliable.

Owner:重庆金田厨具工程有限公司

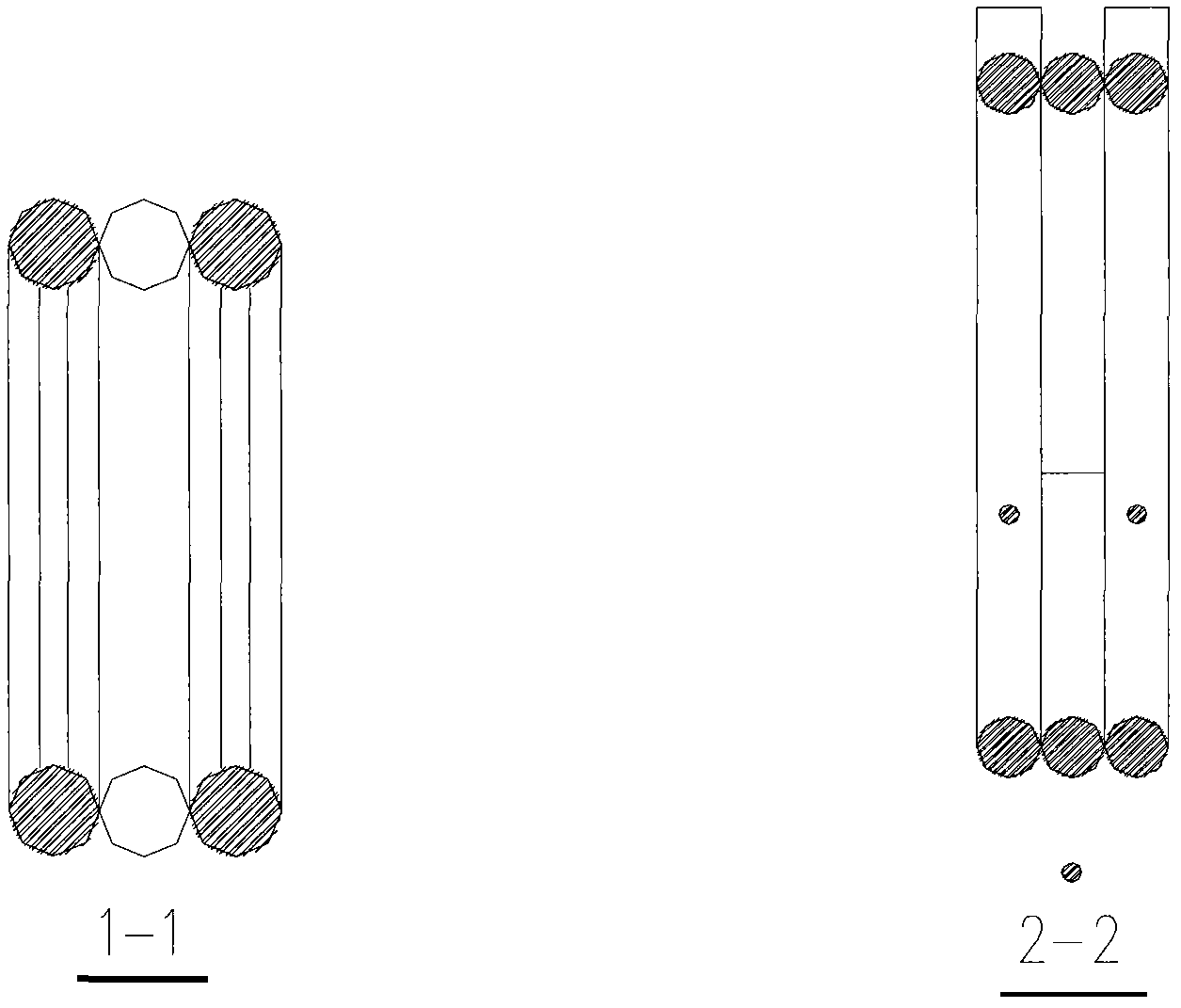

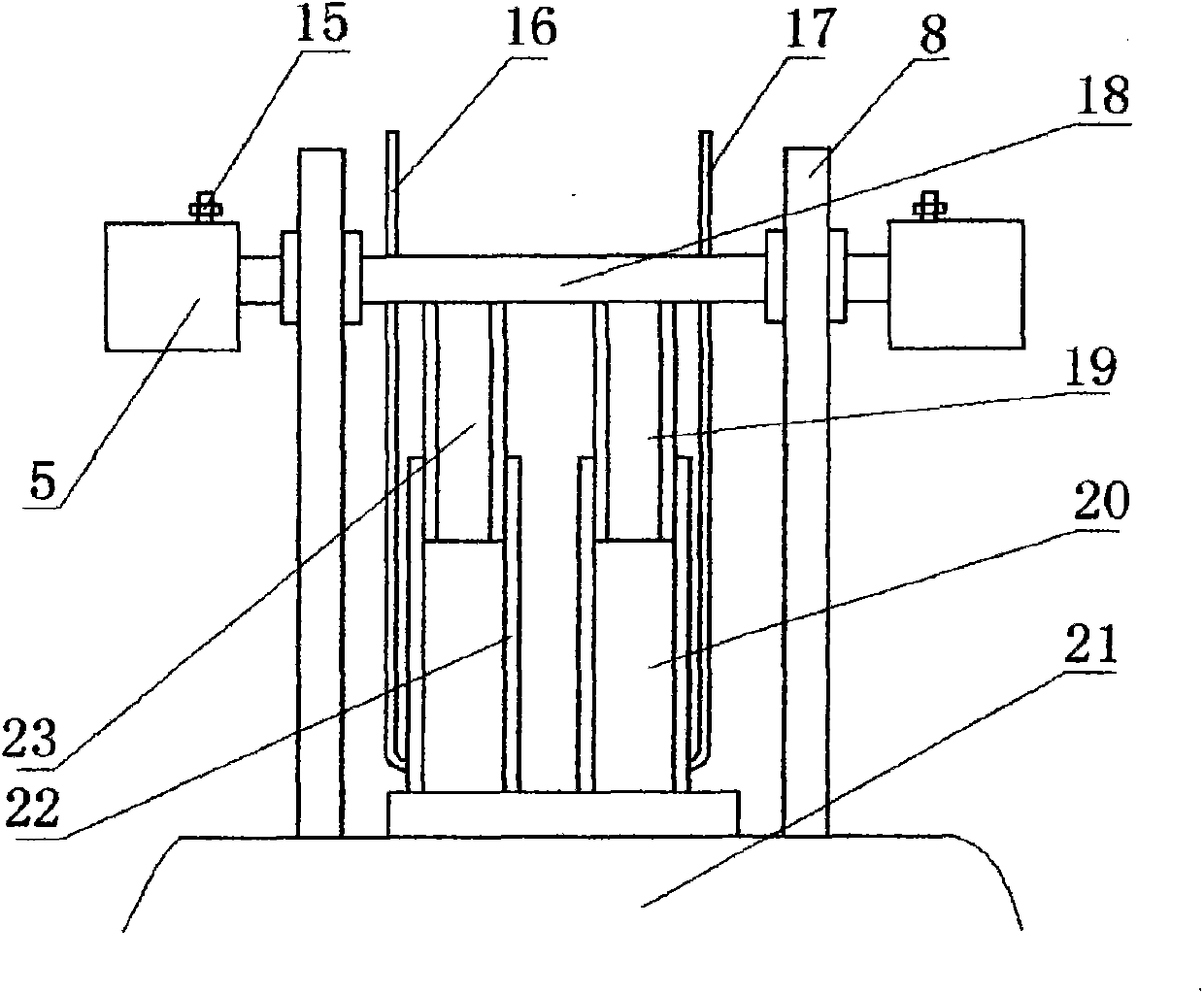

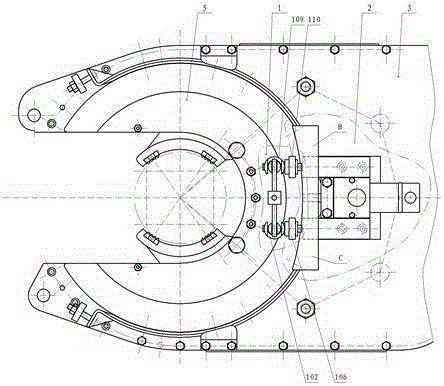

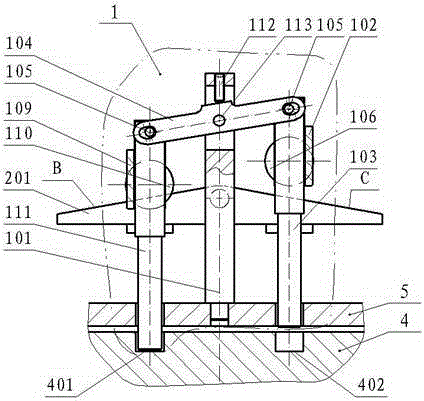

Ring-removing mechanism for single-head large-cylinder-diameter nodular cast iron piston ring

InactiveCN104923770AThe overall structure is simple and reliableReliable completionPiston ringEngineering

The invention discloses a ring-removing mechanism for a single-head large-cylinder-diameter nodular cast iron piston ring, and belongs to the technical field of piston ring machining. A workbench is vertically provided with at least three supporting rods in a fixed manner, and the supporting rods support one horizontal cover plate. The center of the cover plate is connected with a telescoping rod which passes through a vertical impact cylinder in a central hole of the cover plate. An inner side of a space formed by the enclosing of the supporting rods is provided with a rear baffle plate in a vertical manner. The workbench is also fixedly provided with a horizontal clamping cylinder, and the tail end of the telescoping rod is fixedly connected with a front baffle plate. When the horizontal clamping cylinder shrinks, the front baffle plate and the rear baffle plate surround a piston ring blank disposed between the front and rear baffle plates. The mechanism provided by the invention can enable the ring removal of the single-head large-cylinder-diameter nodular cast iron piston ring to be completed conveniently and reliably, reduces the rejection rate, and reduces the labor intensity of workers.

