High rigid exhibition table fastener for rapid connection of members

A fast connection, high rigidity technology, applied in the connection of rods, furniture connections, connecting components, etc., can solve problems such as insufficient support rigidity, and achieve the effect of correct positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

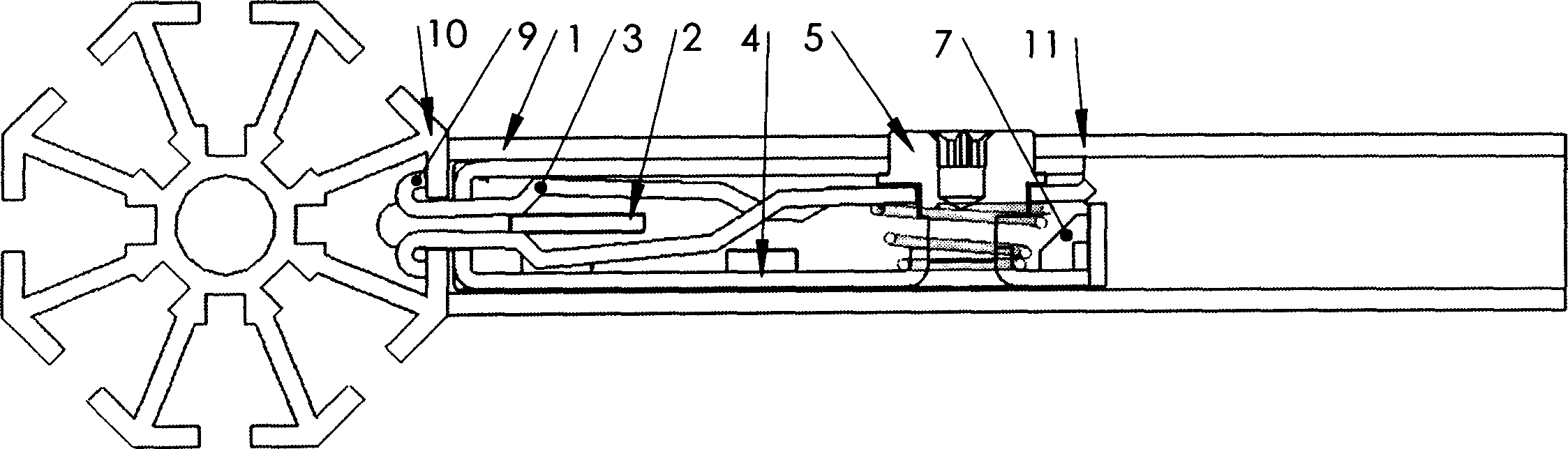

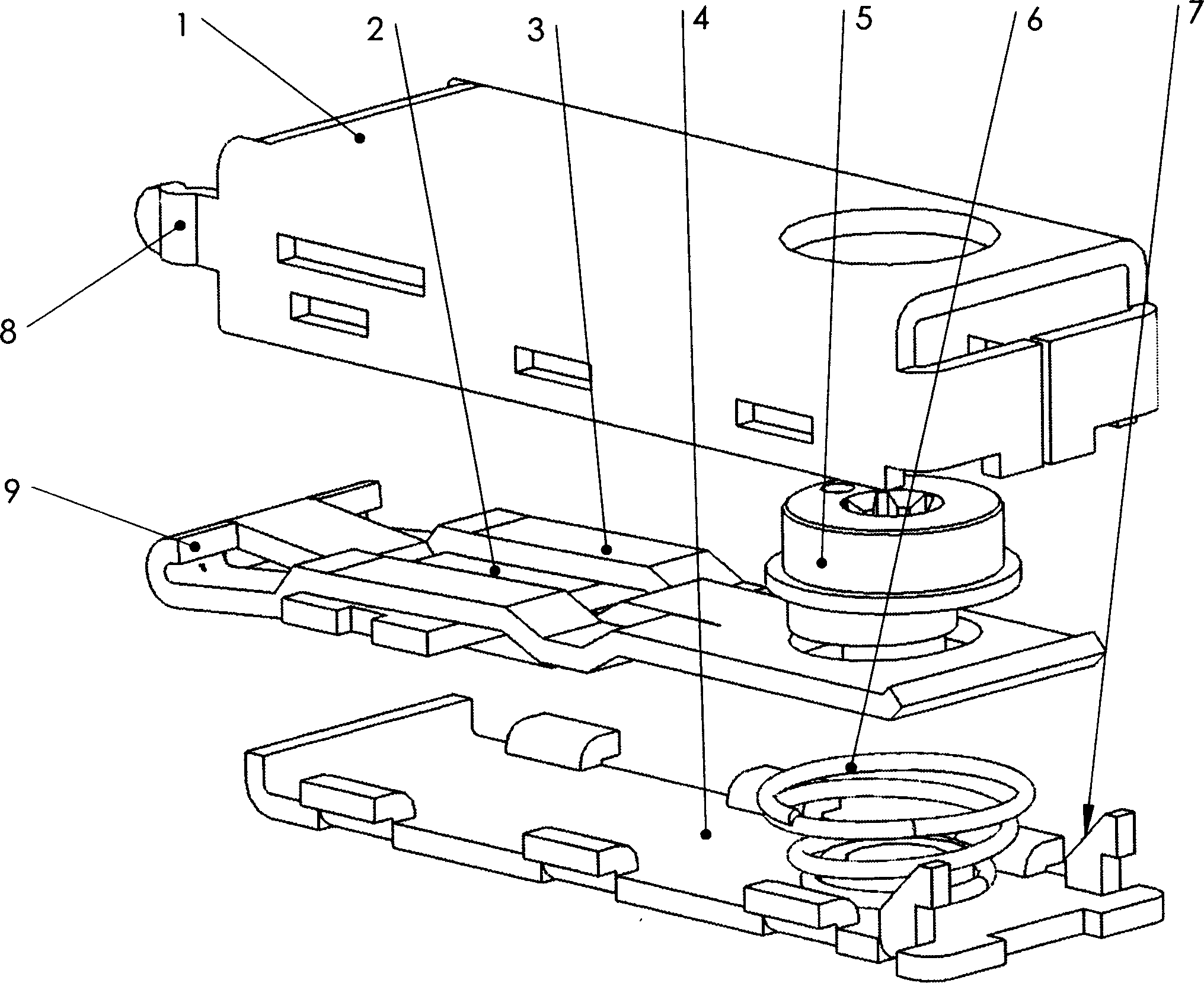

[0011] Referring to the accompanying drawings, its structure is composed of a shell 1, an inner support plate 2, a reed 3, a bottom plate 4, a spring 6 and an eccentric wheel 5; the shell 1 and the bottom plate 4 form a rectangular space, and the corresponding positions of the shell 1 and the bottom plate 4 There is a circular hole, and the eccentric wheel 5 is installed in this circular hole; the front end of the reed 3 is divided into three pieces, and the lock hooks used as the bayonet are respectively provided, and the lock hooks on both sides and the middle lock hook are opposite to each other. Curved, the rear part is a whole and has a non-circular hole, and the end has a bevel. The reed 3 is installed between the boss of the eccentric wheel 5 and the spring 6, and the inner support plate 2 is installed in the middle of the three separated front ends of the reed 3, and both sides are riveted on the shell. The non-circular hole on the reed 3 matches with the eccentric whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com