Pile head large-diameter steel bar straightening device

A technology of large-diameter steel bars, which is applied in the field of large-diameter steel bar straightening devices at pile heads, can solve problems such as difficulty in straightening large-diameter steel bars, labor-intensive large-diameter steel bars, and low efficiency, so as to save manpower, increase production efficiency, and mechanize high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

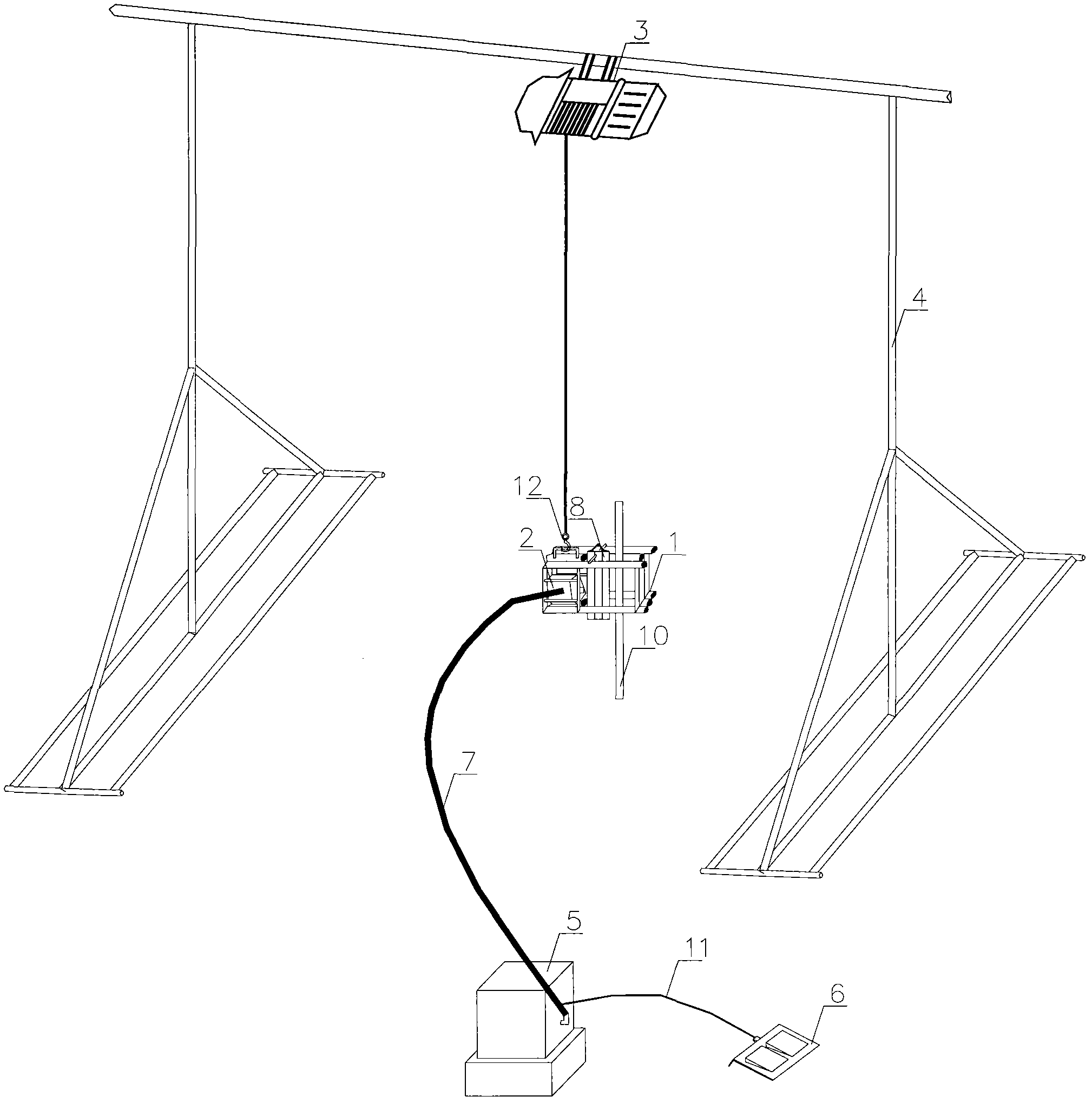

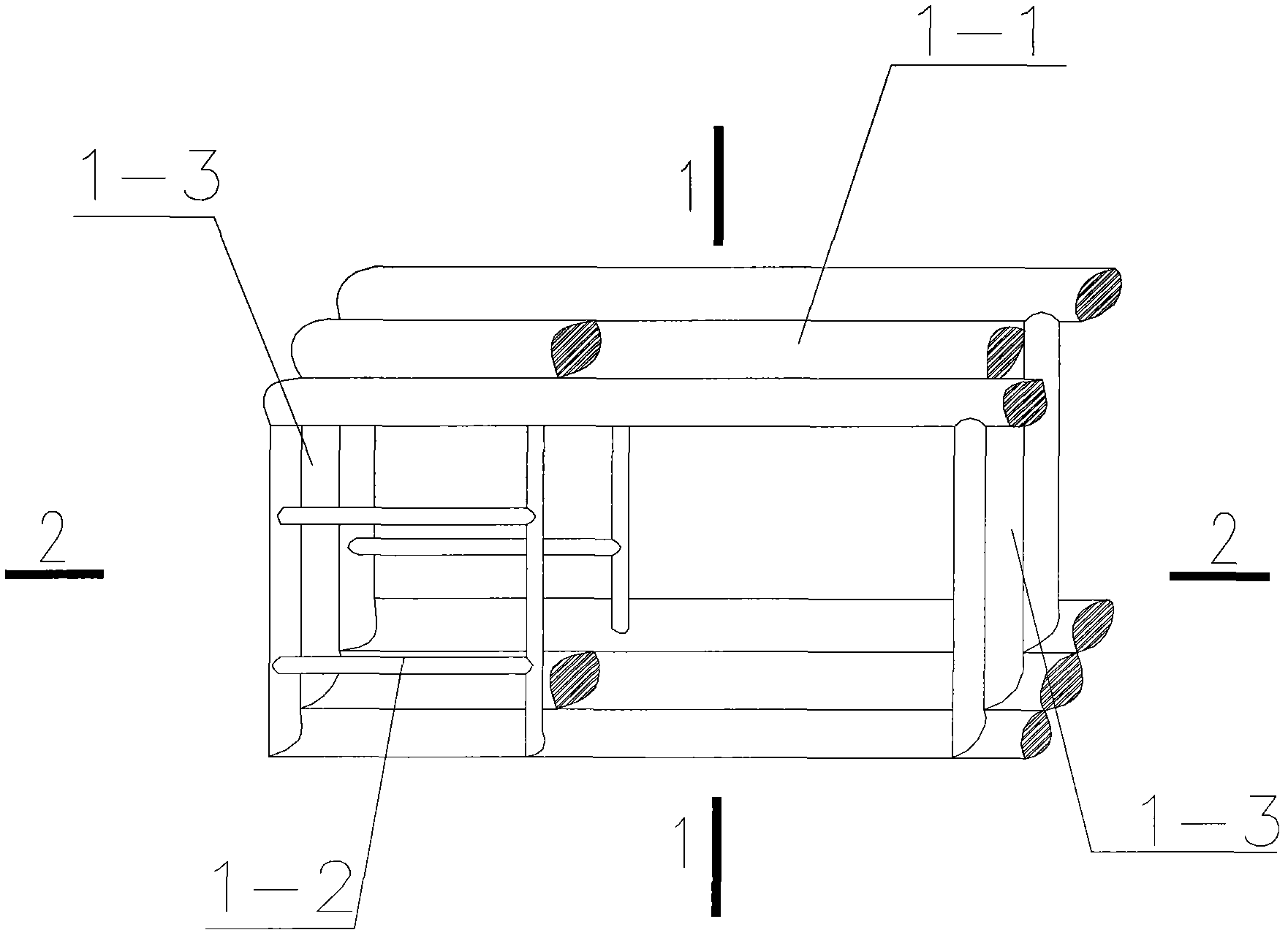

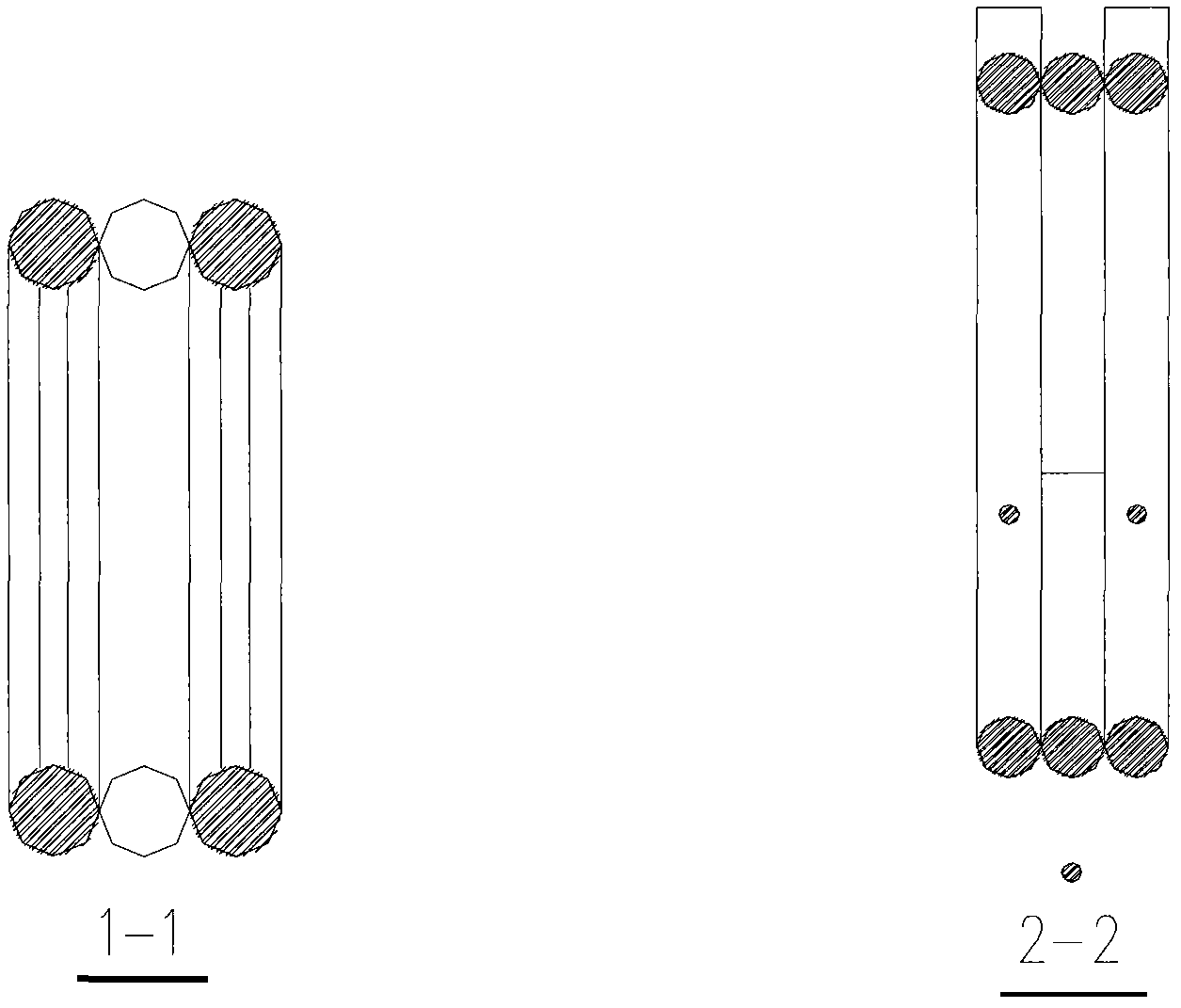

[0027] Embodiment one: see Figure 1-Figure 8 , Figure 10 In the figure, a large-diameter steel bar straightening device at the pile head includes a bracket, a lifting mechanism, a hydraulic straightening mechanism, a hydraulic power and a control system, and the hydraulic straightening