Owner:ASIMCO SHUANGHUAN PISTON RING YIZHENG

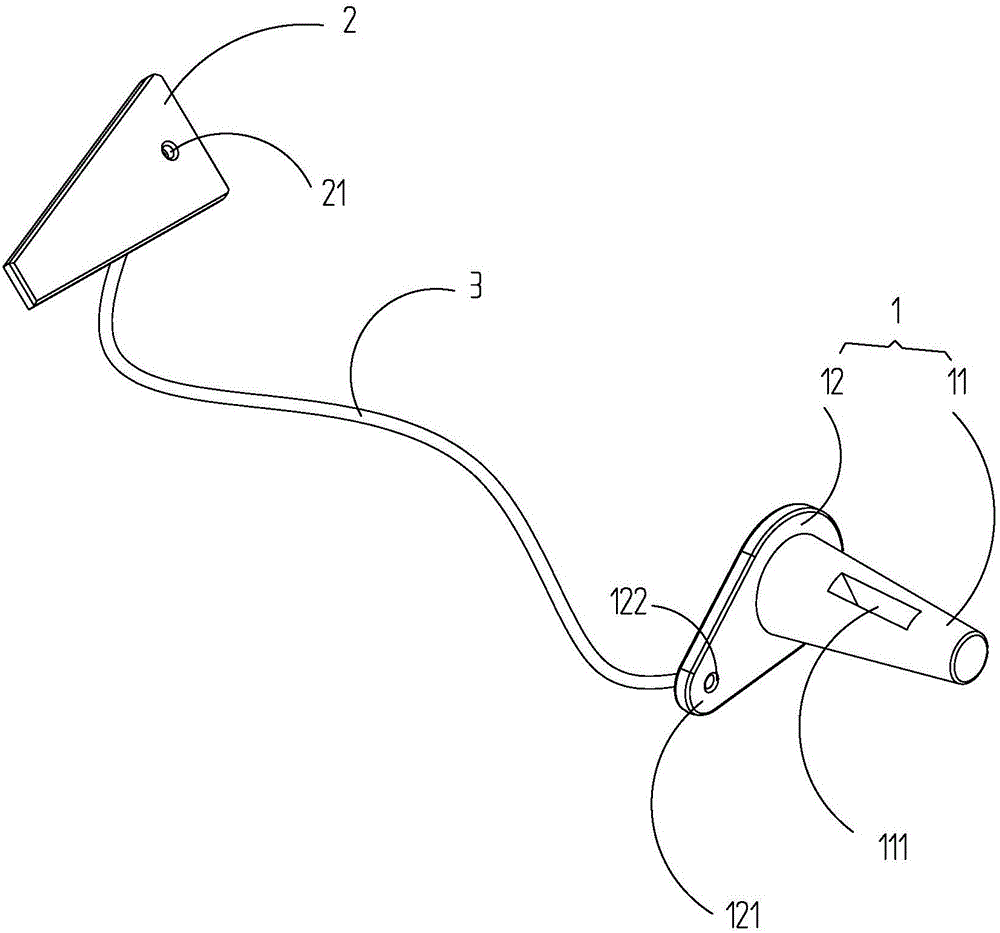

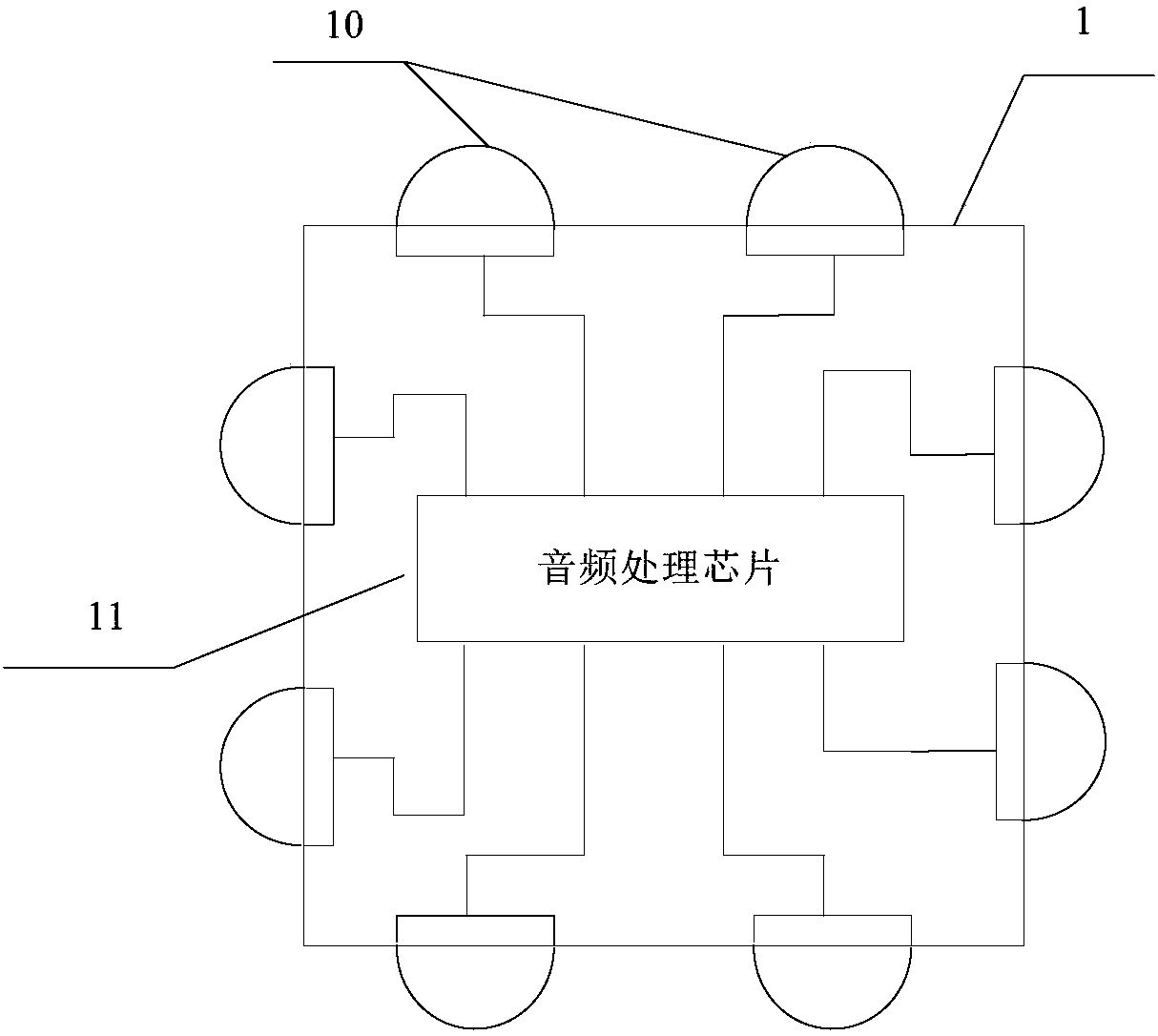

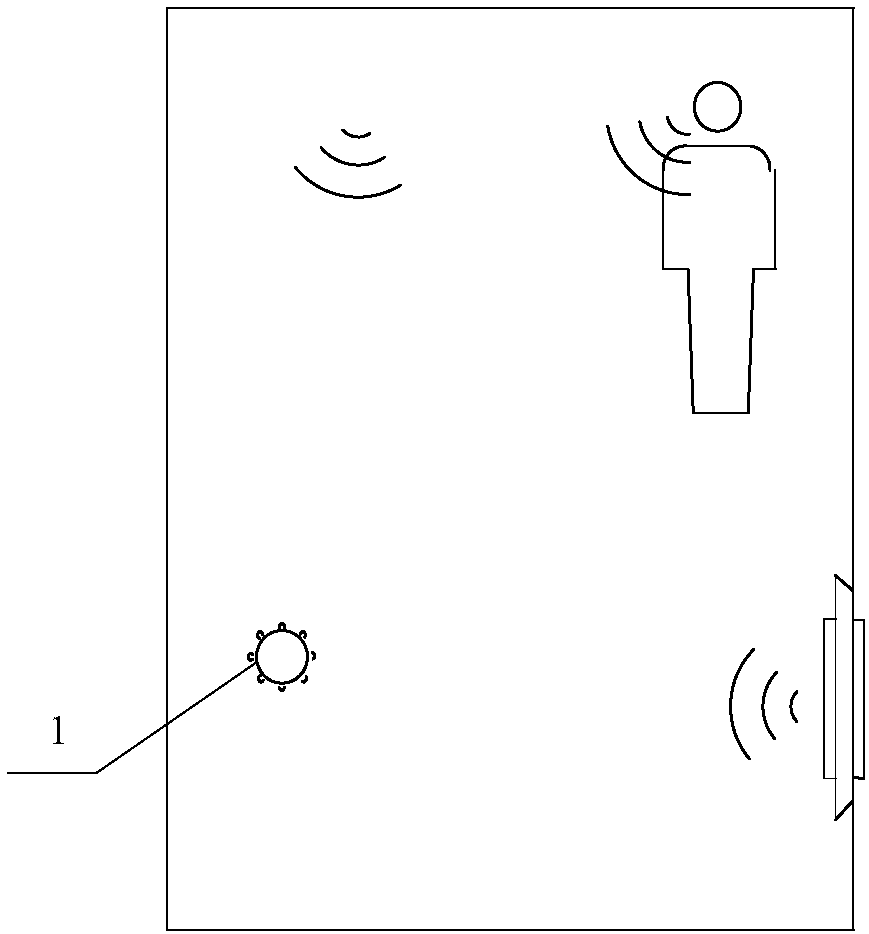

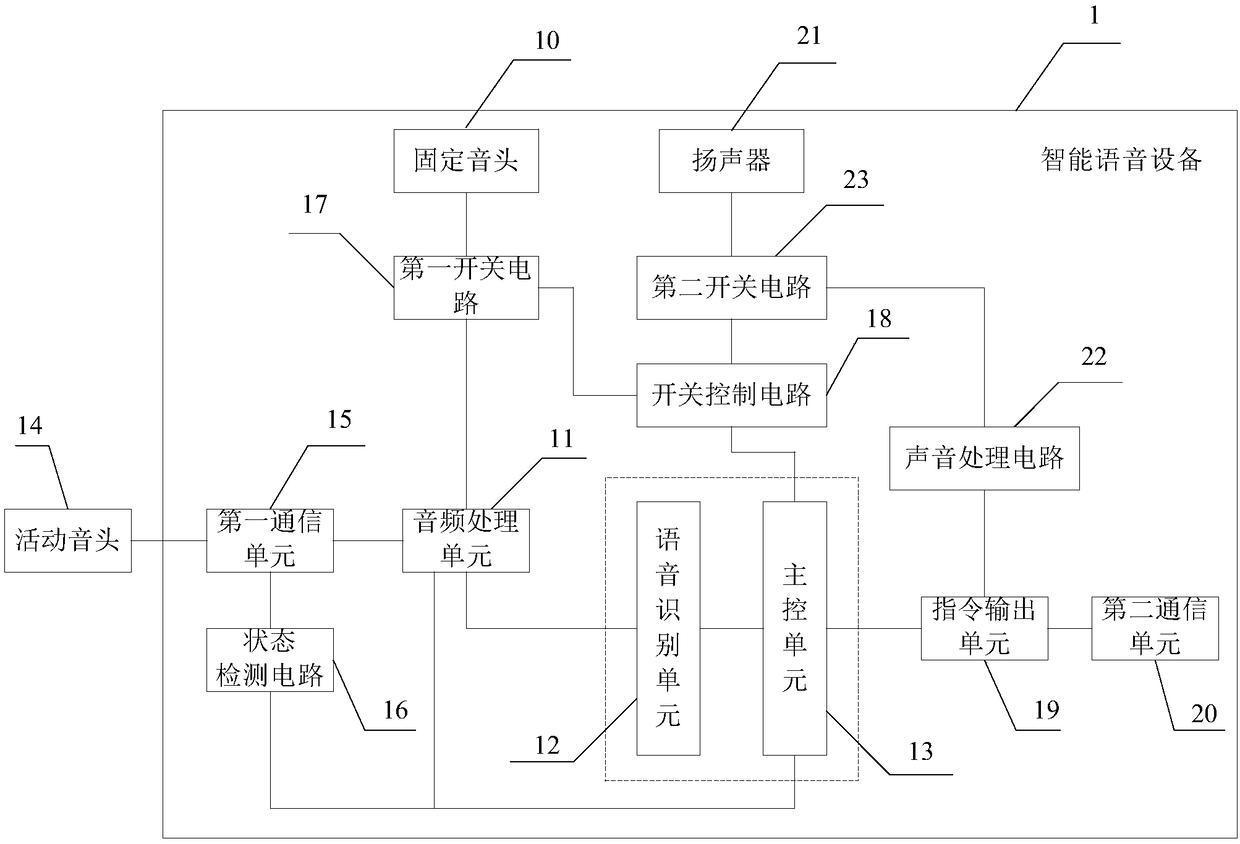

Intelligent voice device and control method thereof

ActiveCN109473096AImprove reliabilityGuaranteed accuracySpeech recognitionSpeech identificationSpeech sound

The embodiment of the invention discloses an intelligent voice device and a control method thereof. The intelligent voice device comprises a fixed voice head and at least one movable voice head whichcan be combined with or disengaged from the intelligent voice device on the physical structure. The method includes the steps of generating a first instruction signal which makes the signal-noise ratio of voice signals picked by the movable voice heads larger than or equal to a first threshold when the movable voice heads are in an instruction input state, judging whether the signal-noise ratio ofthe voice signals picked by the movable voice heads is larger than or equal to the first threshold or not according to the first instruction signal, if yes, executing the last step, if not, executingthe next step, conducting denoising treatment on the voice signals picked by the movable voice heads so that the signal-noise ratio can be larger than or equal to the first threshold, and conductingvoice recognition on the voice signals with the signal-noise ratio larger than or equal to the first threshold. By means of the intelligent voice device, near-distance voice picking can be conducted through the movable voice heads, the voice recognition accuracy can be effectively ensured, and the intelligent voice device is simple in operation and convenient to use.

