A wire drawing device for door panel surface

A door panel surface and door panel technology, which is applied to the parts of grinding machine tools, grinding workpiece supports, grinding machines, etc., can solve the problem of wire drawing direction, uneven depth, dust damage to workers' physical and mental health, and different effects of drawing lines, etc. problem, to achieve the effect of novel and unique structural composition, high degree of automation, stable direction and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Now in conjunction with accompanying drawing, the present invention is described in detail:

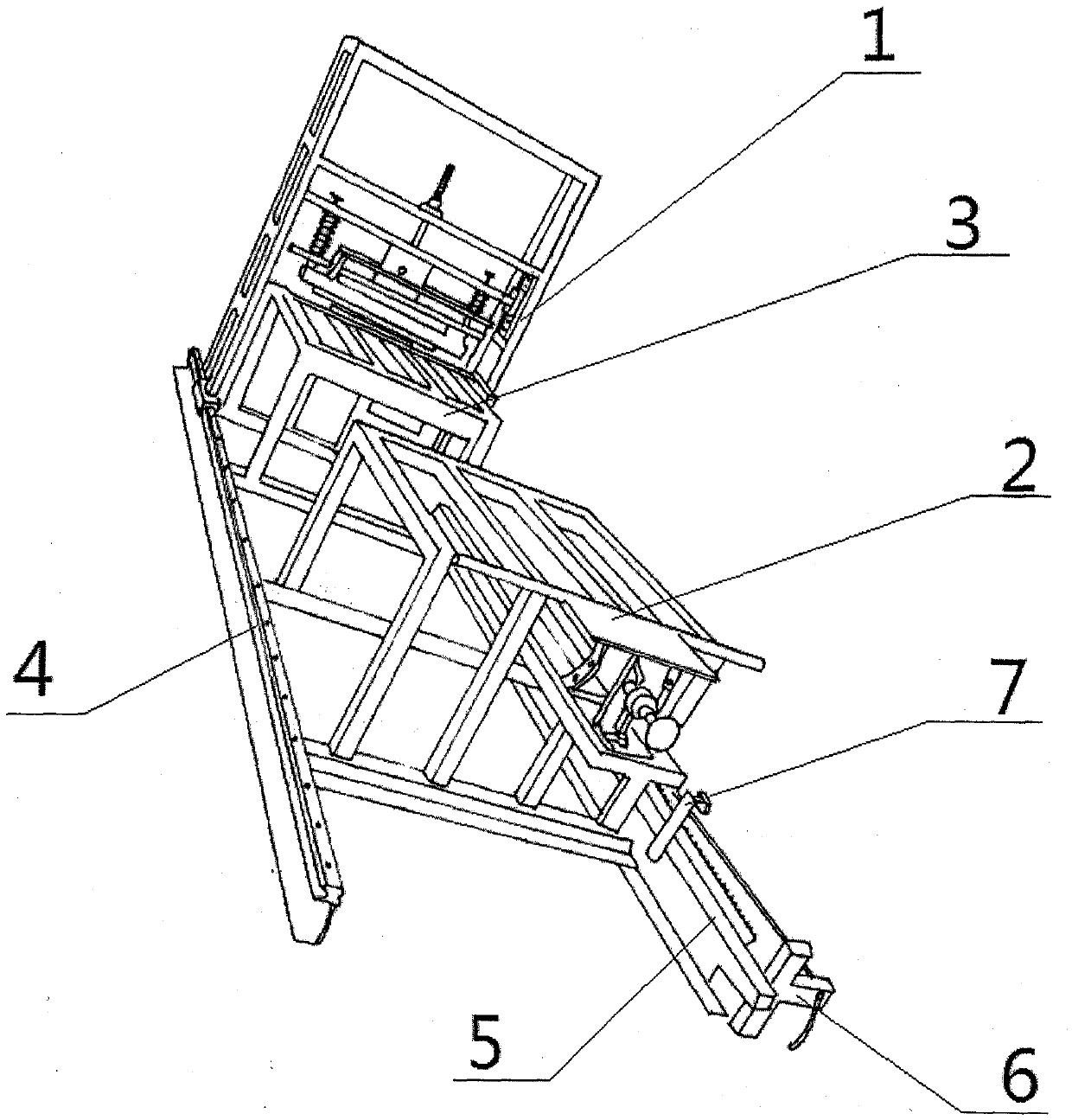