mechanism includes a straightening frame, a movable pressure rod, and a The hydraulic cylinder in the straightening frame, the middle part of the straightening frame is provided with a straightened steel bar insertion hole transparent up and down, the movable pressure rod is inserted into the straightened steel bar insertion hole, and the hydraulic cylinder piston rod The direction of travel is perpendicular to the insertion hole of the straightened steel bar. The lifting mechanism is an electric hoist, and the wire rope hook of the electric hoist is connected with the adjustment frame. The hydraulic power and control system includes a hydraulic pipe, a hydraulic pump station, and an electri...

Embodiment 2

[0028] Embodiment two: see Figure 1-Figure 7 , Figure 9 , Figure 10 A large-diameter steel bar straightening device at a pile head, including a bracket, a lifting mechanism, a hydraulic straightening mechanism, a hydraulic power and a control system, and the hydraulic straightening mechanism includes a straightening frame, a movable pressure rod, and is installed in the straightening frame The middle part of the straightening frame is provided with a straightened steel bar insertion hole transparent up and down, the movable pressure rod is inserted into the straightened steel bar insertion hole, and the traveling direction of the piston rod of the hydraulic cylinder It is perpendicular to the insertion hole of the straightened steel bar. The lifting mechanism is an electric hoist, and the wire rope hook of the electric hoist is connected with the adjustment frame. The hydraulic power and control system includes a hydraulic pipe, a hydraulic pump station, and an electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com