Fixed cutting-tooth drilling bit

A technology of cutting teeth and drill bits, which is applied in construction and other fields, can solve problems such as difficult to reach and high working life, and achieve the effects of increasing exposure height, improving service life, and improving rock breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

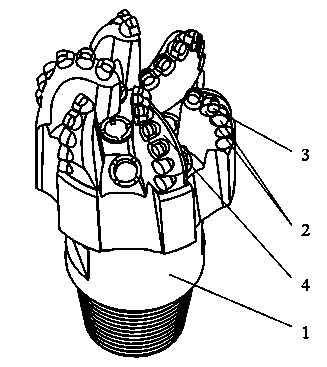

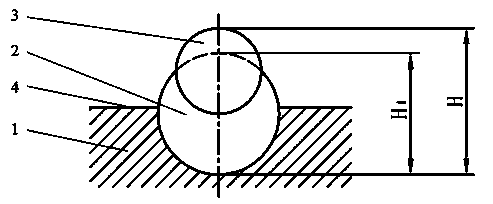

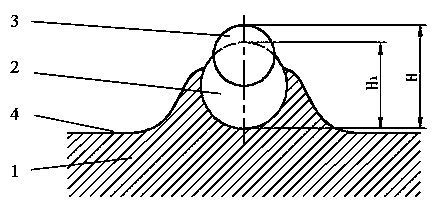

[0047] Such as Figure 1 to Figure 8 As shown, a fixed cutter bit with a stacked tooth structure includes a drill body 1 and a cutting tooth. The cutting tooth is composed of a base tooth 2 and a stacked tooth 3. 2 is provided with a groove 5 that matches the shape of the stacked tooth 3, and the stacked tooth 3 is fixed in the groove 5 of the base tooth 2. The total height H of the stacked tooth structure formed by the stacked tooth 3 and the base tooth 2 is greater than The theoretical height H of the base tooth 1 . The base teeth 2 and stacked teeth 3 are respectively selected from PDC composite chips, thermally stable polycrystalline diamond cutting teeth, natural diamond cutting teeth, impregnated diamond cutting teeth, carbide cutting teeth, cubic boron nitride cutting teeth, ceramic cutting teeth , or, cutting teeth containing diamond or cubic boron nitride. The rear end of the base tooth can be a spherical surface (such as Figure 4 shown) or flat (as Figure 5 sh...

Embodiment 2

[0049] This embodiment is basically the same as Embodiment 1, the difference being that the theoretical profile of the cutting edge of the base tooth 2 is non-circular. Such as Figure 9 As shown, the cutting edge profile of the base tooth 2 is elliptical, which can significantly increase the wear height of the base tooth and the entire stacked tooth structure.

Embodiment 3

[0051] This embodiment is basically the same as Embodiment 1, the difference is that the cutting edge profile of the stacked teeth 3 is non-circular. Such as Figure 10 As shown, the cutting edge profile of stacked teeth 3 is a sharp wedge-shaped profile composed of straight line segments and arcs, which can enhance the ability of the cutting teeth to penetrate into the formation, and is more suitable for drilling in harder formations;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com