Bracket assembly for lifting and supporting a lightweight foundation

a lightweight foundation and bracket technology, applied in the direction of foundation engineering, bulkheads/piles, construction, etc., can solve the problems of unstable structure supported on a shallow foundation or lightweight structure or foundation element, unstable structure, unstable structure, etc., to achieve easy and safe adjustment, reduce the moment of rotation and translation of weldments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

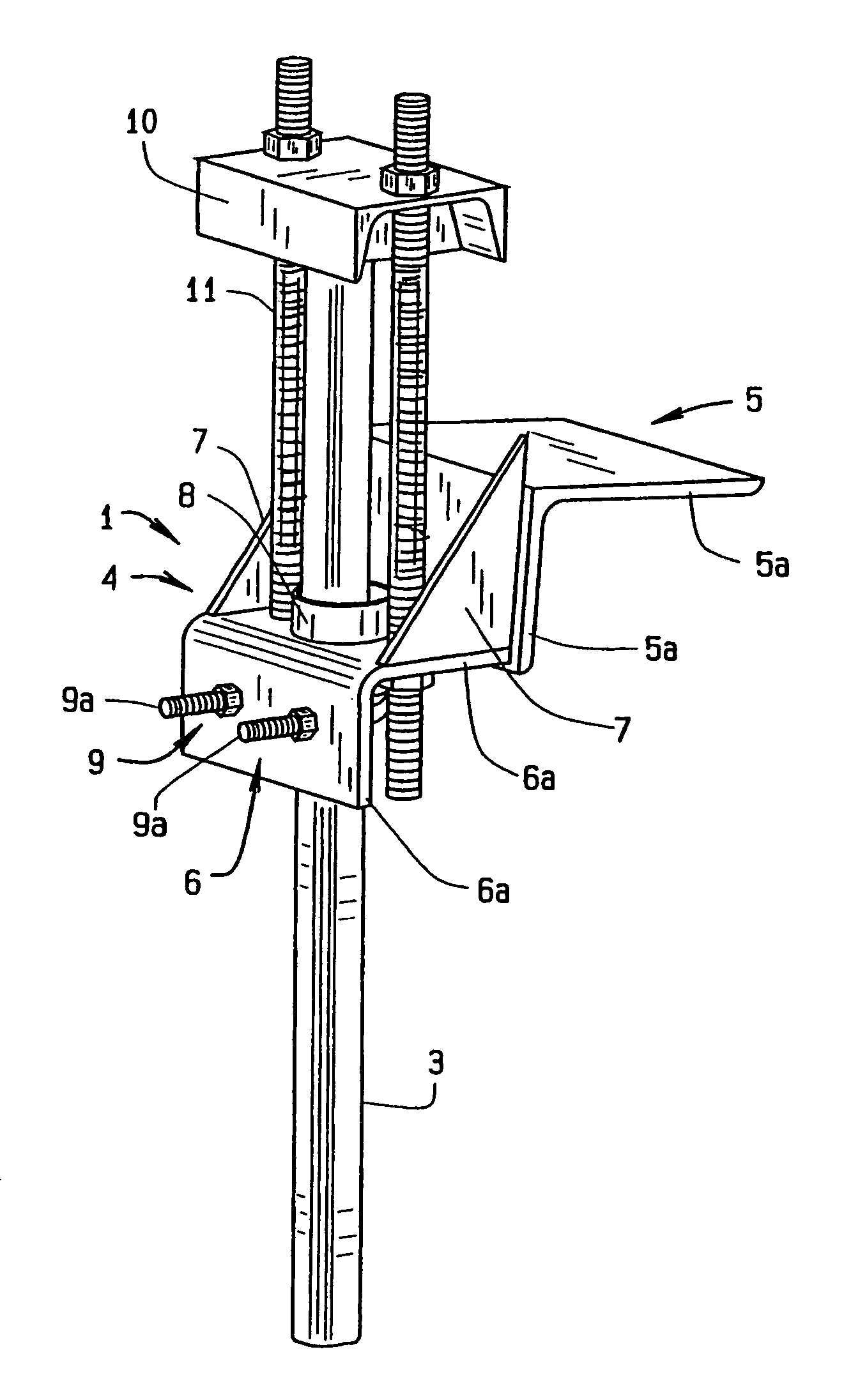

