Integral prestress reinforced earth retaining wall construction method

A construction method and technology for retaining walls, which are applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of lack of anti-slip ability and slip hazards, and achieve structural optimization, stress condition optimization, and wall Uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

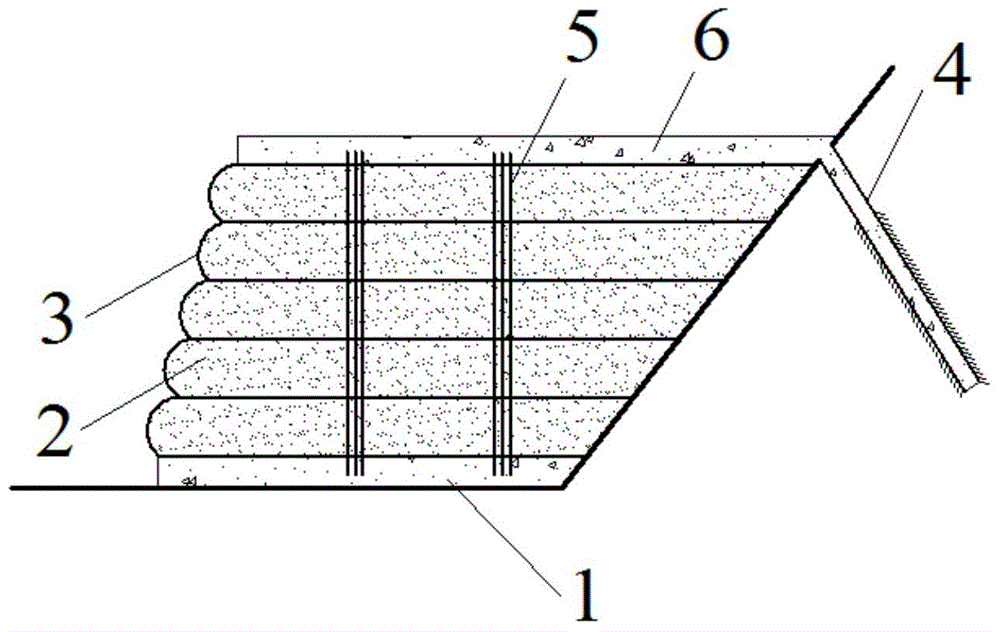

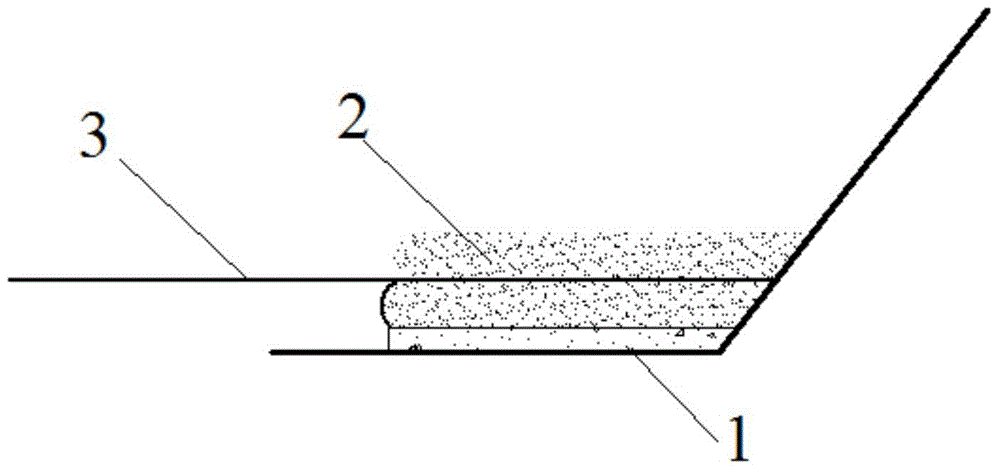

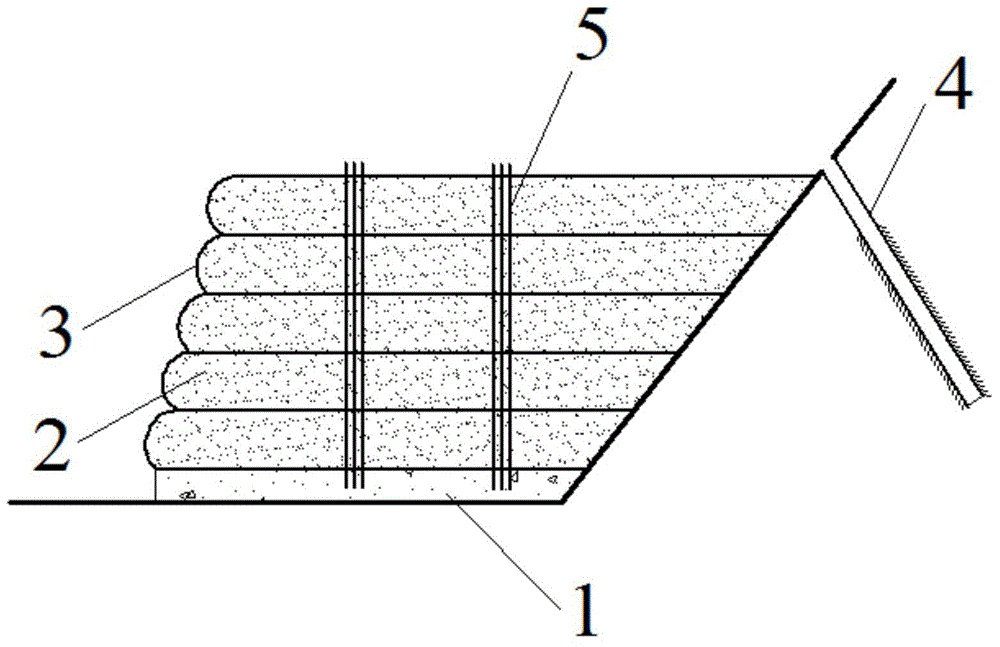

[0030] Such as Figure 1~3 as shown,

[0031] The construction method of the integral type prestressed reinforced retaining wall of the present invention comprises the following technical steps:

[0032] 1. Select a reasonable axis of the retaining wall to excavate the foundation groove of the retaining wall. One side of the foundation groove of the retaining wall is a slope, and the width of the excavated foundation groove can be determined according to the design width of the foundation of the retaining wall.

[0033] 2. Concrete bottom slab 1 of pouring retaining wall requires the design of the concrete bottom slab to meet the requirements of foundation bearing capacity.

[0034] 3. Install steel bars 5 perpendicular to the bottom plate on the bottom plate 1, and the length of the steel bars 5 exceeds the design elevation of the retaining wall.

[0035] 4. Lay a layer of geogrid or geotextile 3 on the upper surface of the solid part of the foundation groove. In the next ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com