Owner:BEIJING JUNLIN TECH CO LTD

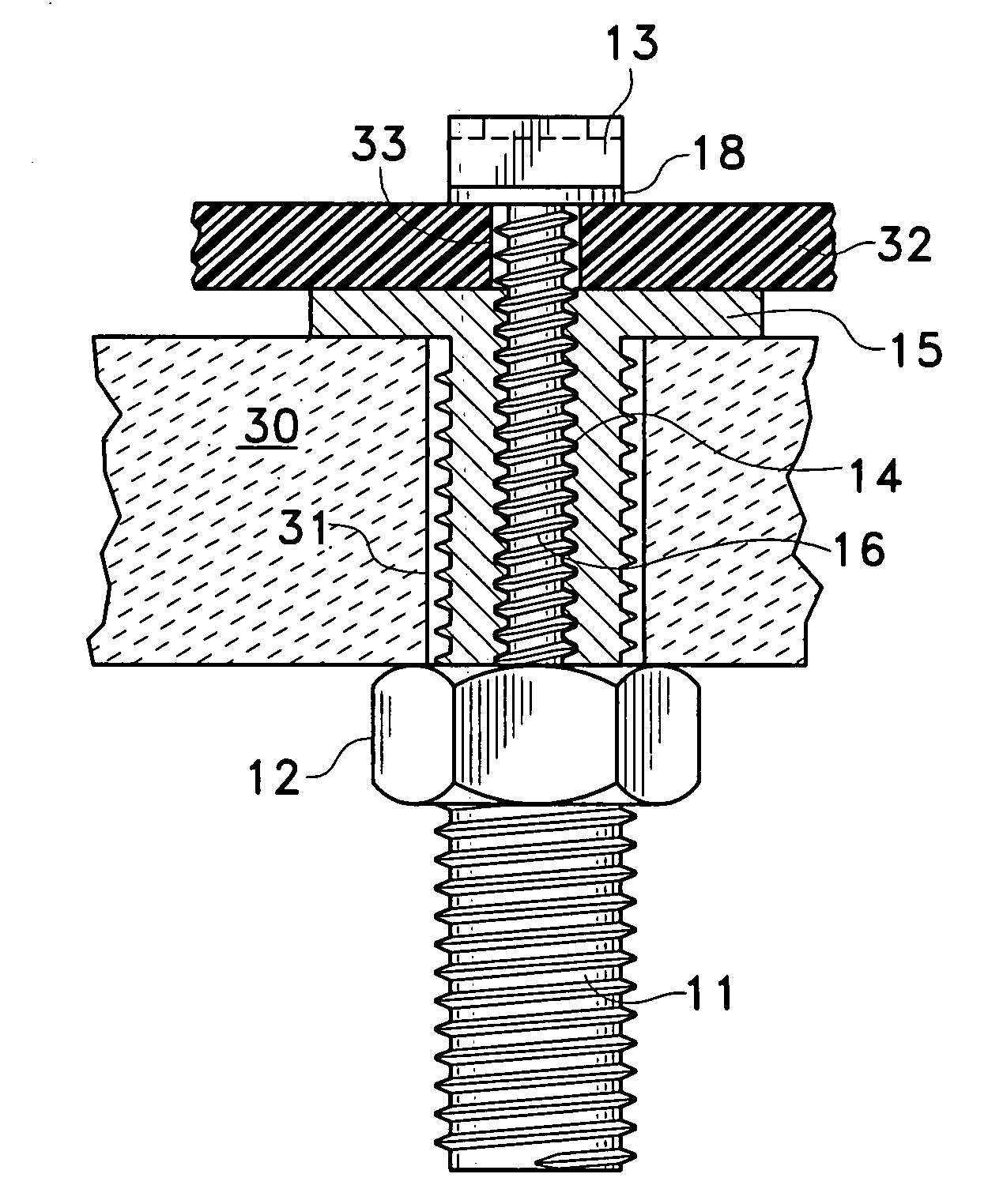

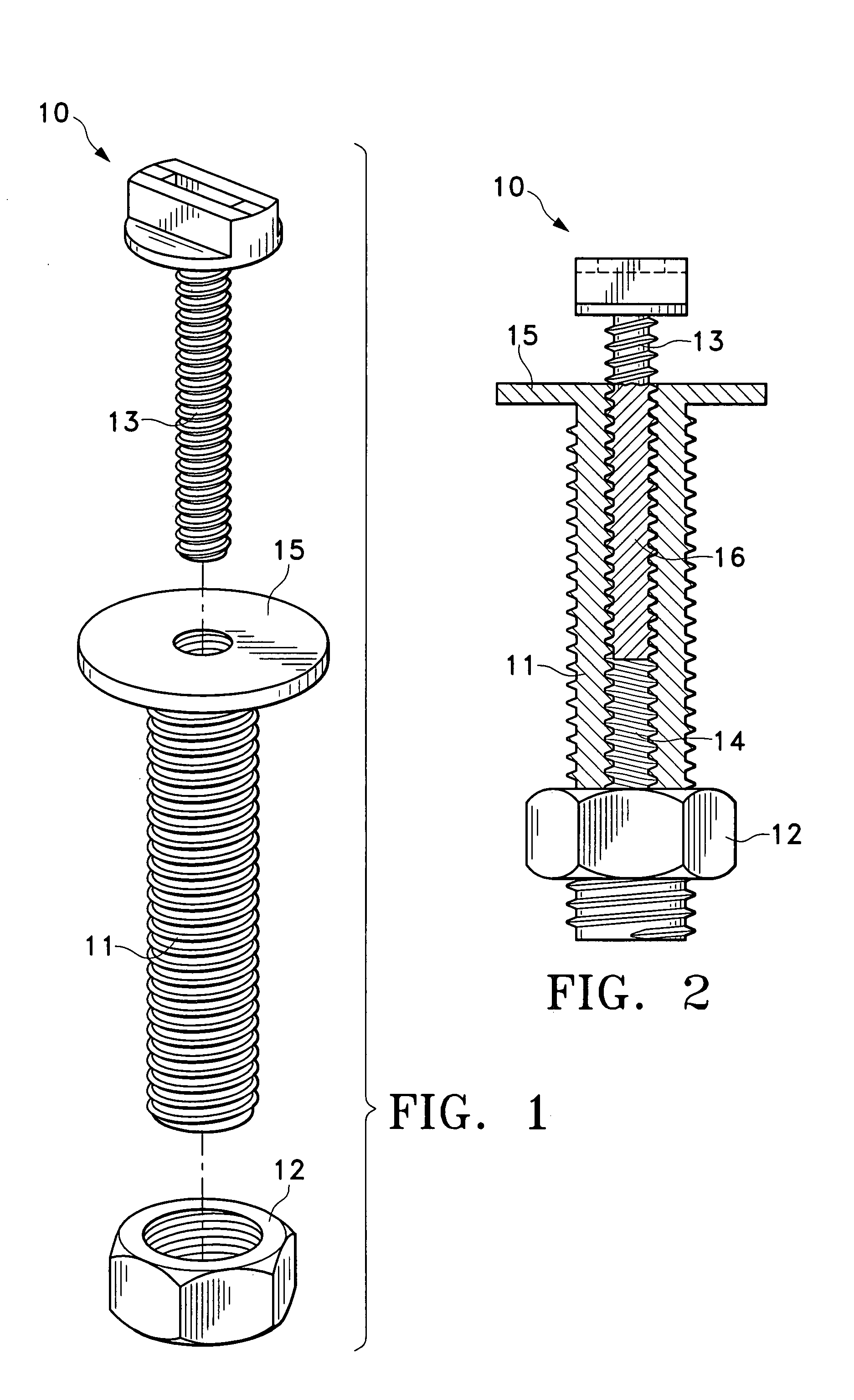

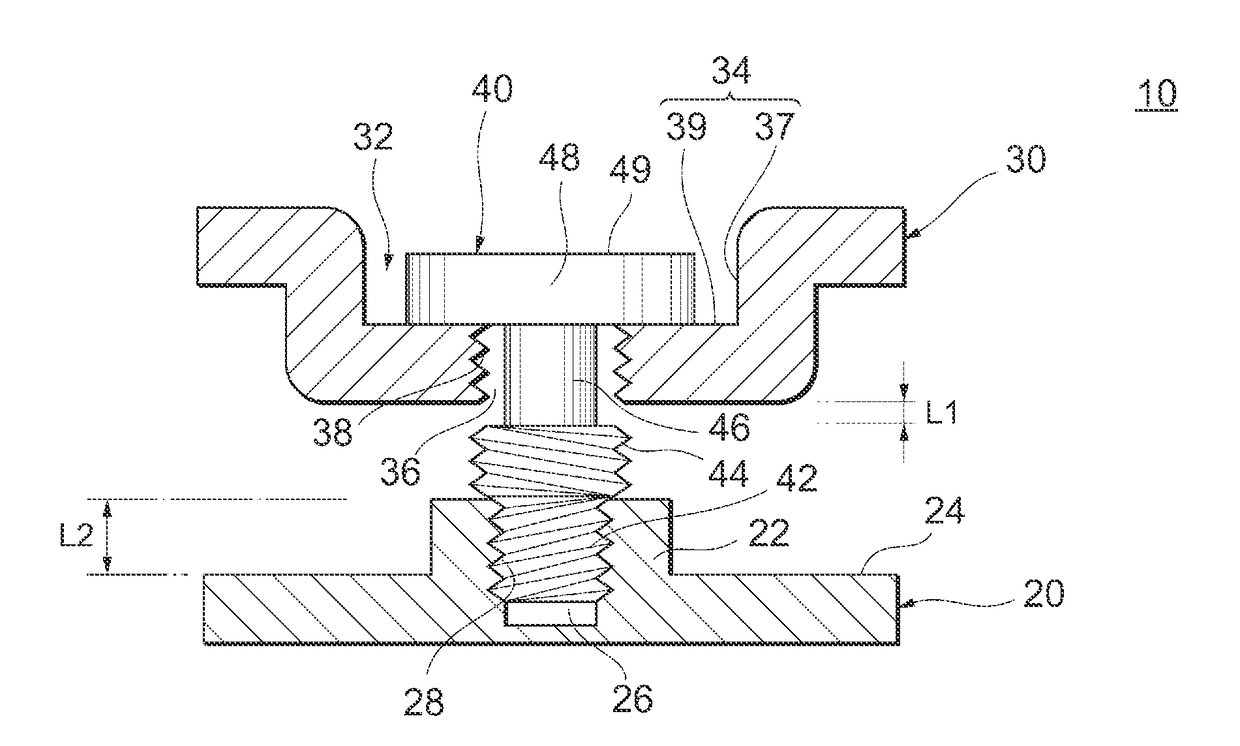

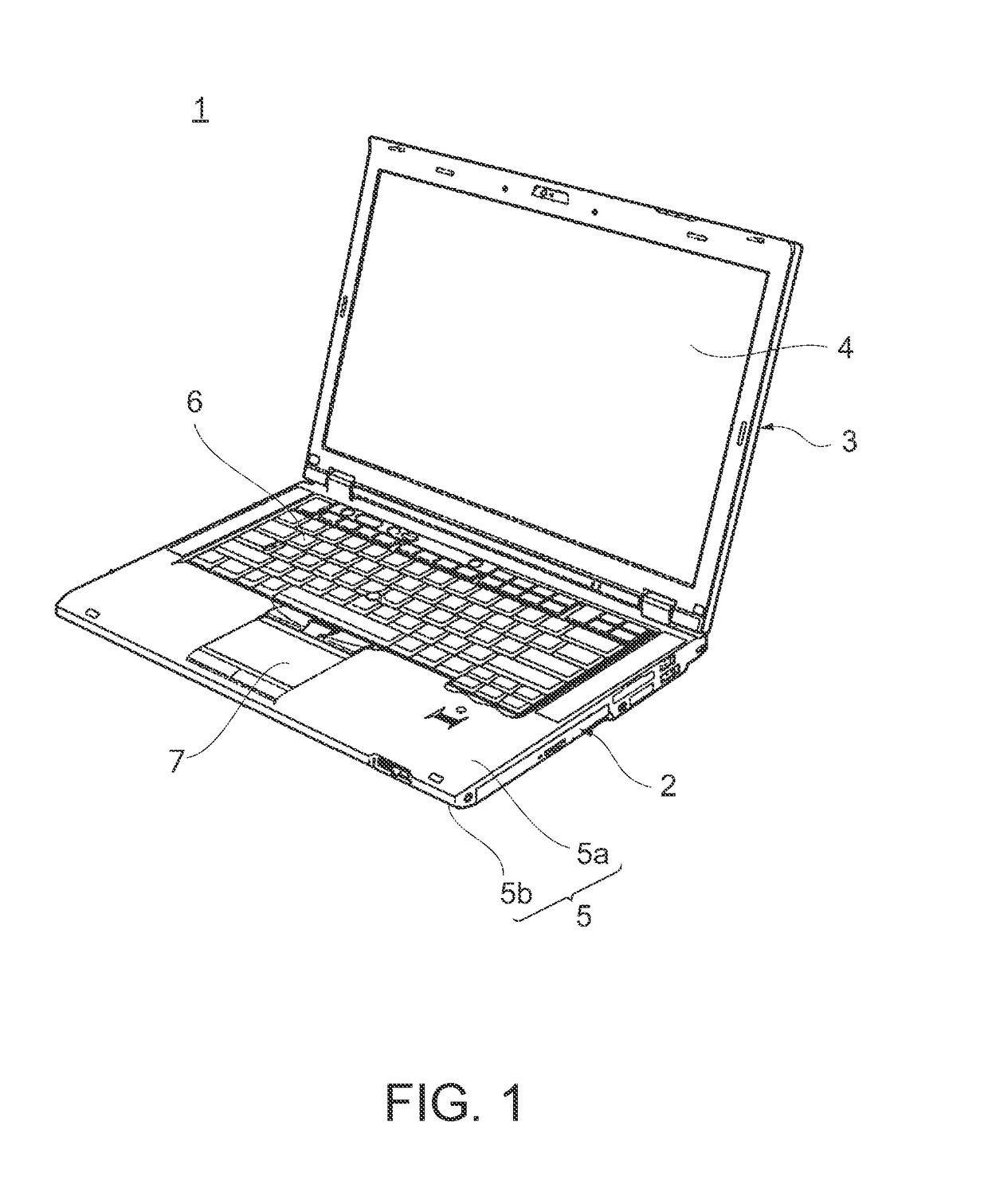

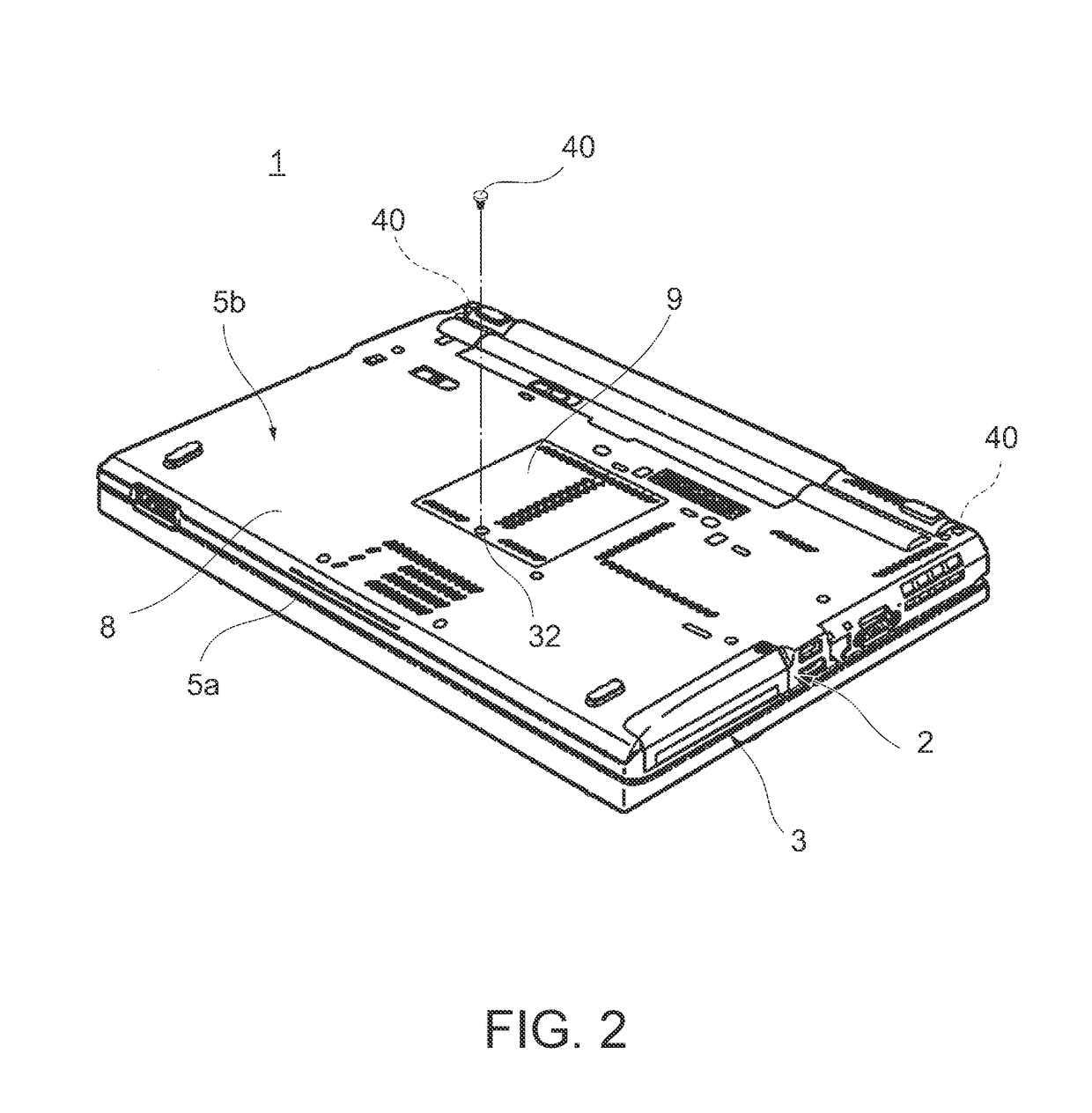

Structure, manufacturing method therefor, and fastener

The present invention provides a structure for omitting washers to reduce the number of parts, and keeping the fitting of two members fastened together even when the washers are omitted. The structure includes: a first member having a first screw hole; a second member facing the first member, having a second screw hole larger than the first screw hole, and threaded in a direction opposite to the first screw hole; and a fastener. The fastener includes, along a longitudinal direction: a first screw section having a diameter corresponding to the first screw hole; a second screw section between the first member and the second member, having a diameter corresponding to the second screw hole, and threaded in a direction opposite to the first screw section; a neck at least partially located in the second screw hole; and a head larger in the longitudinal direction than the second screw hole.

