Mobile linear circulating-type acceleration loading test system

A technology of accelerated loading and testing system, applied in the direction of using repetitive force/pulsation force to test the strength of materials, etc., can solve the problems of low efficiency of accelerated loading test system, difficult environmental simulation conditions, complex structure, etc., to achieve convenient simulation of environmental conditions, Good stress conditions and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

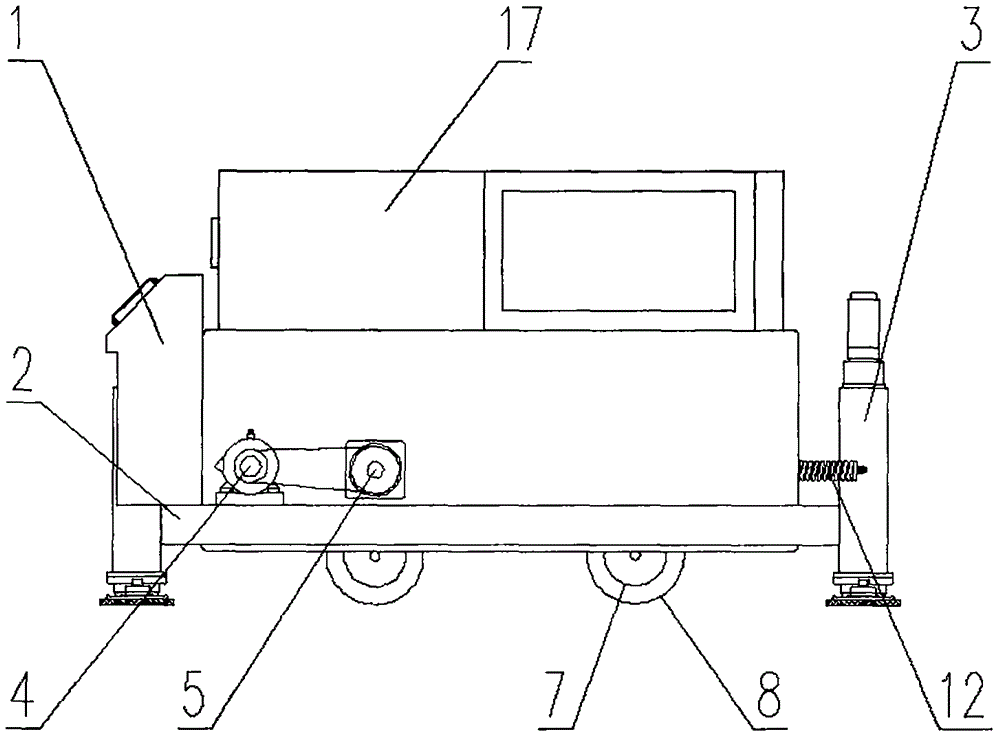

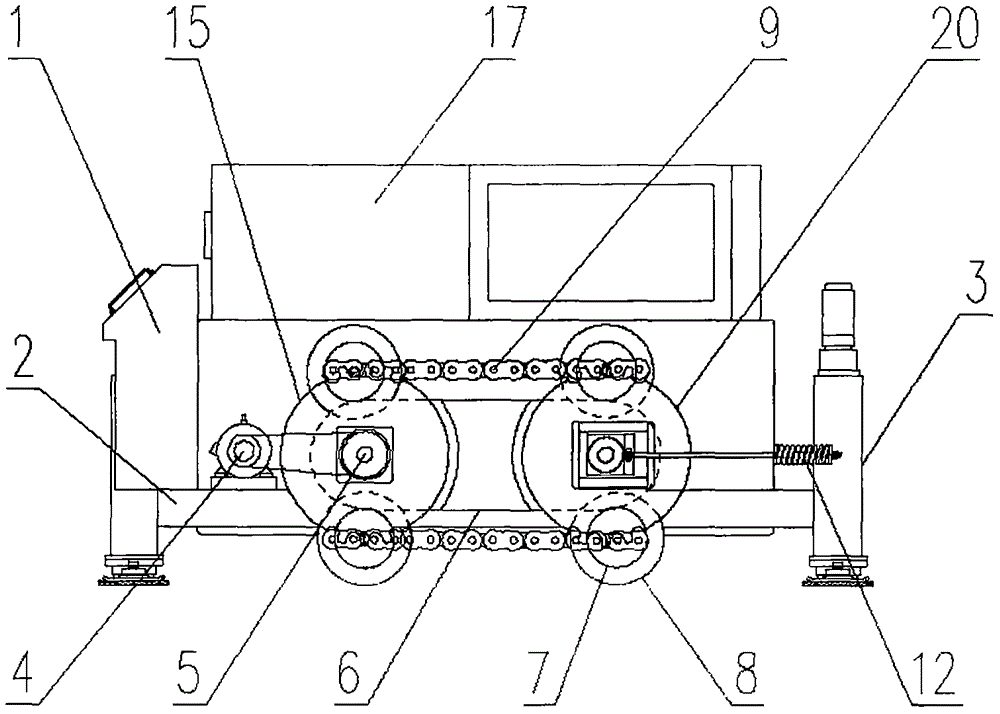

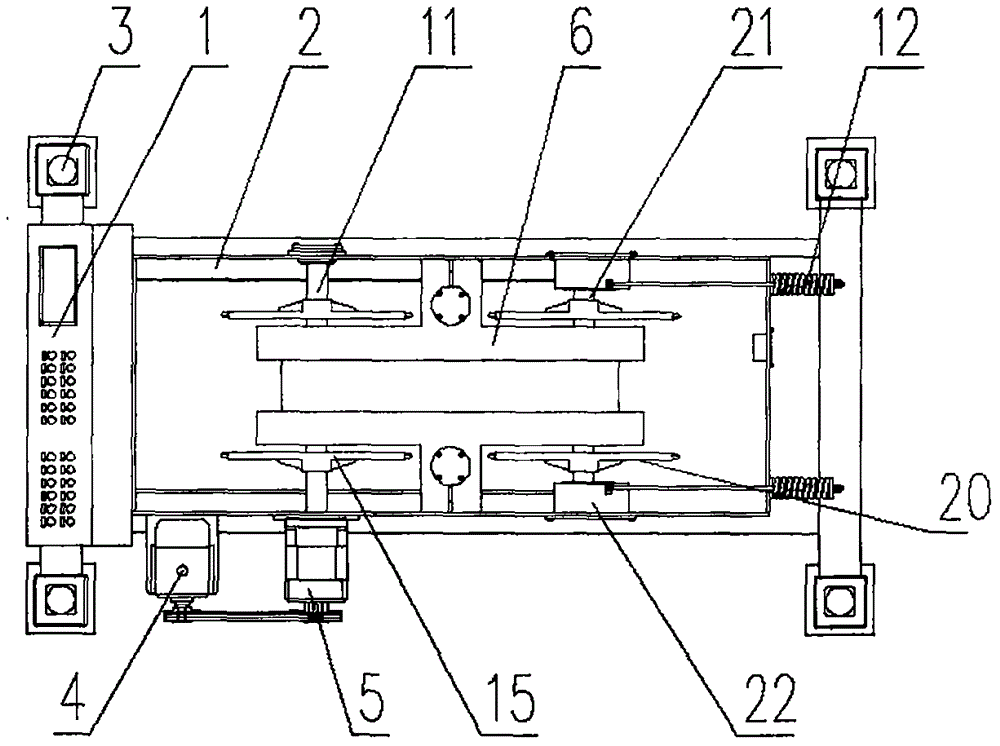

[0030] Attached below Figure 1-7 , a mobile linear circulation accelerated loading test system of the present invention will be described in detail below.

[0031] as attached figure 1 , 2 , 3, 4, and 6 shown, a kind of mobile linear cycle type accelerated loading test system of the present invention comprises:

[0032] A frame 2 for fixing guide rail 6, chain transmission pair and power mechanism;

[0033] A guide rail 6 fixed on the frame 2, the upper loading surface 13 of the guide rail 6 is a straight line section, the lower loading surface 16 is a ship bottom shape, and the two ends of the upper loading surface 13 and the lower loading surface 16 are smoothly transitioned through a curved section 14. The guide rail 6 is a box-type structure filled with shock-absorbing materials, and the straight section of the lower loading surface 16 is parallel to the test rolling road surface;

[0034] Four rolling wheel sets, each rolling wheel set includes two loading wheels 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com