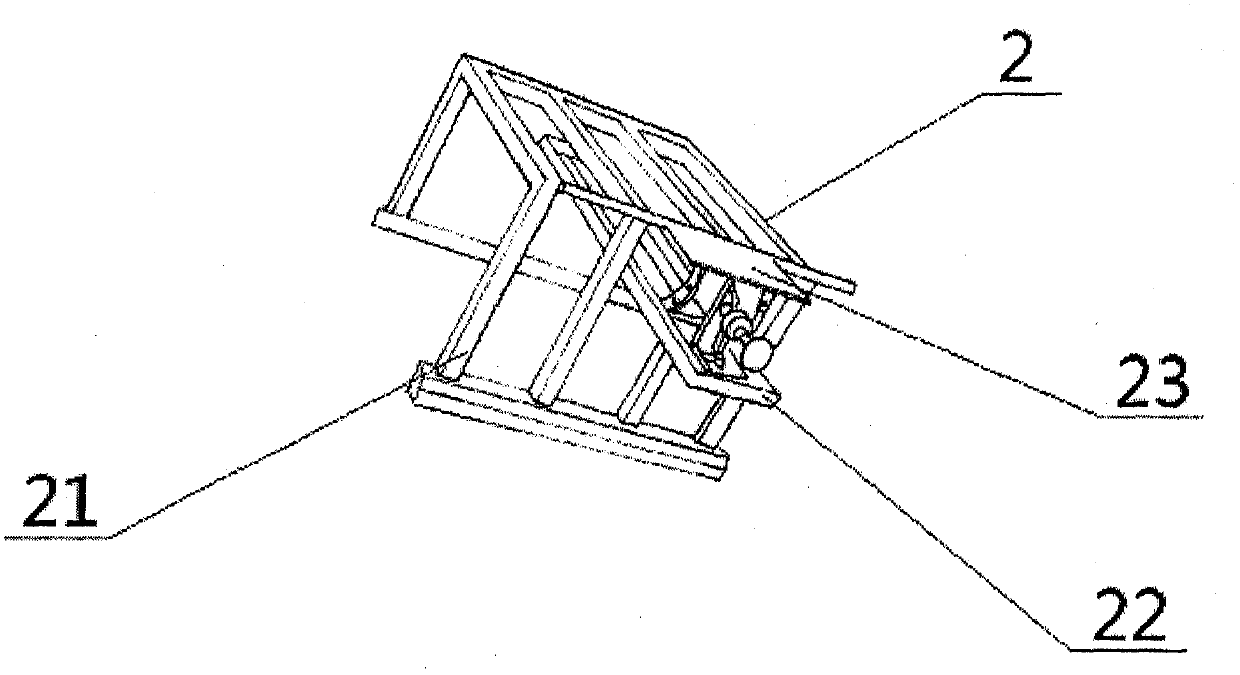

[0039]The present invention is composed of a wire drawing machine transmission frame (1), a front frame (2) for placing a door panel, a rear frame (3) for placing a door panel, a guide rail (4), a gear guide rail (5), a solenoid valve (6), and a wire fixing frame (7). )composition.

[0040] figure 1 Shown is the structural representation of the present invention. Among them, 1 is the wire drawing machine transmission frame (1), 2 is the front frame for door panel placement (2), 3 is the rear frame for door panel placement (3), 4 is the guide rail (4), 5 is the gear guide rail (5), and 6 is the electromagnetic Valve (6), 7 are electric wire holders (7).