Owner:LENOVO PC INT

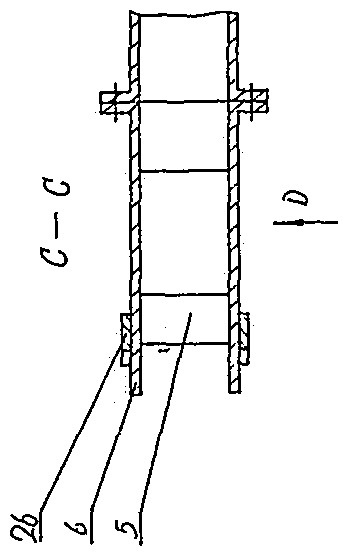

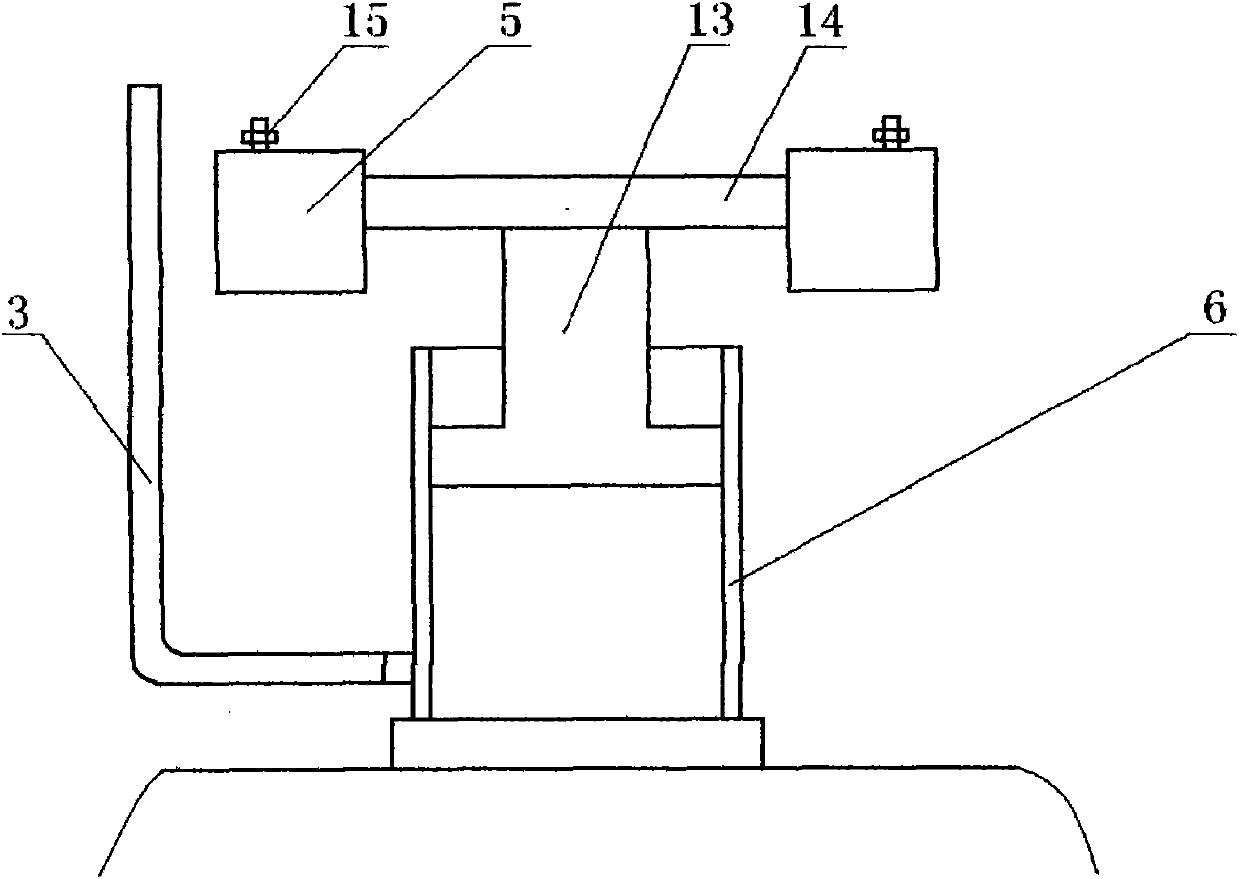

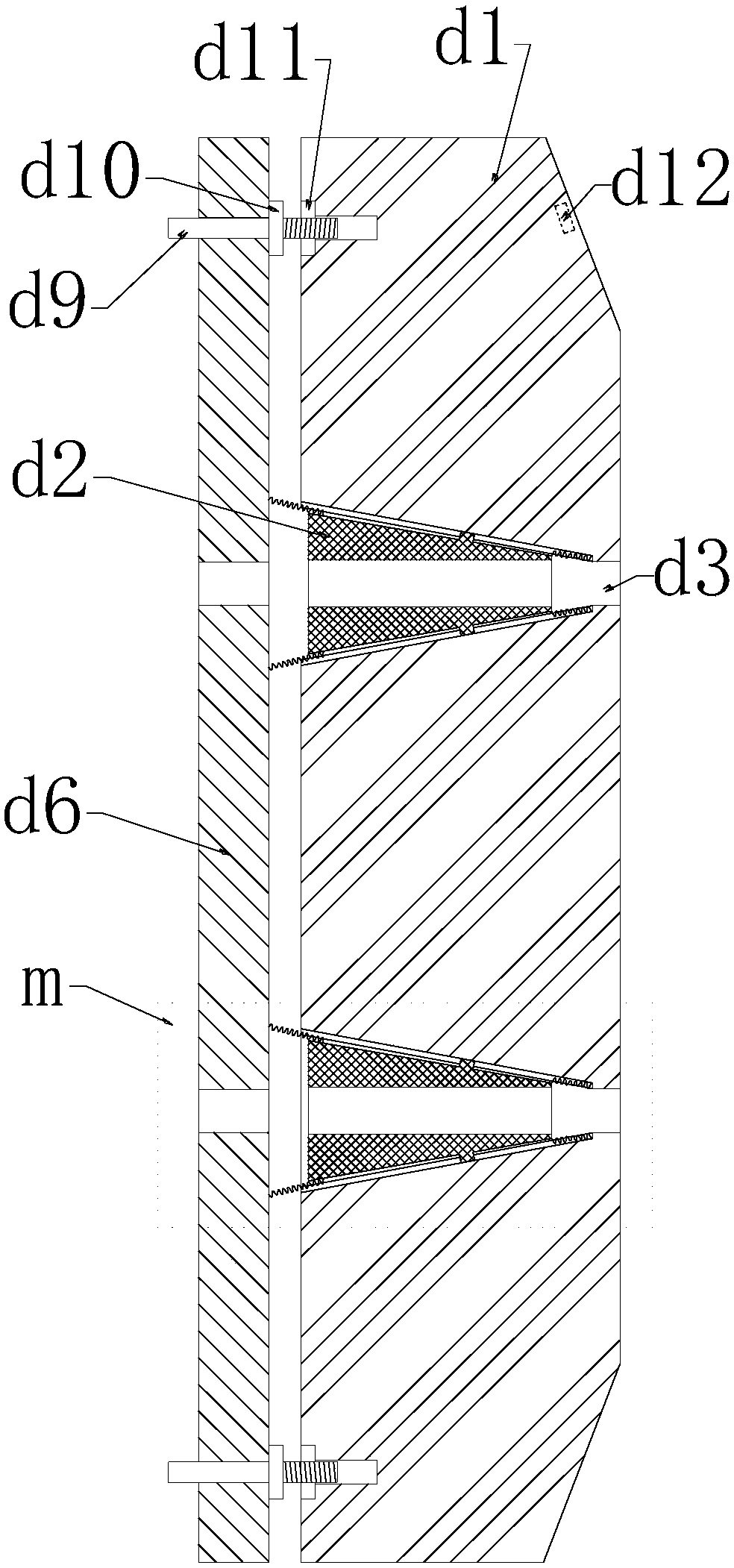

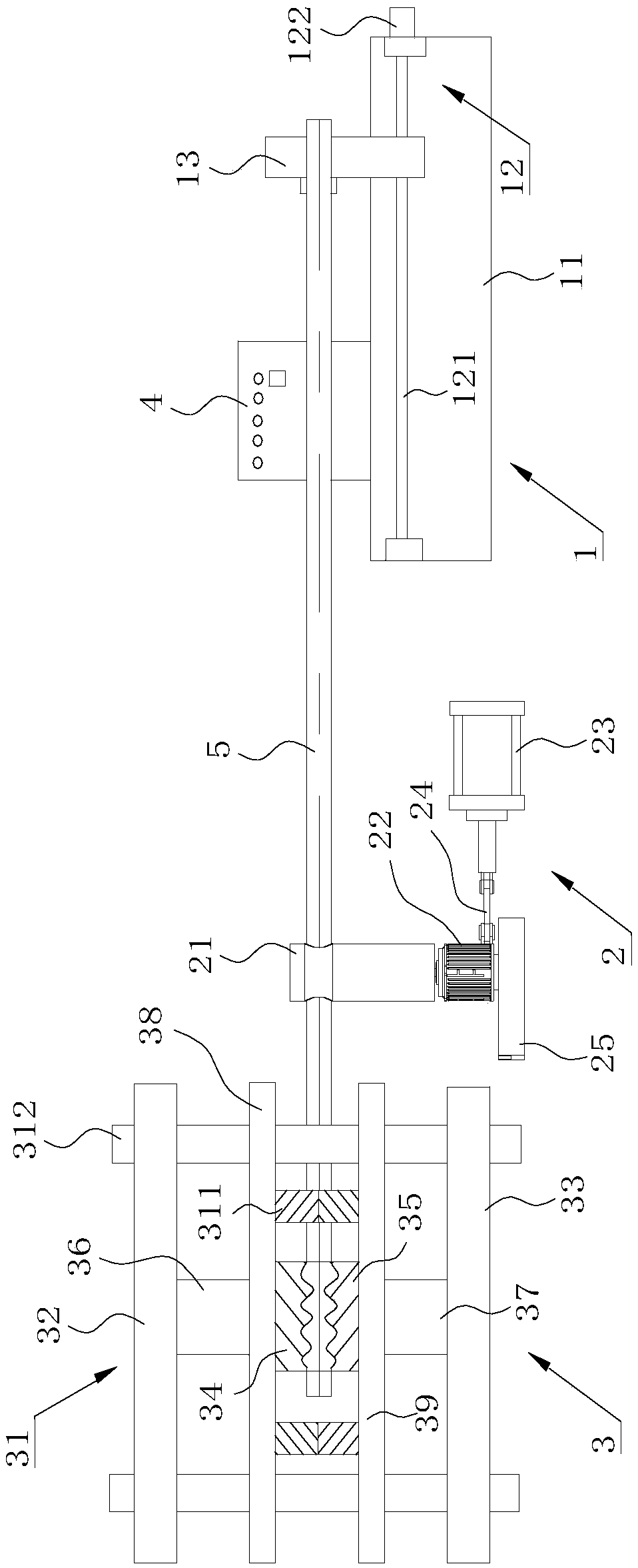

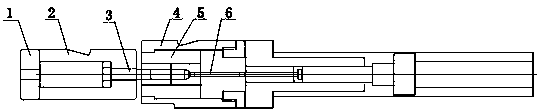

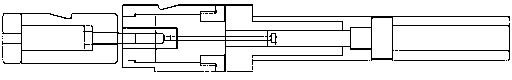

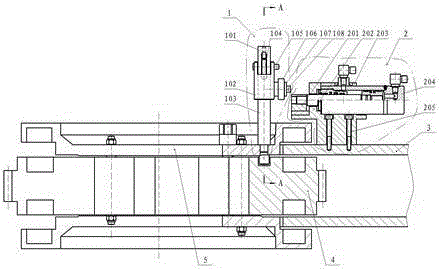

Multi-head large-displacement equal-wall-thickness screw pump stator production forming equipment and forming process thereof

ActiveCN108787868AAvoid bendingGuaranteed straightnessMetal-working feeding devicesPositioning devicesControl systemEngineering

The invention relates to the technical field of oil extraction, in particular to multi-head large-displacement equal-wall-thickness screw pump stator production forming equipment and a forming processthereof, and aims to shorten the stator machining process and improve the stator machining precision. The equipment mainly comprises a main feeding mechanism, a forming mechanism, and an auxiliary feeding mechanism positioned between the main feeding mechanism and the forming mechanism; the main feeding mechanism comprises a hydraulic clamping and feeding fixture, and a driving part for driving the hydraulic clamping and feeding fixture to move; the forming mechanism comprises a hydraulic forming machine; the hydraulic forming machine, the hydraulic clamping and feeding fixture and the driving part are controlled through a digital combined adjusting device; and the digital combined adjusting device is a PLC control system. A pipe forming mold and related parts are mounted on the hydraulicforming machine to form a special hydraulic forming machine tool and a hydraulic clamping and feeding mechanism; and the digital combined adjusting device is used for controlling the whole machiningflow, so that the size precision and the straightness of machined stator pipes are improved, and qualified stator pipes are machined.

