Method for primary support with corrugated steel plate and concrete combined structure taking place of steel grating

A technology of corrugated steel plate and combined structure, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of increasing cost, construction schedule limitation, and steel material consumption, so as to improve construction progress and reduce cross-section excavation , The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

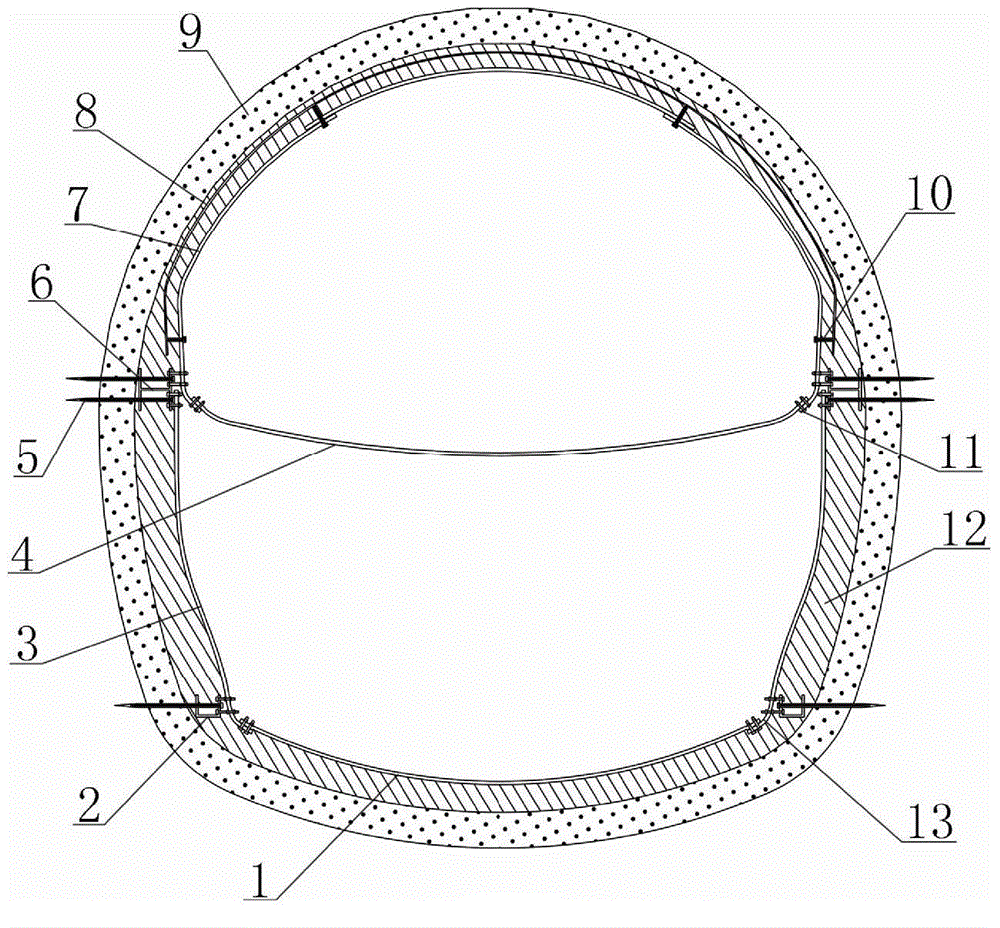

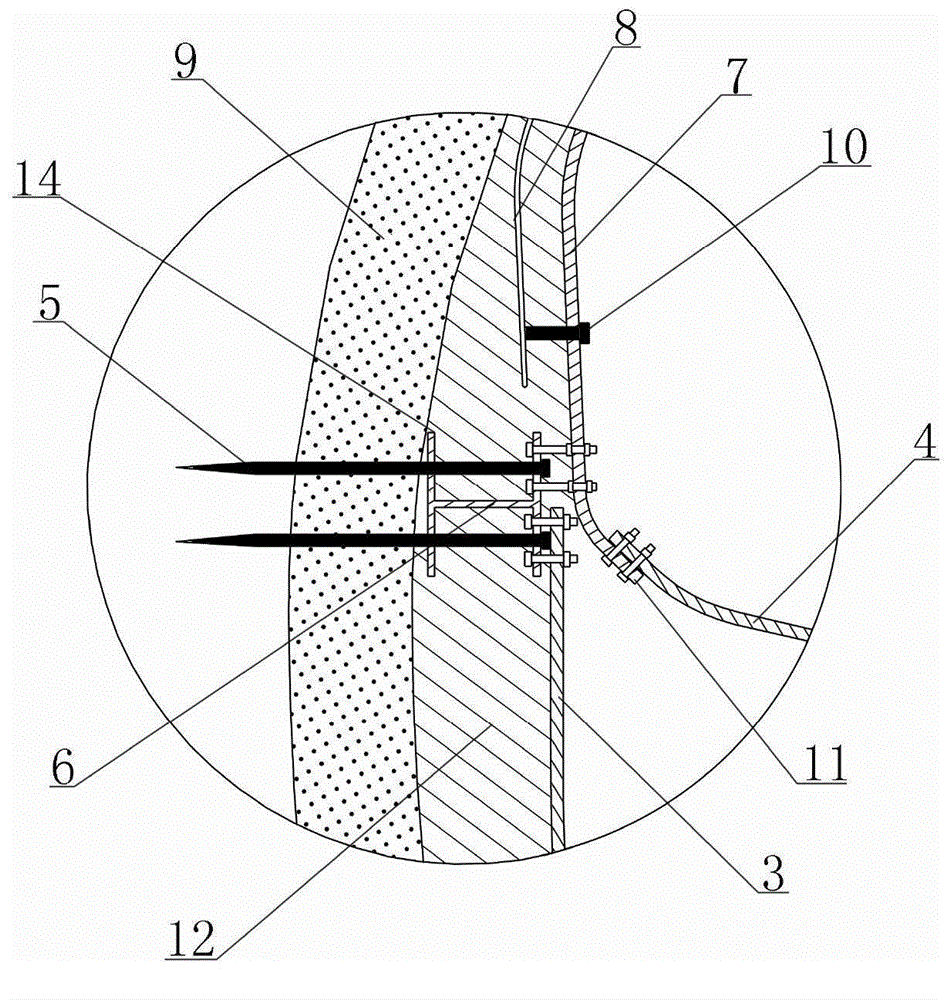

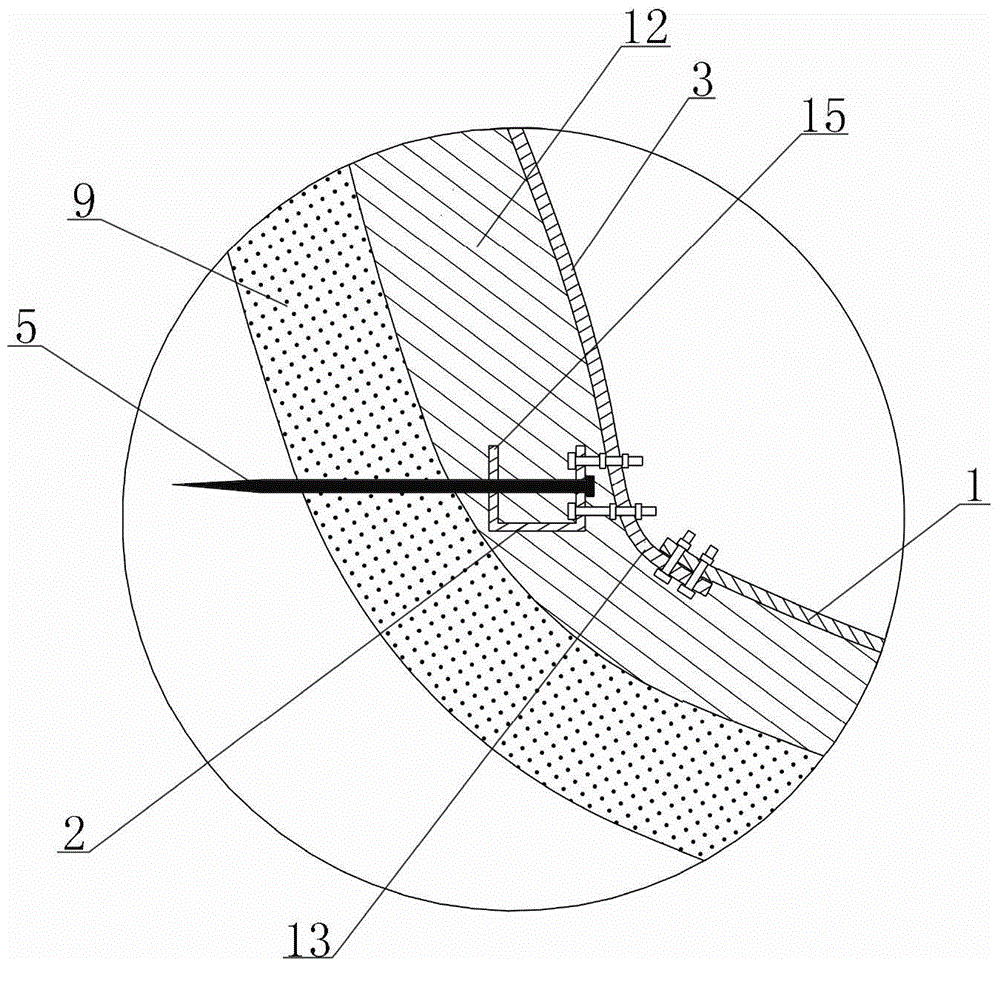

[0032] Such as figure 1 , 2 , 3, and 6, the initial support formed by the composite structure of corrugated steel plate and concrete is composed of the upper supporting corrugated plate 7, the side wall corrugated plate 3 and the inverted arch corrugated plate 1 to form a ring; the upper part The support corrugated plate 7 is made of three corrugated steel plates lapped and fixed by several bolts to form an arch. The two ends of the upper support corrugated plate 7 and the lap joint are respectively provided with long bolts 10 extending to the back side at the crests. A reinforcement mesh 8 is welded to the end of the long bolt 10 and is located on the back side of the upper support corrugated plate 7, and the reinforcement mesh 8 is kept parallel to the upper support corrugated plate 7; the two ends of the upper support corrugated plate 7 Temporary inverted arch lap joints 11 for connecting temporary inverted arch corrugated plates 4 are respectively reserved; two H-shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com