A numerically controlled exterior automatic positioning device for a door panel

An automatic positioning and door panel technology, applied in positioning devices, feeding devices, storage devices, etc., can solve the problems of no positioning, error-prone, slow speed, etc., and achieve fast speed, stable quality and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with accompanying drawing, the present invention is described in detail:

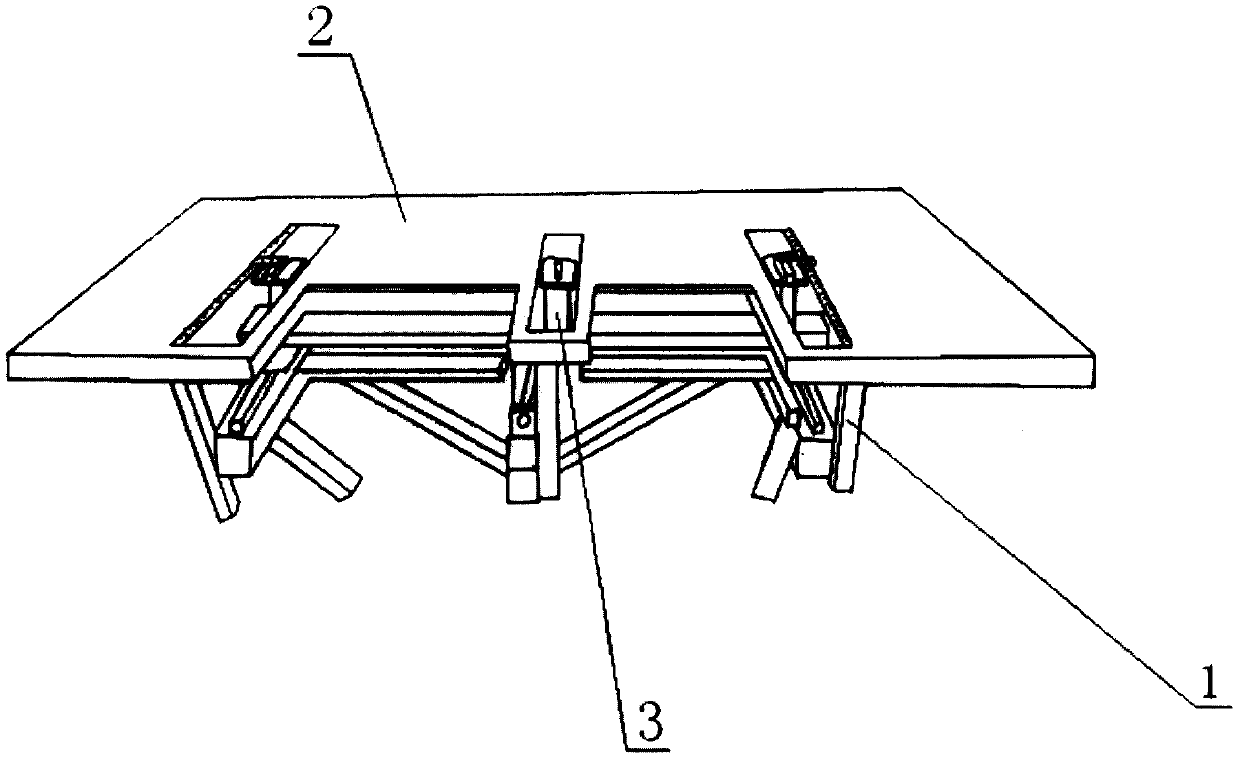

[0029] The present invention is made up of frame body 1, workbench 2, positioning movable frame 3.

[0030] figure 1 Shown is the structural representation of the present invention. Wherein, 1 is a frame body, 2 is a workbench, and 3 is a positioning movable frame.