Owner:WUHAN HENGXINTAI OIL EQUIP MFG CO LTD

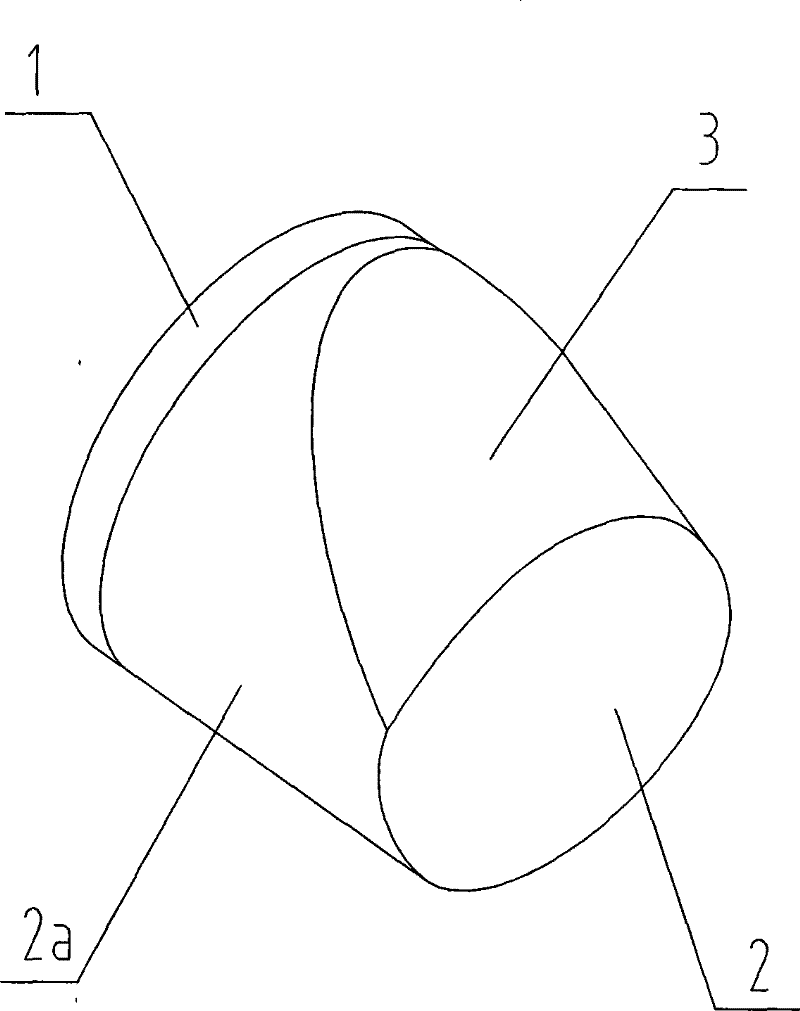

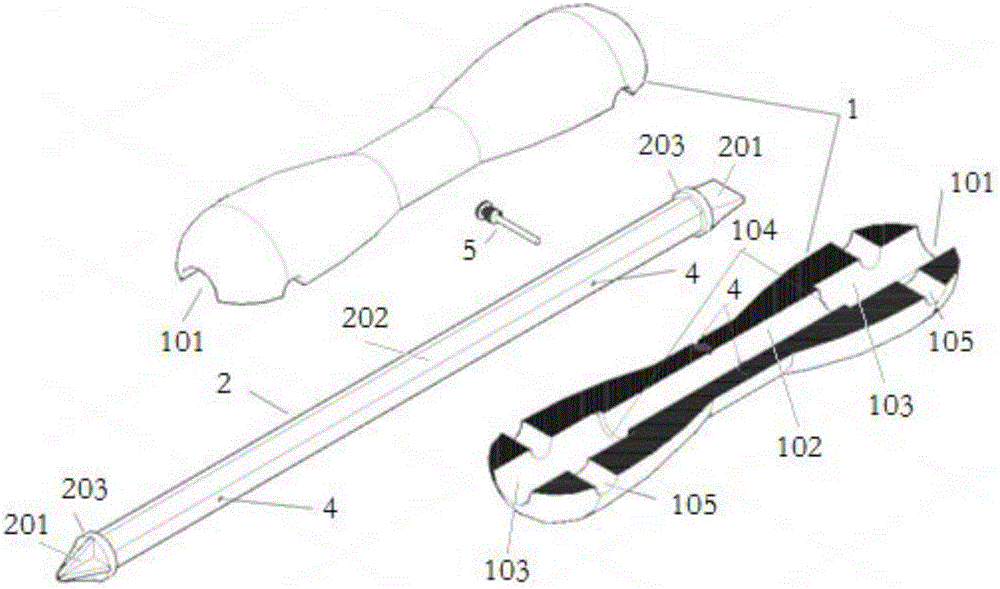

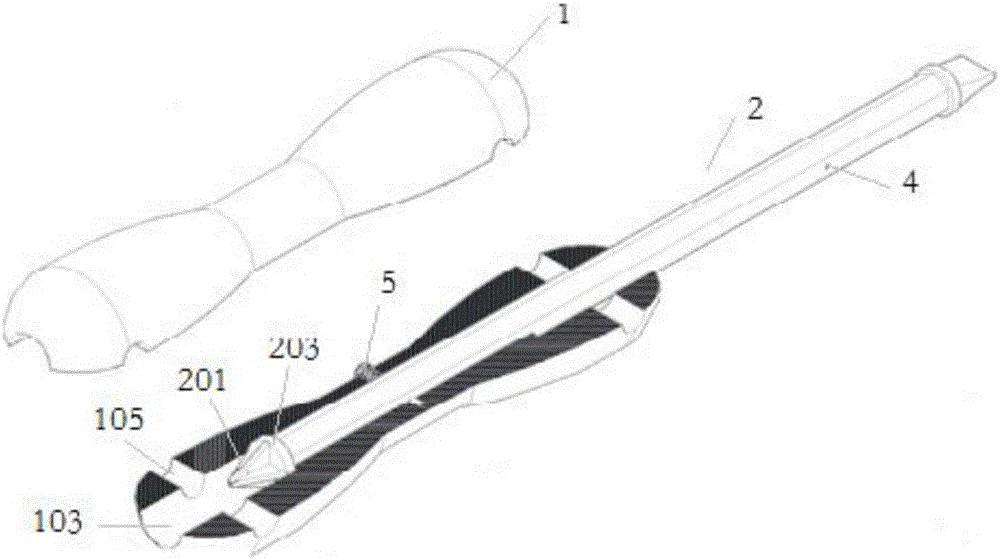

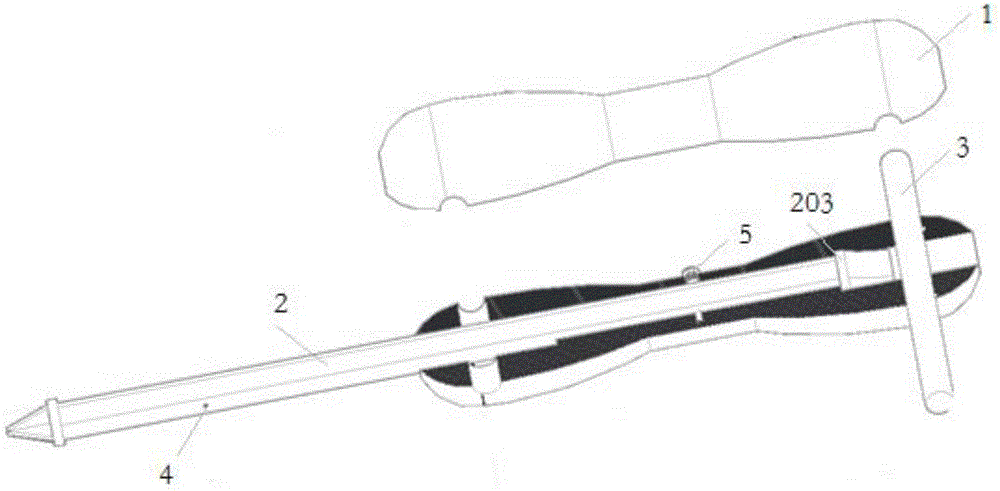

Double-head large-torque screwdriver

The invention discloses a double-head large-torque screwdriver. The double-head large-torque screwdriver comprises a screwdriver handle (1) and a screwdriver rod (2), a first concaved channel (101) is formed in the axial direction of the screwdriver handle (1), and the screwdriver rod (2) is contained inside the first concaved channel; the screwdriver rod (2) slides inside the screwdriver handle to be adjusted to a working position screwdriver head end or keeps a relative fixed position with the screwdriver handle under limiting of a limiting component to limit a working position screwdriver head station; second concaved channels (105) which are perpendicular to the axial direction of the screwdriver handle are further formed in the two ends of the screwdriver handle (1), and a torque rod (3) can be arranged inside each second concaved channel. The problem that an existing screwdriver is inconvenient to replace is solved; meanwhile, large-torque operation is achieved.

Owner:LUOYANG BOZHI AUTOMATIC CONTROL TECH

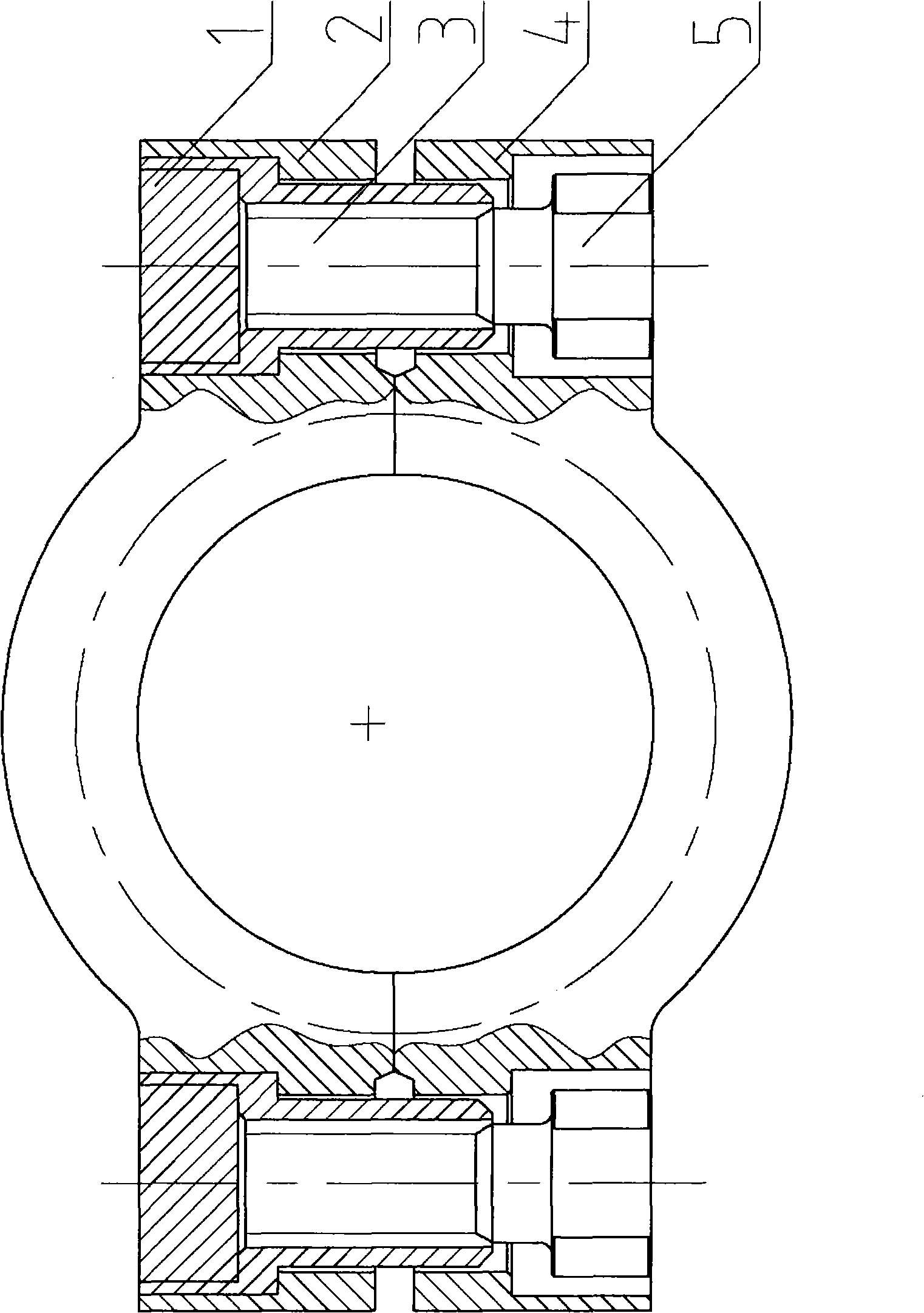

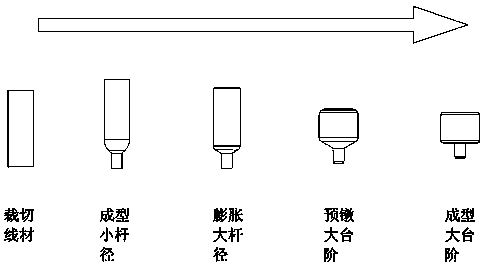

Cold heading forming technology for balancing weight and die structure for pre-heading large step

