Full-scale-movement linear circulating accelerated loading test system

A technology of accelerated loading and test system, applied in the application of repetitive force/pulsation force to test material strength, impact test, machine/structural component test, etc. problems, to achieve the effect of convenient transition efficiency, high efficiency, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

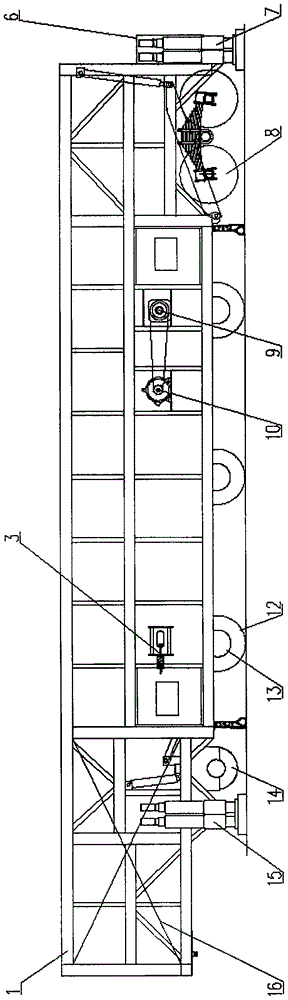

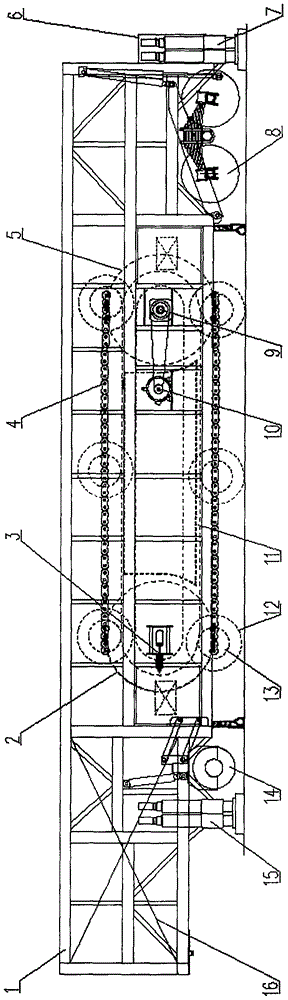

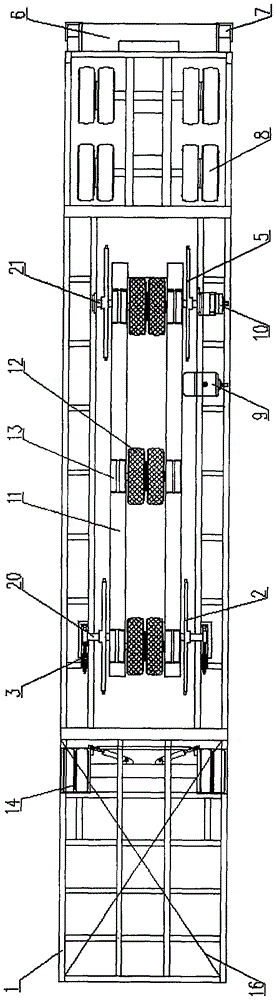

[0029] Attached below Figure 1-5 , a full-scale moving linear circulation accelerated loading test system of the present invention will be described in detail below.

[0030] as attached Figure 1-5 As shown, a kind of full-scale mobile linear circulation type accelerated loading test system of the present invention comprises:

[0031] A frame 1 for fixing the guide rail 11, the chain transmission pair and the power mechanism. The lower part of the frame 1 is fixed with the front travel guide wheel 14 and the rear travel wheel 8 through the link type hydraulic lifting mechanism, which is controlled by the link type hydraulic lifting mechanism The lifting of front walking guide wheel 14, rear walking wheel 8.

[0032] A guide rail 11 fixed on the frame 1, the upper loading surface 13 of the guide rail 11 is a straight line section, the lower loading surface 24 is a ship bottom shape, and the two ends of the upper loading surface 23 and the lower loading surface 24 are smooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com