Polycrystalline diamond contact for well drilling and rock crushing tool

A polycrystalline diamond, drilling rock breaking technology, applied in drilling equipment, drill bits, earthwork drilling and other directions, can solve the problems of reducing the effective working pressure on bit, weakening the ability of PDC teeth to penetrate into the rock, etc., to improve the rock breaking efficiency. , the effect of reducing the pressure bearing area and increasing the specific pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

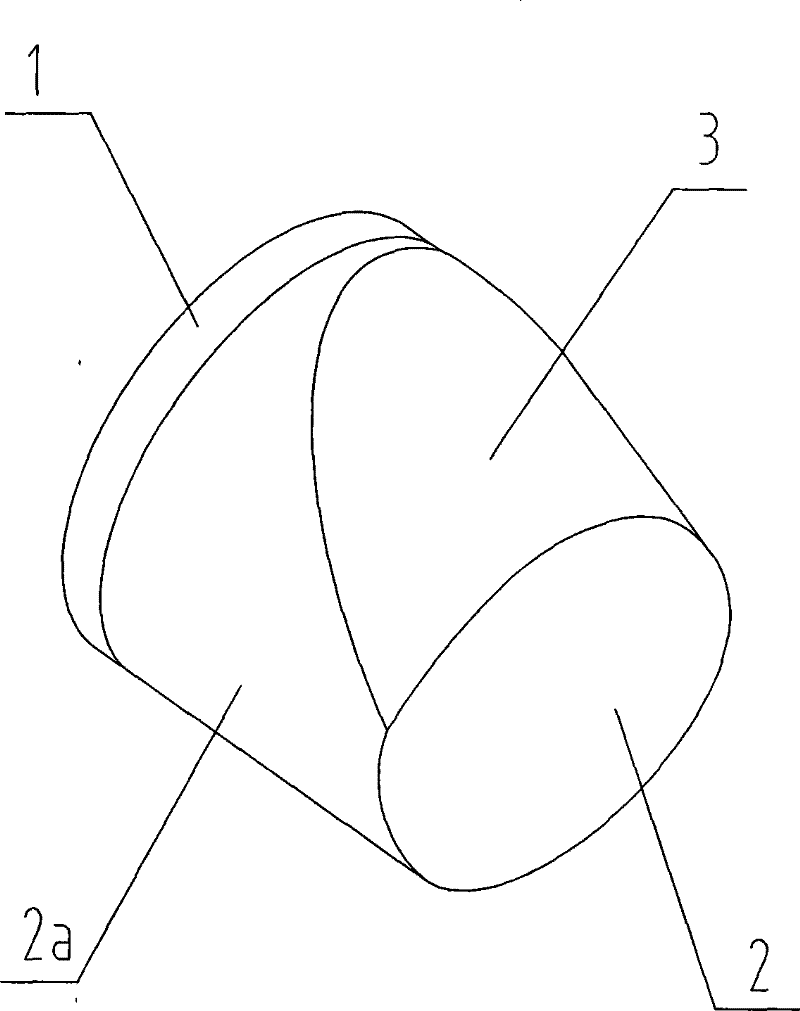

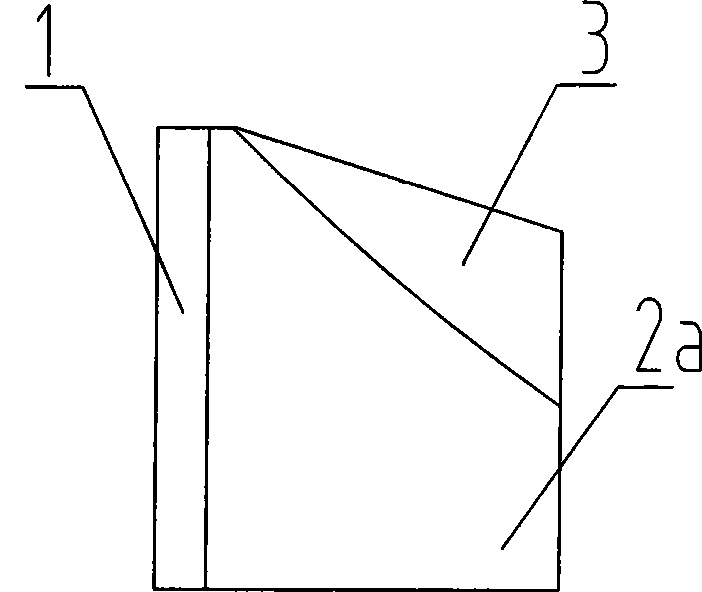

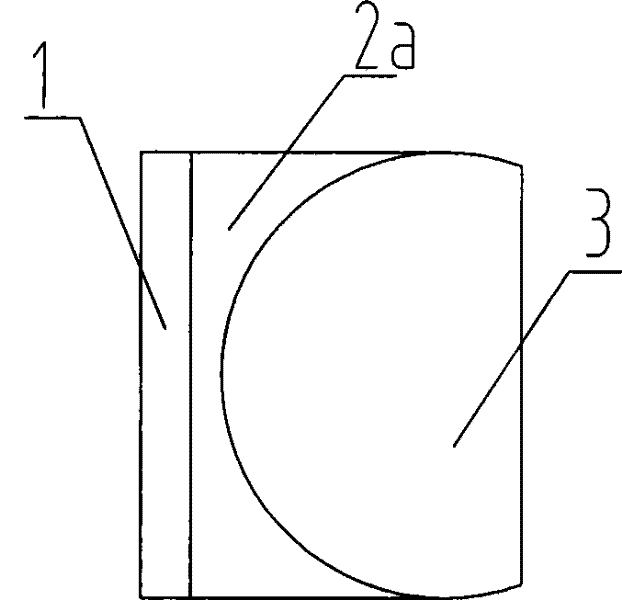

[0026] Example: such as figure 1 , 2 , 3, 4, 5, 6, and 7: a polycrystalline diamond composite sheet for drilling and rock-breaking tools, the composite sheet is a cylinder, including a polycrystalline diamond layer 1 and a matrix 2 composited therewith, The matrix of the composite sheet is formed by the remaining part after obliquely cutting a convex curved surface, and the side after cutting is composed of the original cylindrical surface 2a and the new convex curved surface 3, so that the composite sheet body has two ends of large and small , wherein one end with the polycrystalline diamond layer 1 is a large end, and the other end is a small end. The convex curved surface 3 is a conical surface or a cylindrical surface. The bottom surface of the base body 2 is in the shape of a crescent.

[0027] The key of the present invention is to cut away a piece on the original cylindrical base, so that the side of the base has an inclined convex surface, from the three-dimensiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com