InactiveCN104325064AExtended service lifeLarge amount of deformationRailway componentsForging/hammering/pressing machinesWire rodUltimate tensile strength

The invention relates to a cold heading forming technology for a balancing weight and a die structure for pre-heading a large step. The technology comprises the technical steps of S1, cutting a wire rod; S2, forming a small rod diameter; S3, expanding a large rod diameter; S4, pre-heating the large step; S5, forming the large step. The die structure comprises a main die unit and a stamp die unit, wherein the main die unit comprises a main die shell; a main die inner die is arranged in the main die shell; a main die base plate is arranged at the bottom of the main die shell; a main die thimble is arranged in the middle of the main die inner die; the stamp die unit comprises a stamp die shell; a forming die is arranged in the stamp die shell; a stamp die base plate is arranged at the bottom of the stamp die shell; a main die cushion block is arranged between the main die inner die and the main die base plate; a forming insert is arranged on the main die inner die; a forming die limiting plate is arranged between the forming die and the stamp die base plate; a stamp die mandril is arranged between the forming die limiting plate and the stamp die base plate. By cold heading, the manufacturing of balancing weights of all sizes, large and small rod diameters and chamfers is realized, and the inner flow line of a product is complete; furthermore, the balancing weight is high in intensity, and the service life of a die is prolonged.

