Formwork connecting piece

A connecting piece and formwork technology, which is applied to formwork/formwork/work frame connectors, on-site preparation of building components, and construction, etc., can solve the impact of single-person high-altitude work, impact on construction efficiency, and impact on workload, etc. problems, to achieve the effect of facilitating material management, promoting construction efficiency, and reducing material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

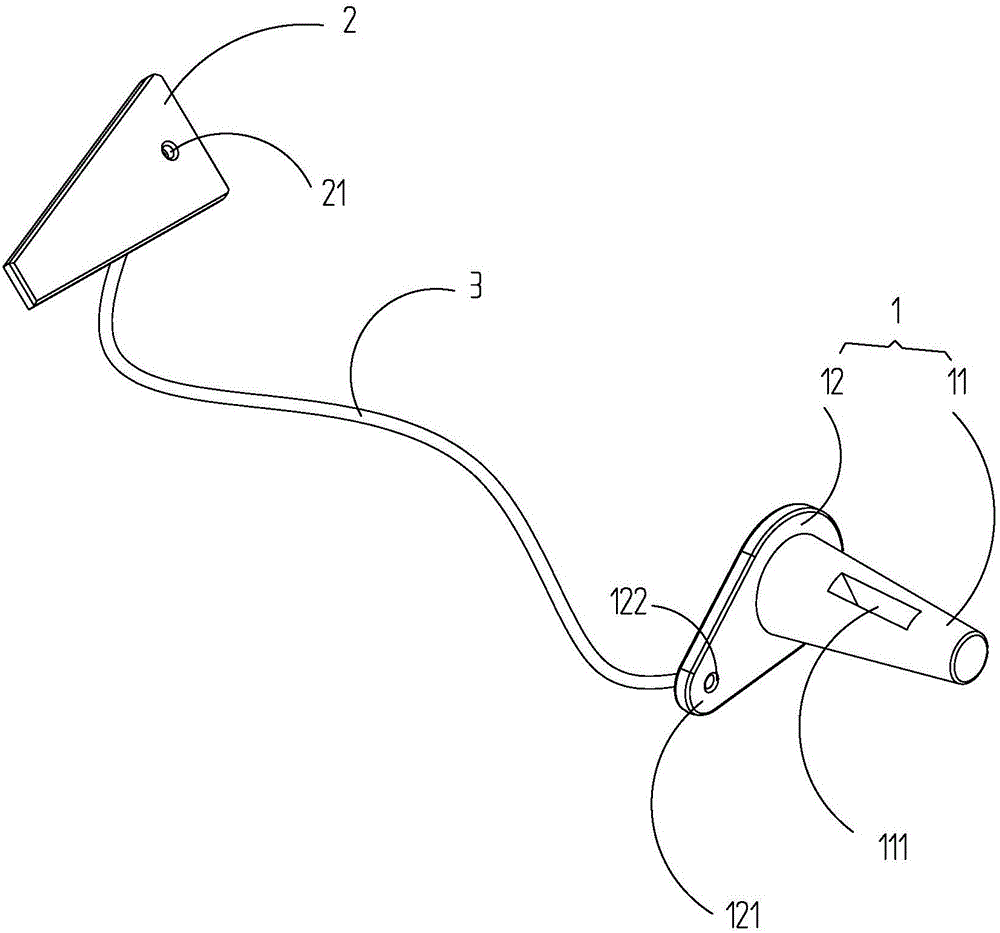

[0012] Referring to the accompanying drawings, a formwork connector of the present invention includes a pin 1, a pin piece 2 and a connecting rope 3 connecting the pin 1 and the pin piece 2; The nail cap 12 has a pin hole 111 on the pin body 11 , and a protruding portion 121 is formed on one side of the nail cap 12 . The nail cap 12 has a protruding portion 121. Compared with the circular nail cap 12 in the related art, it can give construction workers a position to insert the pin 1 on the aluminum template, and the pin hole 111 is displayed in front of the eyes, which is convenient for the pin 2. into. In addition, when the protruding portion 121 is used as a U-groove on the inner side of the template, the pin 1 is stressed when the pin piece 2 is driven in, and acts as a stop for the pin 1, preventing the rotation of the pin 1 from affecting the forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com