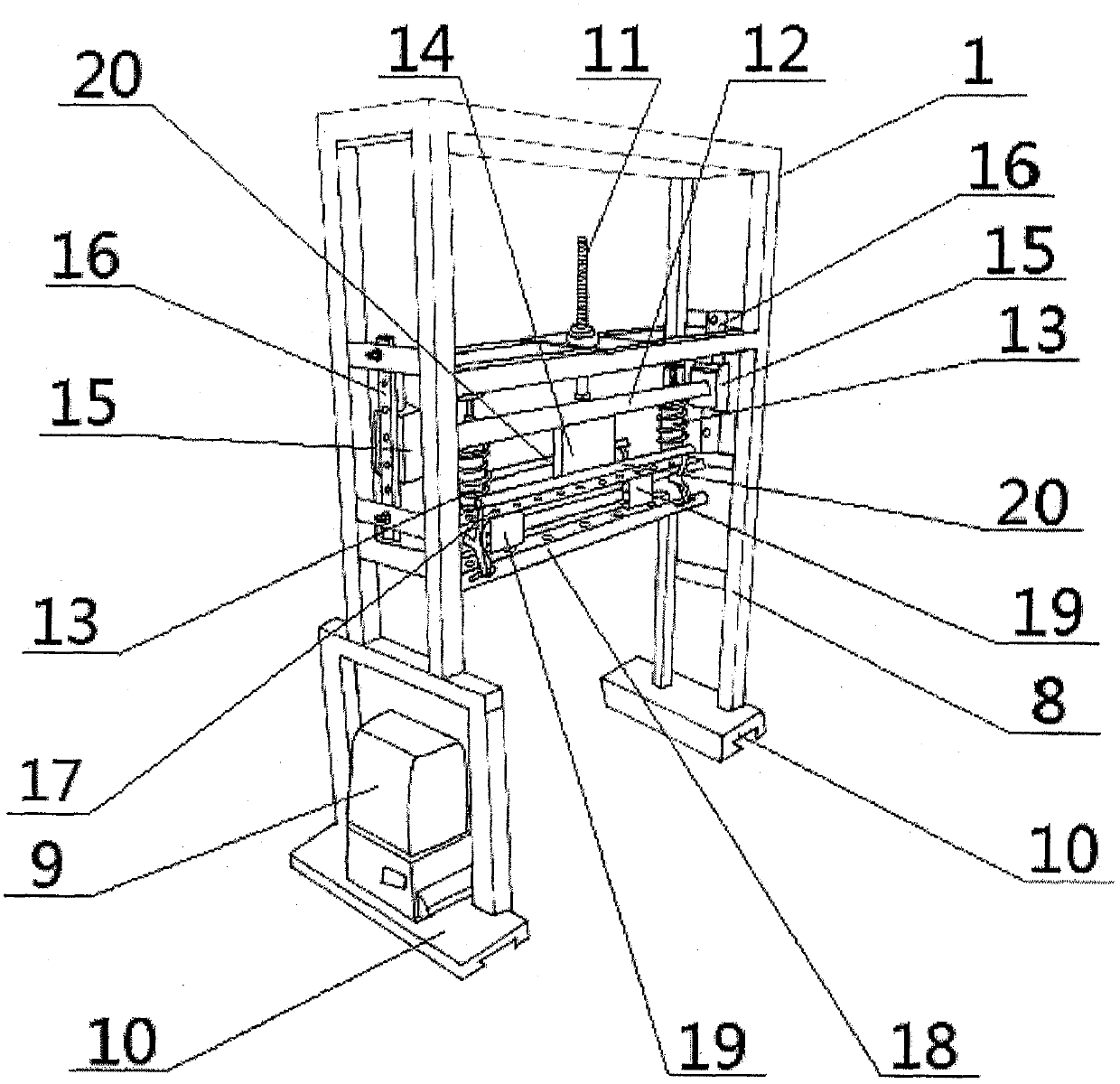

[0041] figure 2 Shown is the schematic structural view of the wire drawing machine driving frame (1) in the present invention. The wire drawing machine transmission frame (1) is composed of a frame body two (8), a motor (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com