Owner:SUZHOU INDAL PARK XINKAI PRECISION FASTENERSCO

Split bolt assembly and method for mounting wall formwork

InactiveCN108005384ANot stickySimple structureAuxillary members of forms/shuttering/falseworksHeaded largeCushion

The invention relates to a split bolt assembly comprising a split bolt bar, fastening nuts and a sleeve. The split bolt bar is sleeved with the sleeve, the fastening nuts are arranged at the two endsof the split bolt bar; conical plastic hole-forming cushions are arranged at the two ends of the sleeve; cushion plates are arranged between the conical plastic hole-forming cushions and the fasteningnuts; a thread rope is wound around the middle of the split bolt bar; multiple grooves are formed in the large end faces of the conical plastic hole-forming cushions; and the outer surfaces of the conical plastic hole-forming cushions are covered with woven fabrics. The split bolt assembly is simple in structure, reasonable in design and convenient to use, the split bolt bar is not liable to stick to concrete and thus can be reused for multiple times, and the construction cost is reduced.

Owner:CHINA THIRD METALLURGICAL GRP

45-degree cutting frame of Roman head large lace

ActiveCN105269706AThe structure is novel and uniqueImprove work efficiencyWorking accessoriesStone-like material working toolsEngineeringHeaded large

A 45-degree cutting frame of Roman head large lace is specifically composed of a frame body, a left angle supporting rod and a right angle supporting rod. The left angle supporting rod is arranged on the left frame face of the frame body. The right angle supporting rod corresponding to the left angle supporting rod is arranged on the right frame face of the frame body to form the whole 45-degree cutting frame of the Roman head large lace. When the 45-degree cutting frame is applied, after materials are fixed, the cutting process is finished at a time, and the work efficiency is greatly improved. By means of the 45-degree cutting frame, the angle of the left side and the angle of the right side of the large lace materials can be adjusted at will. By means of the 45-degree cutting frame, the cut scrap edge is very accurate in angle, and when the Roman large lace is spliced, the door frame fit goodness is very appropriate, and the quality of a door is greatly improved. By means of the 45-degree cutting frame, after panels are fixed, moving is not likely to happen, and safety accidents that the panels vibrate and the panels jump and hit people cannot be caused.

Owner:GUANGXI SHUANGYING DOORS CO LTD

Fastening device

InactiveUS20160157591A1Inexpensive and flexibleEasy to fixSnap fastenersTravelling carriersEngineeringMechanical engineering

Owner:HEAVEN SENT GAMING

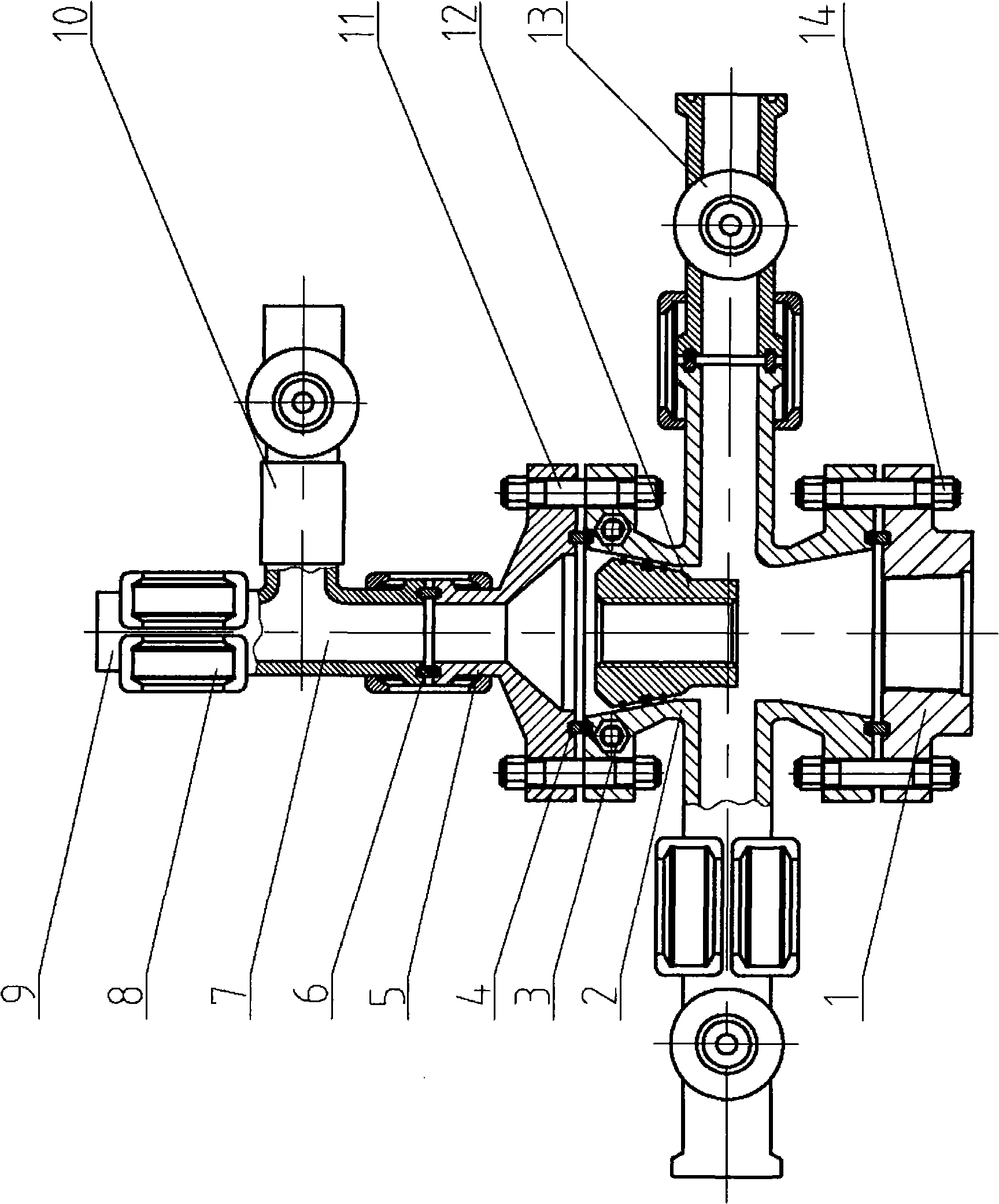

A seesaw type hydraulic control pin reversing reset device for power tongs

ActiveCN103993844BTo achieve the purpose of remote hydraulic controlInnovative designDrilling rodsDrilling casingsEngineeringShackle

Owner:盐城特达钻采设备有限公司

Filled noodle making machine

InactiveCN107691554AIngenious ideaSimple structureDough extruding machinesComing outMechanical engineering

The invention relates to a sandwich noodle machine, which comprises a machine frame, a noodle container, a stuffing container, a piston, a piston rod, a power device connection, etc. The bottom of the noodle container is equipped with a plate-shaped cutter head, and the filling container The bottom is provided with a plate-shaped stuffing knife head, there is a gap between the dough knife head and the filling knife head, and several round holes are respectively arranged on the dough knife head and the stuffing knife head, and the round holes on the filling knife head The diameter is smaller than the round hole on the face cutter head, and each round hole on the filling head is in one-to-one correspondence with the round holes on the face cutter head. It is also concentric with the filling knife head, and the round hole of the filling knife head is larger than that of the filling knife head, and then the final sandwich noodles are completed by applying pressure on the dough and filling. The idea is ingenious, the structure is simple, and the cost is low. , high efficiency, easy to use, easy to popularize and apply.

Owner:游文

Truck-mounted skid-mounted-type multifunctional oil production machine

The invention discloses a truck-mounted skid-mounted-type multifunctional oil production machine. The truck-mounted skid-mounted-type multifunctional oil production machine is novel oil gas discharging and producing equipment, the design that a well-head large pulley supported by a telescopic arm form replaces a vertical column of an original oil pumping unit is adopted, downhole accessories are connected by adopting steel wire ropes special for oil production, and discharging and producing are conducted through matching of a winding drum motor and electronic control equipment. The structure equipment is truck-mounted equipment, fixed-pry-block-type single well oil production operation and moving oil bailing operation between a plurality of wells can both be conducted, power can be provided by grid electricity, an electricity generator can also be additionally mounted to serve as a power supply under the conditions of remote oil wells, well exploring swabbing for production and the like, the oil production equipment is remarkable in cost performance advantage under the low oil price, the equipment cost is reduced by a large margin, and the discharging and producing efficiency is improved.

Owner:TIANJIN JL RAILWAY TRANSPORT EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com