Spring-propped bridge reinforcing structure

A technology for strengthening structures and supporting roofs, applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve the problems of increasing prestress effect, bridge damage, inconvenient bridge stress state, etc., achieve stable performance, large adjustment displacement, The effect of saving material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

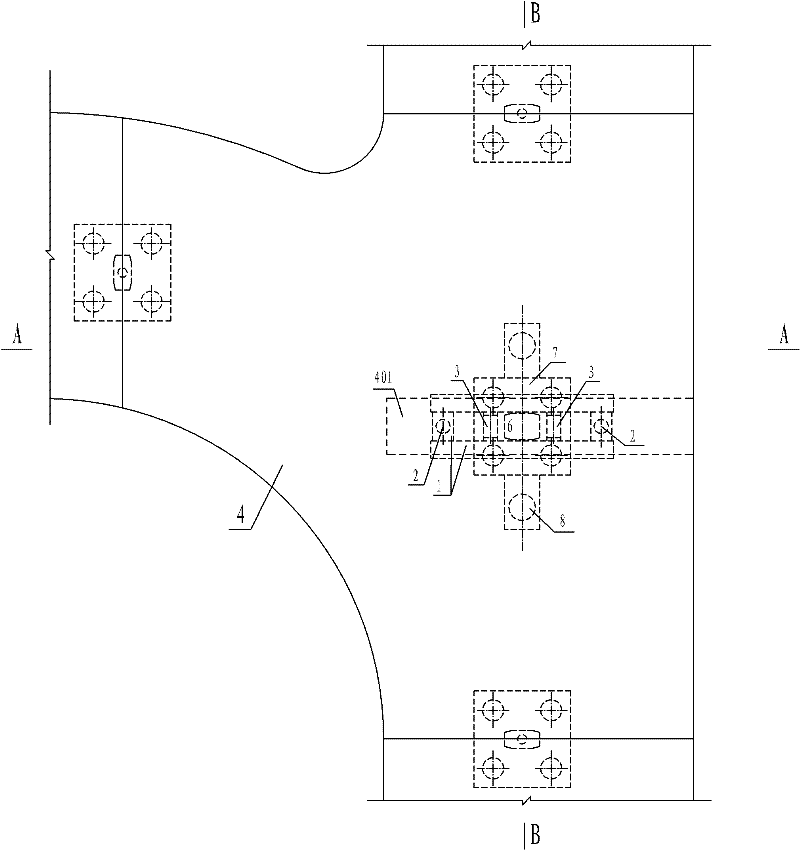

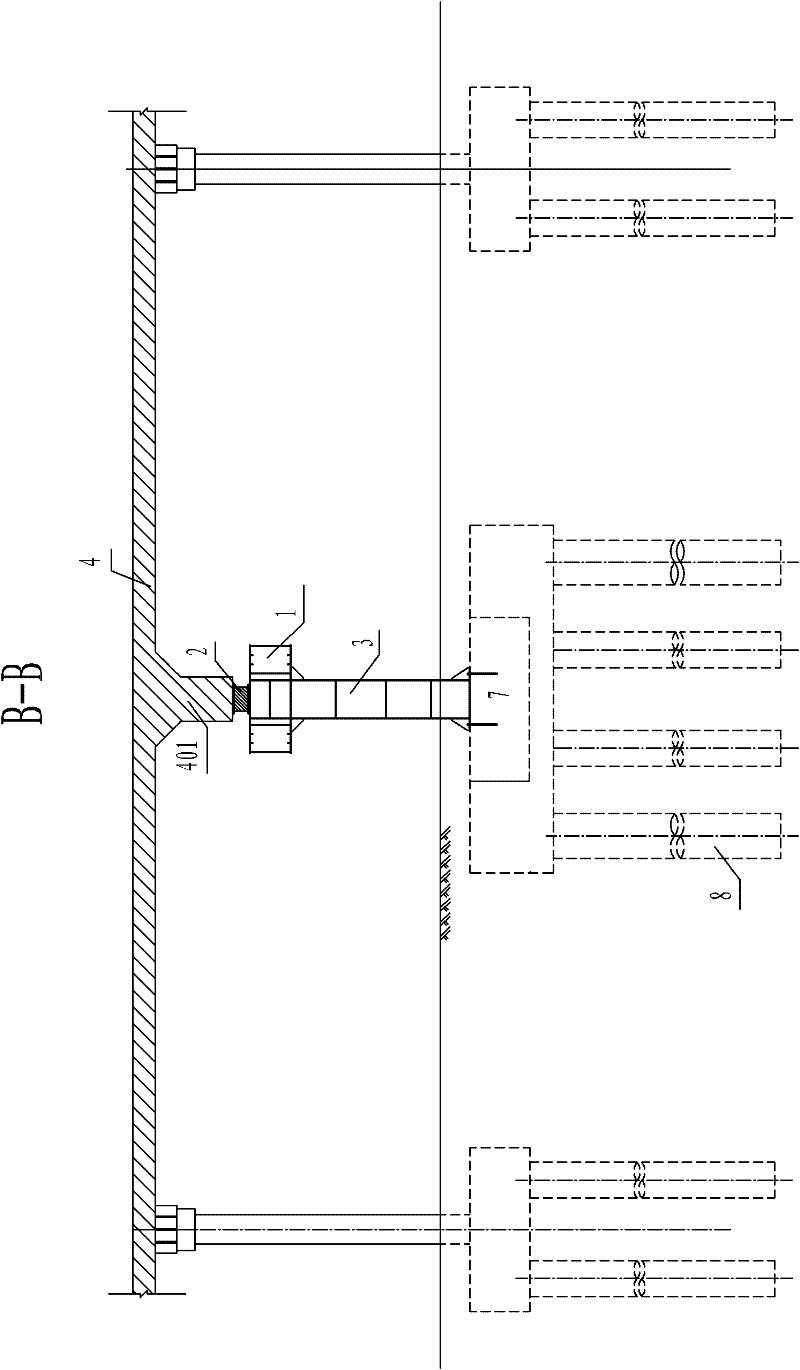

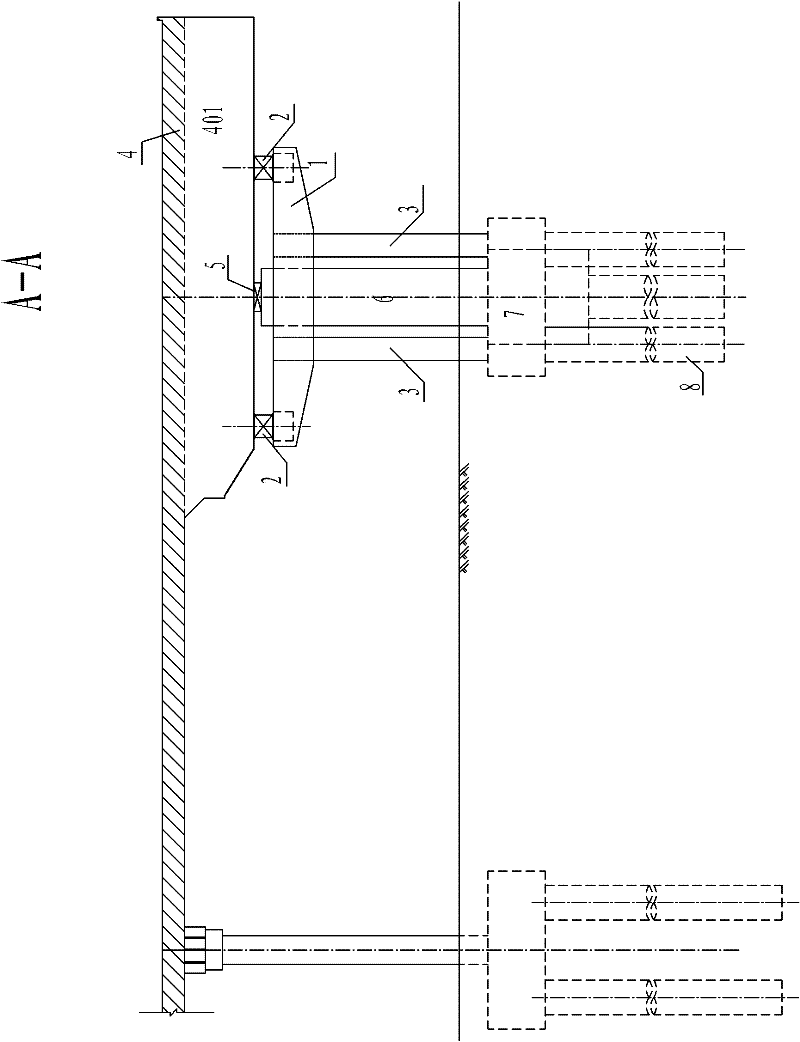

[0045] A kind of structure that the spring abutment reinforces the special-shaped plate of the reinforced bridge, such as Figure 1-3 As shown, it includes: the original pier column 6 is fixed on the cap 7, the original pier column 6 is supported on the special-shaped plate beam 401 of the bridge special-shaped plate 4 through the current support 5, and two units are arranged on the periphery of the original column 6 Spring abutment reinforcement structure, the unit spring abutment reinforcement structure is composed of two symmetrical π-shaped beam steel pier columns 3, π-shaped beam steel cover beam 1 and two symmetrical force-measuring adjustable bearings 2; The bottom plate of the two symmetrical π-shaped beam steel pier columns 3 is screwed to the bearing platform 7, the π-shaped beam is a symmetrical "π"-shaped structure, and the π-shaped beam steel cover beam 1 is symmetrically fixed on the two symmetrical The top of the π-shaped beam steel pier column 3 and the two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com