Colored diamond scratch-resistant protective film and manufacturing method thereof

A technology of protective film and anti-scratch layer, applied in chemical instruments and methods, layered products, natural mineral layered products, etc., to achieve the effects of easy installation, fast automatic exhaust speed, and strong fashion sense

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

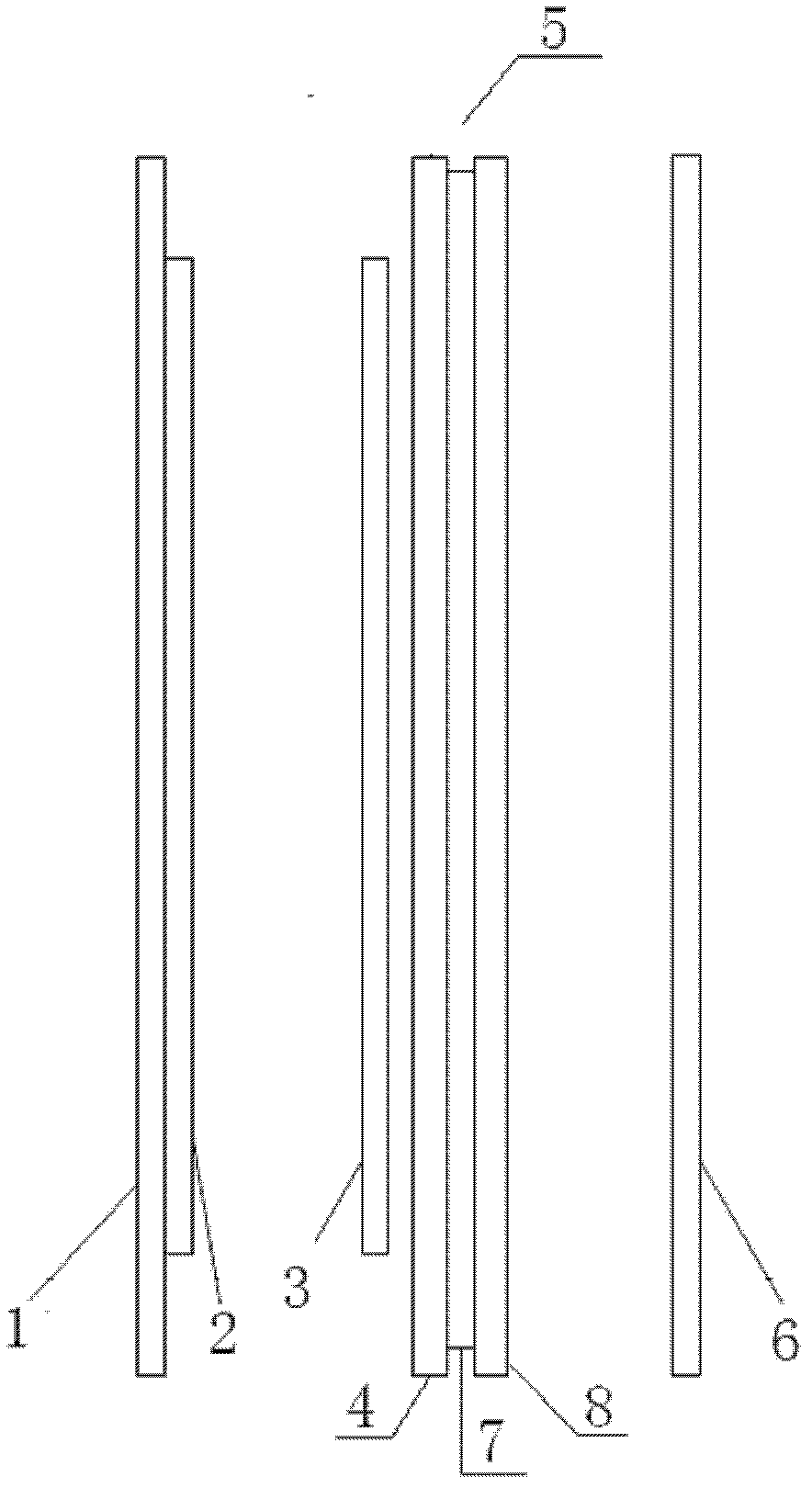

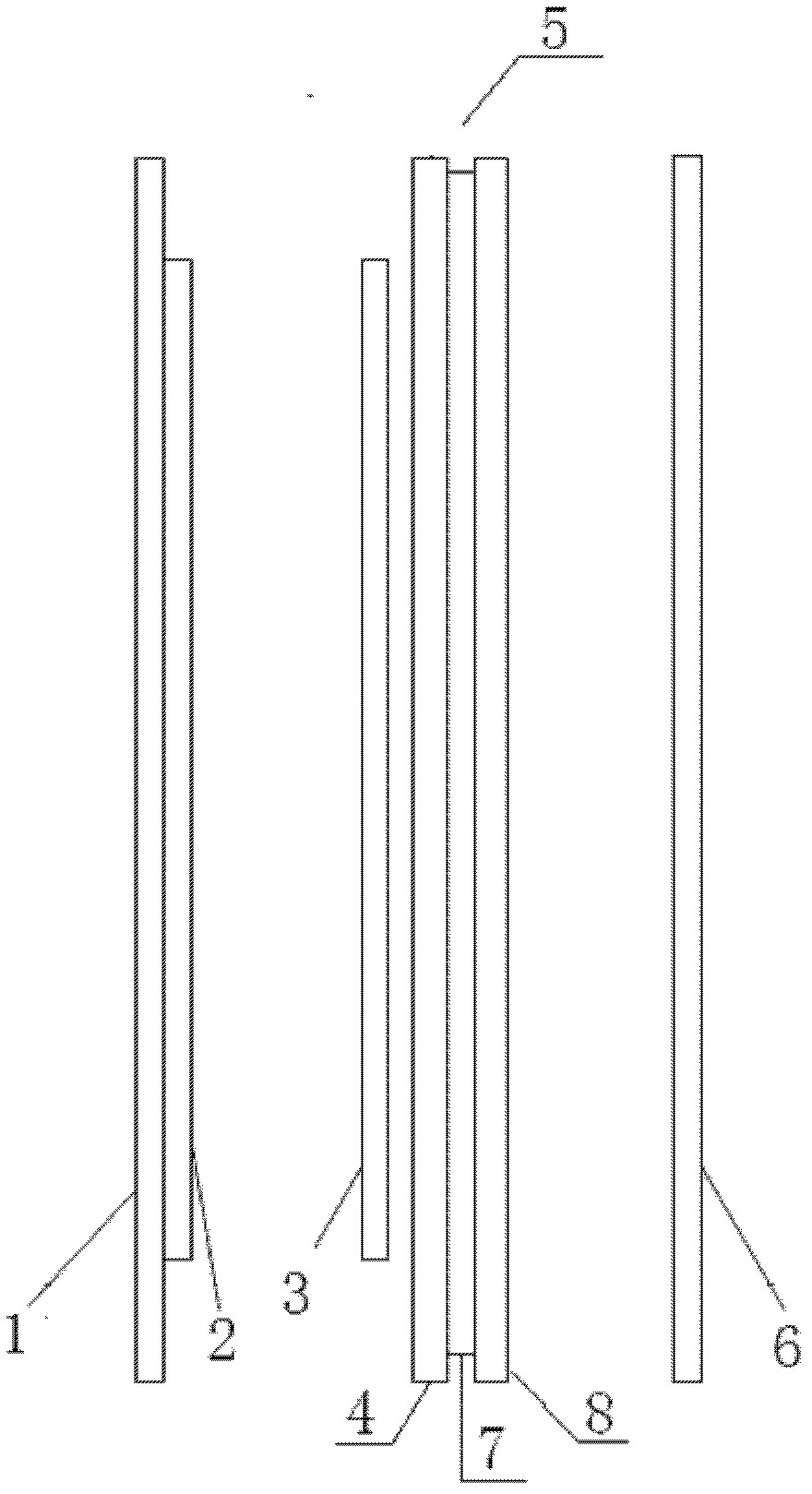

[0027] Such as figure 1 Shown, a kind of colored diamond anti-scratch car protective film, it comprises: thickness is the anti-scratch layer protective film PET substrate layer 1 of 50um, the thickness is the protective film adhesive layer 2 of 5um, the thickness is the anti-scratch layer 3 of 5um, The installation adhesive layer 5 with a thickness of 250um and the installation adhesive protective film PET substrate layer 6 with a thickness of 50um; wherein, the installation adhesive layer 5 is coated on the main film PET substrate layer 4 with a thickness of 108um. 100um colored diamond silica gel precoat 7 and 42um silica gel layer 8 on the material layer 4 are composited, and the colored diamond silica gel precoat 7 contains colored diamond colored diamond powder (purchased from Zhejiang Yiwu Huayi Pigment Co., Ltd.), It uses natural mica as the base material, and the surface is coated with titanium dioxide; the average particle size of the colored diamond powder is 400 mes...

Embodiment 2

