45-degree cutting frame of Roman head large lace

A cutting frame, large lace technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., to achieve the effect of improving quality, improving work efficiency, and precise edge cutting angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Now in conjunction with accompanying drawing, the present invention is described in detail:

[0028] The invention is composed of a frame body (1), a left angle support rod (2) and a right angle support rod (3).

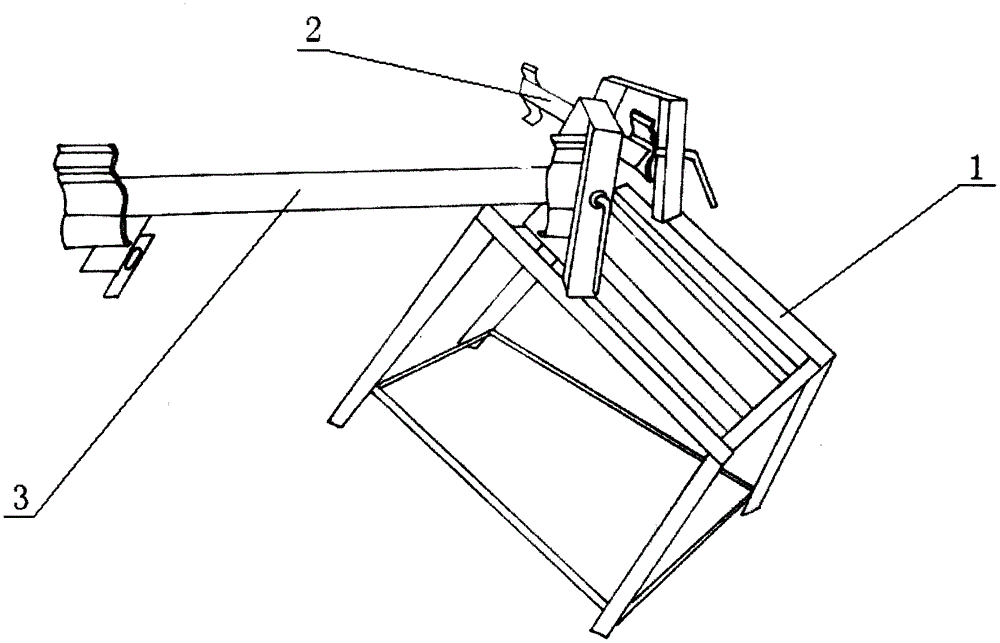

[0029] figure 1 Shown is the structural representation of the present invention. 1 is a frame body (1), 2 is a left angle support rod (2), and 3 is a right angle support rod (3).