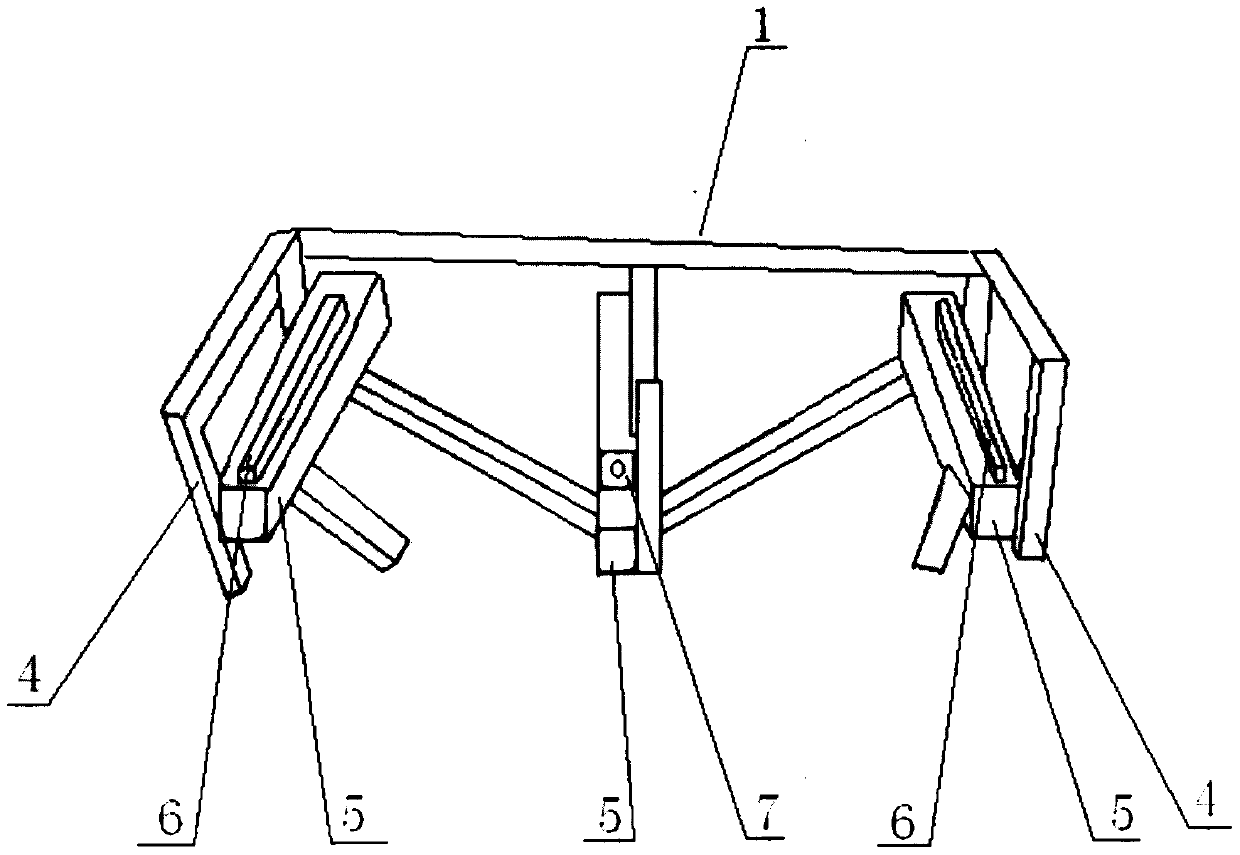

[0031] figure 2 Shown is a schematic structural view of the frame body 1 in the present invention. Frame body 1 is made up of frame foot 4, fixed frame 5, sliding pin 6, movable frame 7, and wherein fixed frame 5 has three in all, is arranged in the left, middle, right of frame body 1 respectively; There are two sliding pins 6, They are arranged on the left and right fixed frames 5 respectively; the movable frame 7 is arranged on the fixed frame 5 in the middle.

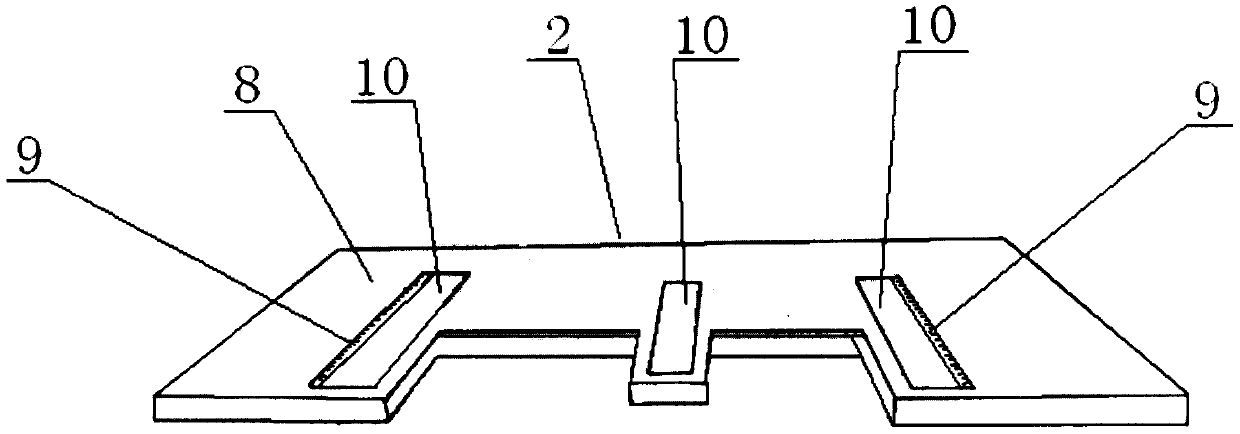

[0032] image 3 Shown is a schematic structural view of the workbench 2 in the present invention. The workbench 2 is composed of a bench 8 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com