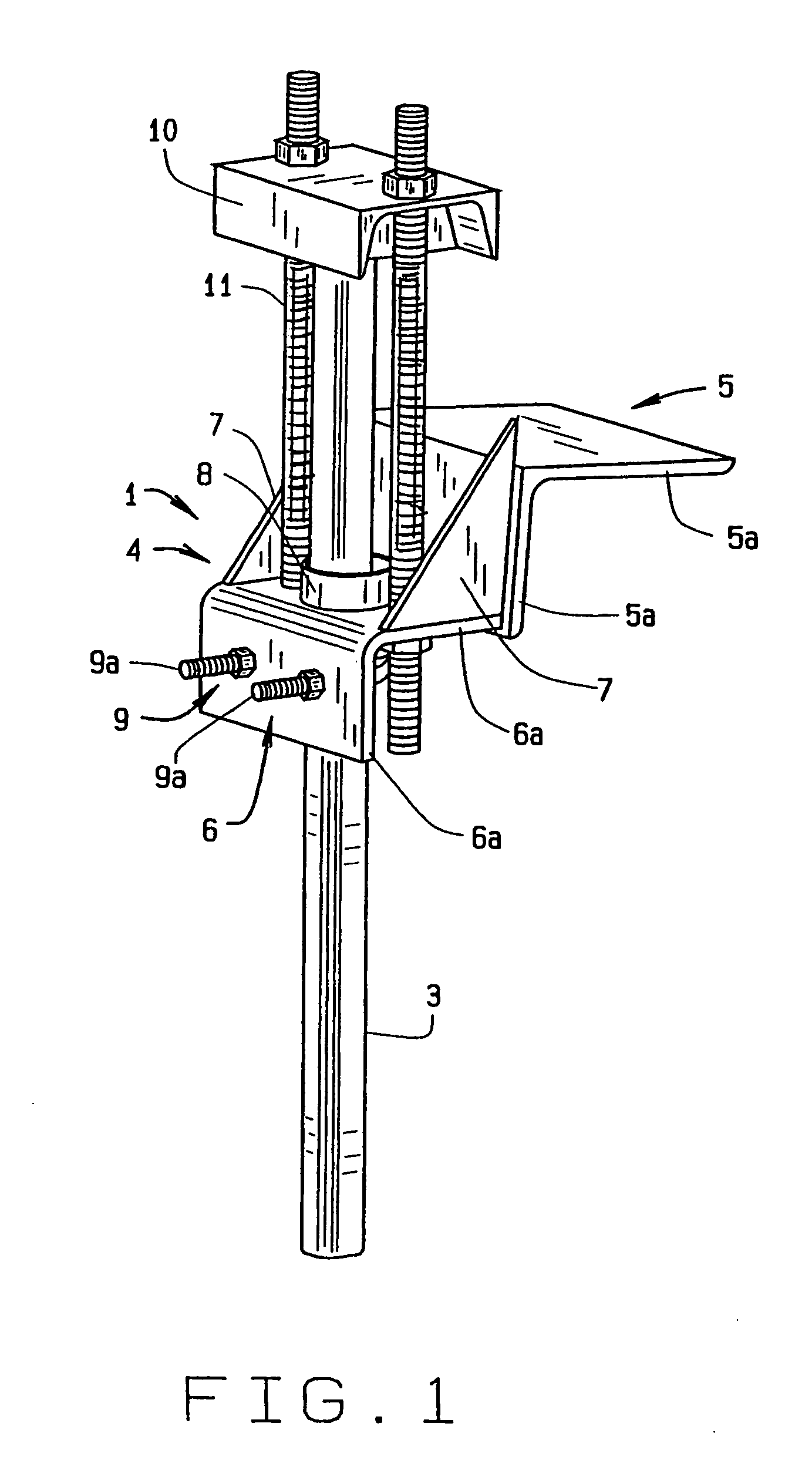

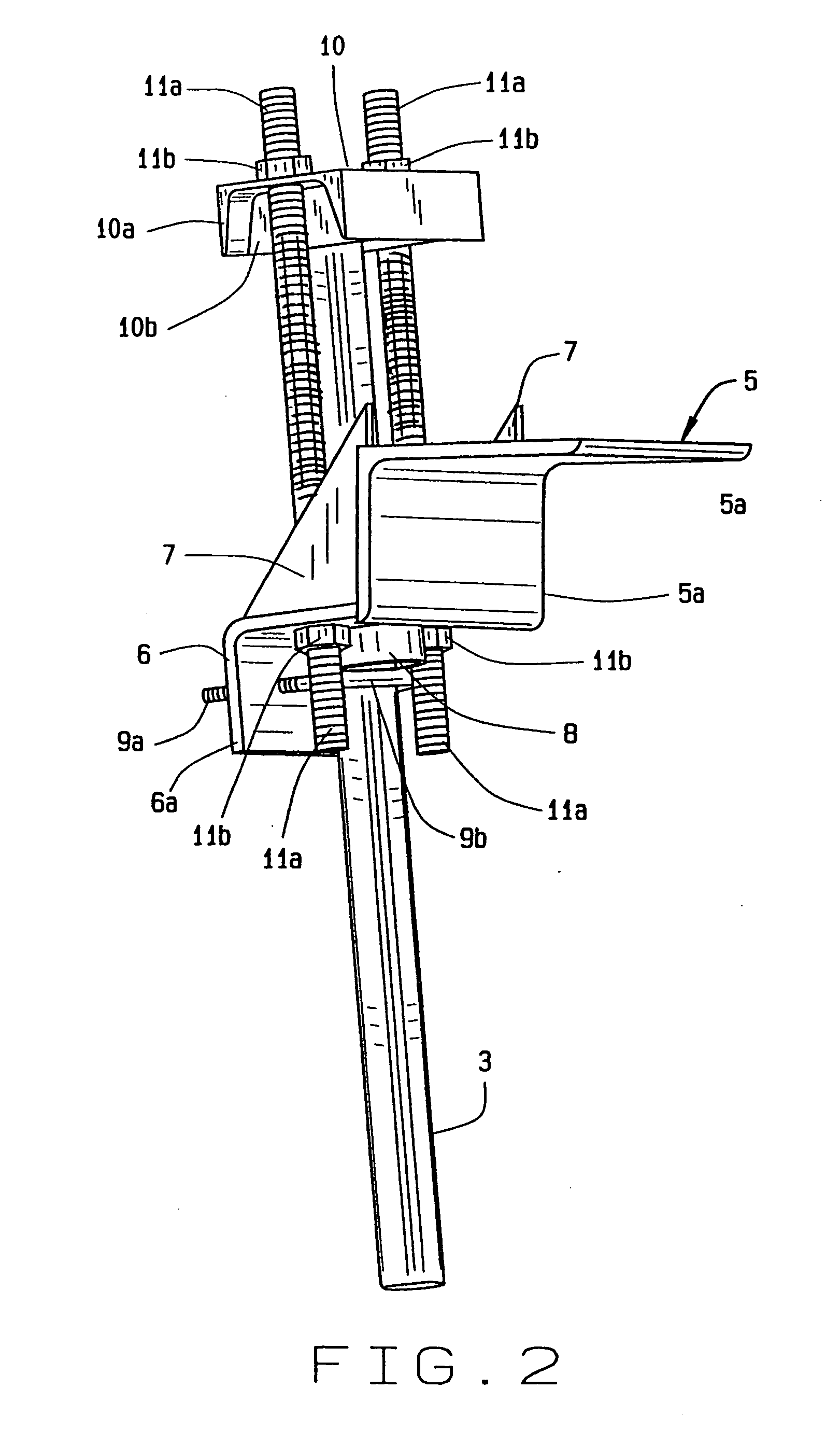

[0038] The present art overcomes the prior art limitations by providing a bracket assembly 1 that lifts and supports a lightweight structure or foundation element 2 with adjustable lifting and pile or deep foundation pier positioning hardware, that transfers lightweight structure or foundation element loads to piles or deep foundation piers 3 of various shapes and sizes, and that does not induce rotation of the bracket upon a pile or deep foundation pier. The present invention is installed upon a pile or deep foundation pier 3 adjacent to a foundation or lightweight structure or foundation element 2, and has limited rotation upon the pile or deep foundation pier due to the securing action of a U-shaped bolt 9. The U-shaped bolt 9 is oriented with threadably adjustable nuts upon stems facing away from the foundation 2 thus allowing an installer to make adjustments to the present invention safely without reaching beneath a supported structure or lightweight structure or foundation ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com