[0035] Such as figure 1 As shown, a colored diamond anti-scratch screen protective film, which includes: a scratch-resistant layer protective film PET substrate layer 1 with a thickness of 36um, a protective film adhesive layer 2 with a thickness of 10um, a scratch-resistant layer 3 with a thickness of 20um, A thickness of 5um installation adhesive layer 5 and a thickness of 12um installation adhesive protective film PET substrate layer 6; wherein, the installation adhesive layer 5 is coated on the main film PET substrate layer 4 with a thickness of 205um. 50um colored diamond silica gel precoat 7 and 25um silica gel layer 8 on the material layer 4 are composited, and the colored diamond silica gel precoat 7 contains transparent diamond colored diamond powder (purchased from Zhejiang Yiwu Huayi Pigment Co., Ltd.), It uses natural mica as the base material, and the surface is coated with titanium dioxide; the average particle size of the colored diamond colored diamond powder i...

Embodiment 3

[0043] A kind of colored diamond anti-scratch automobile protective film, other is the same as embodiment 1, the difference is that the colored diamond silica gel pre-coat layer 7 contains crystal colored diamond powder, diamond magic color diamond powder, and crystal magic color diamond powder. One or more mixtures, wherein the average particle size of the three colored diamond powders is 800 mesh, flat, with a thickness of 4-6um, a width of 140-150um, and a length of 140-160um, all of which are available on the market.

[0044] The colored diamond anti-scratch car protective film prepared in this embodiment has colored diamonds and glittering gold, and is especially attractive to young people.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com