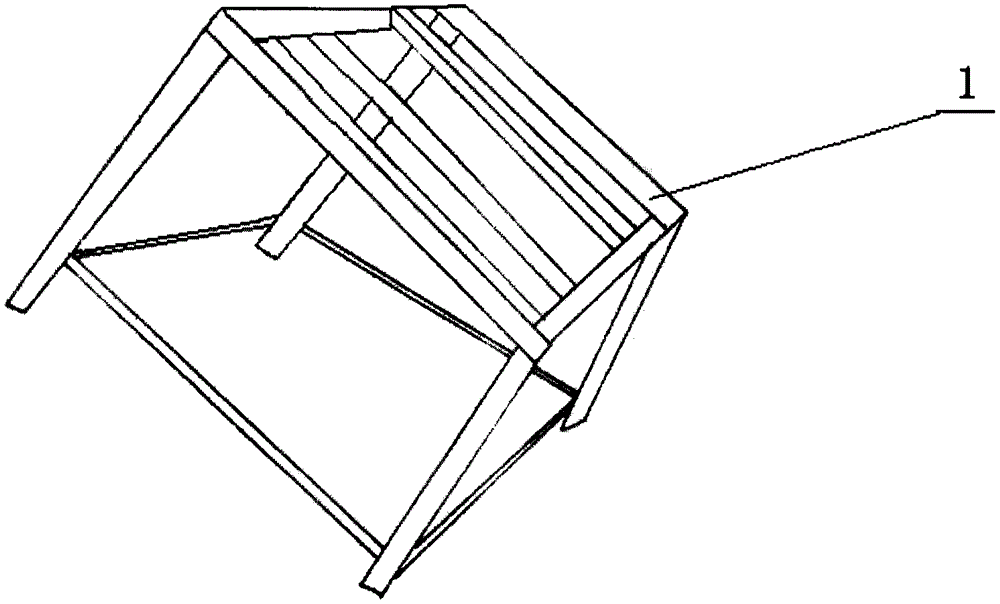

[0030] figure 2 Shown is a schematic structural view of the frame (1) in the present invention. The frame body (1) is a square three-dimensional frame.

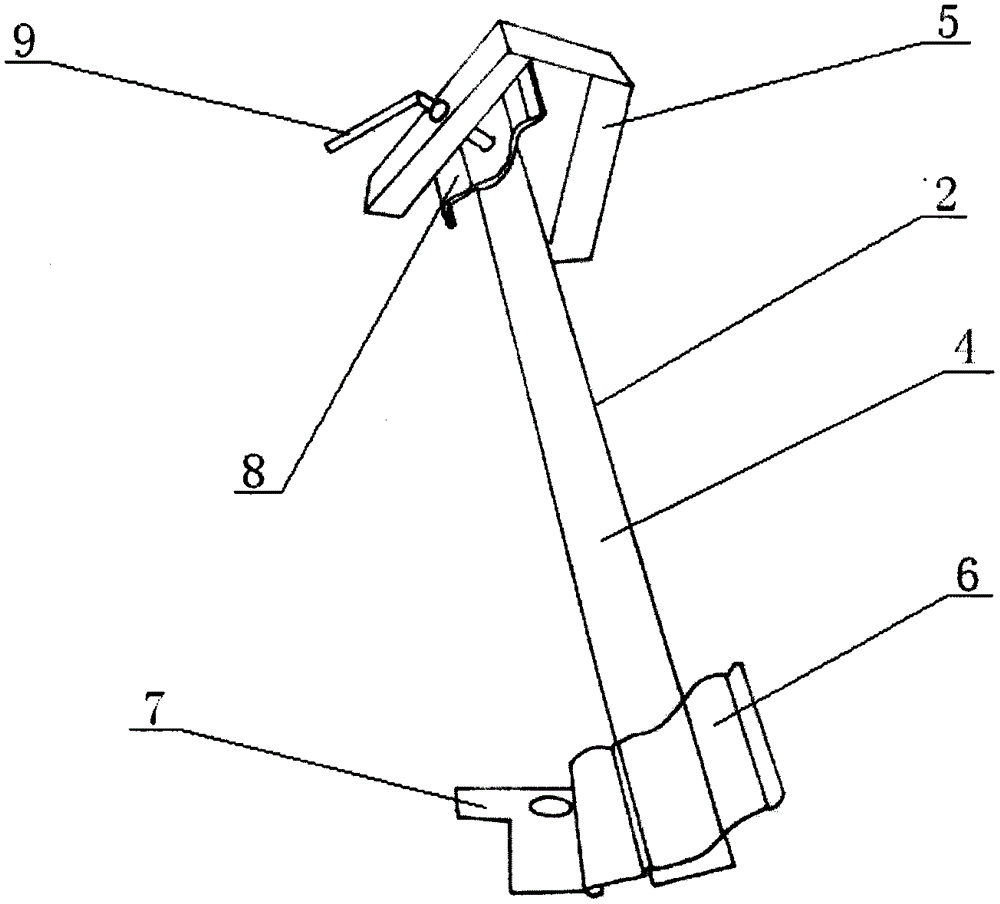

[0031] image 3 Shown is the structural representation of the left angle support rod (2) in the present invention. The left angle support bar (2) is made of connecting rod one (4), support one (5), lace fixed frame one (6), stable frame one (7), lace fixed frame two (8), fastening handle one (9) form, wherein, the rear end of connecting rod one (4) is arranged on the right foot frame of support one (5), and lace fixing fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com