Full-section rock ripper for long-distance heavy-gradient inclined shaft

A large-slope, full-section technology, applied in the direction of shaft lining, shaft equipment, tunnel lining, etc., can solve the problems of large amounts of water gushing, large harmful gases, etc., and achieve the effect of increasing the speed of excavation, ensuring safety, and improving the efficiency of mucking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

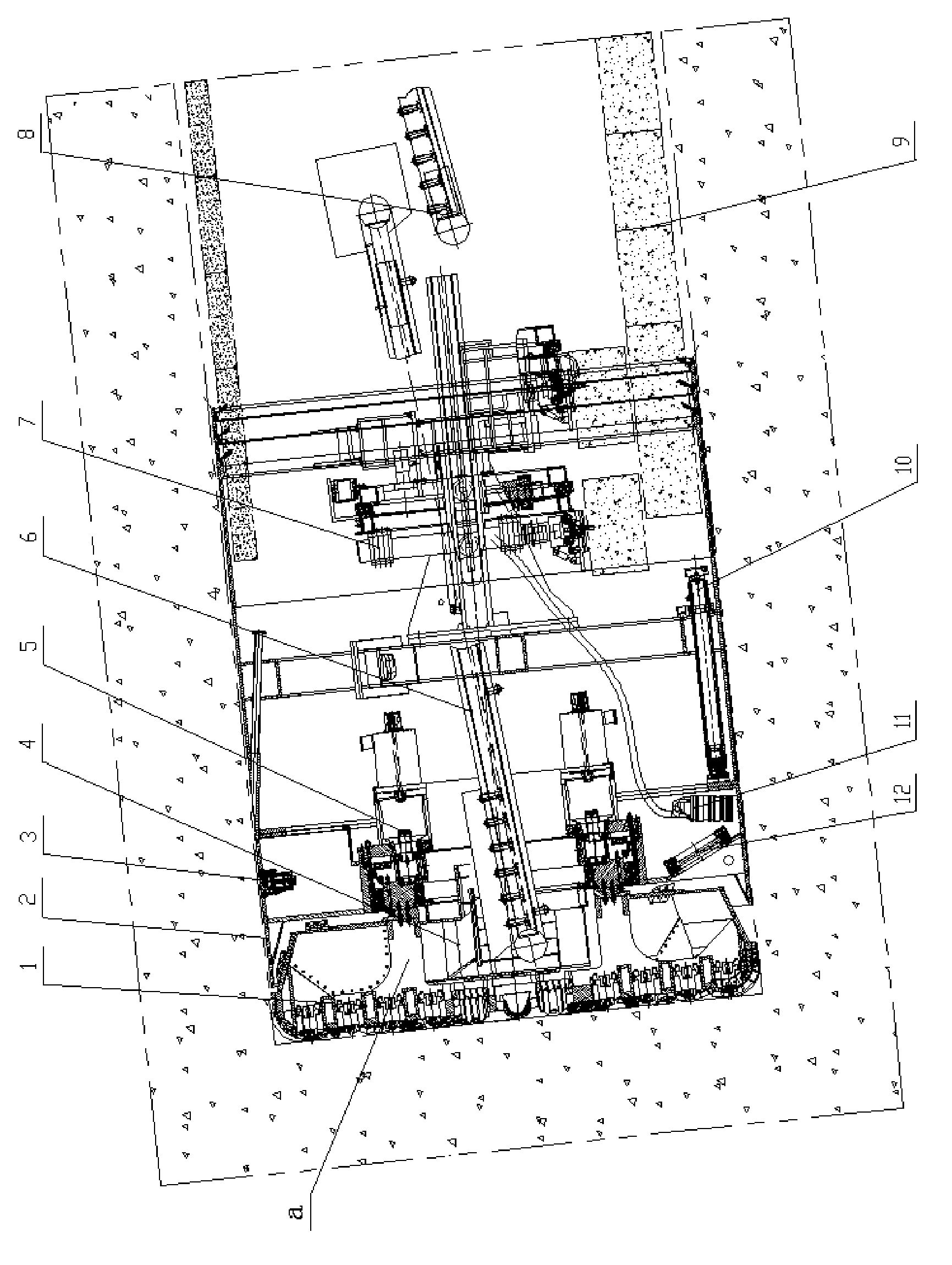

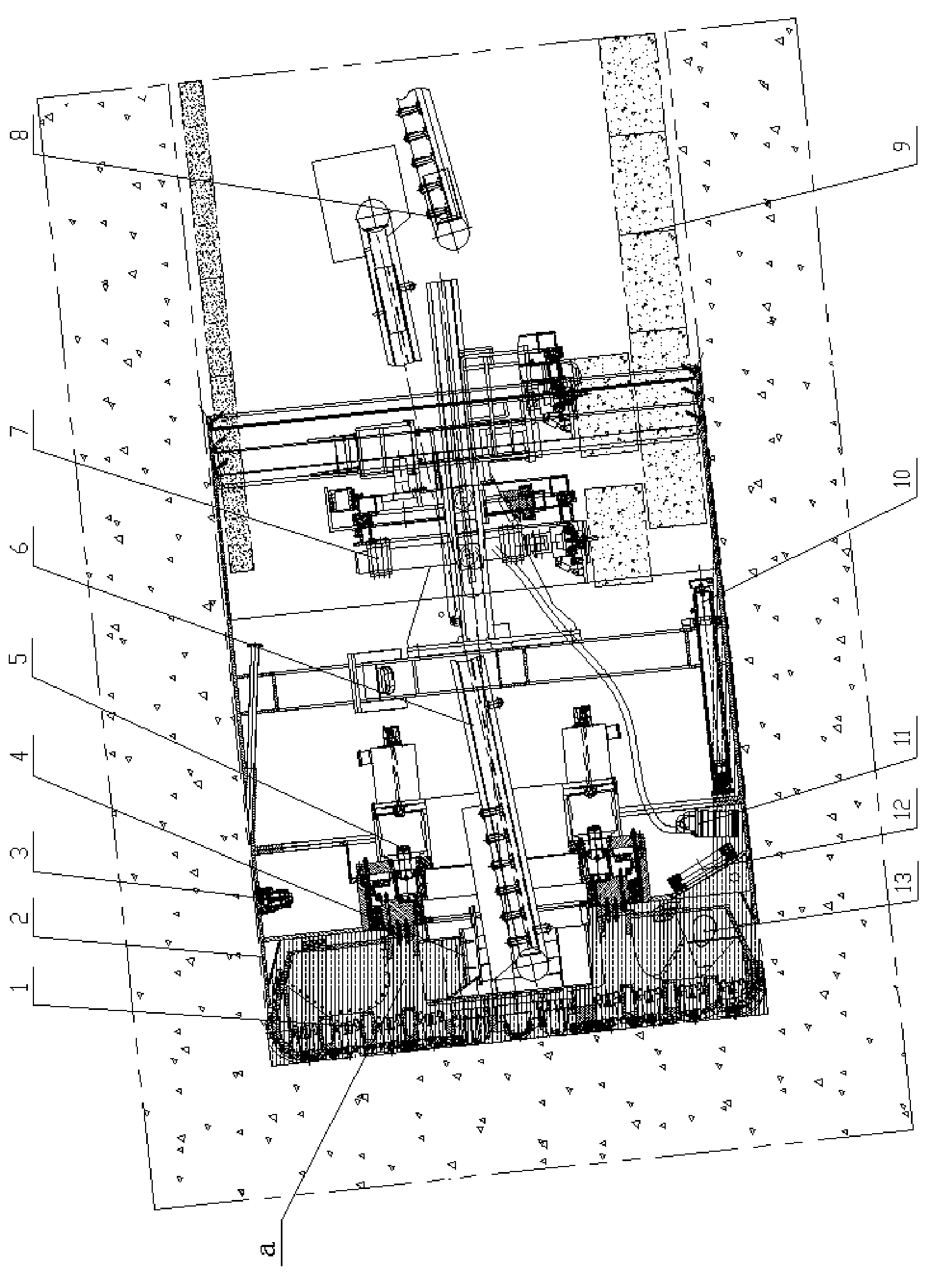

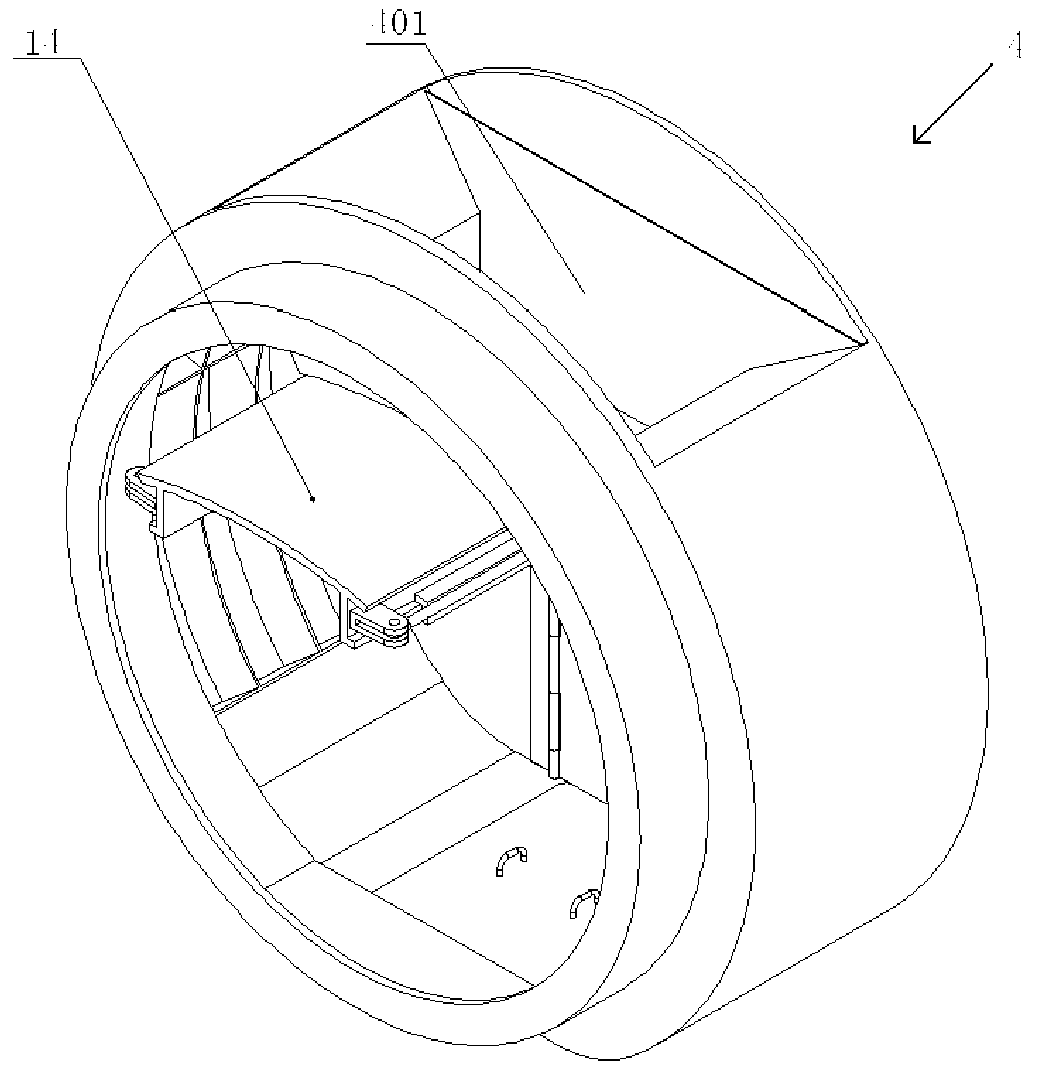

[0036] See figure 1 , figure 2 , a long-distance large-slope inclined shaft full-face rock tunneling machine, including a shield body 2 with airtight function and anti-rolling function, a machine head composed of a cutter head 1 and a main drive system 5 arranged at the front end of the shield body 2, and can be rotated in both directions. The cutter head 1 of the ballast, the excavation cabin a behind the cutter head 1, the airtight dreg receiving bucket 4 and the anti-surge door 12 arranged in the excavation cabin a, the stabilizer 3 installed on the top of the shield body, and the The propulsion oil cylinder 10 hinged with the machine head in the body 2, the explosion-proof drainage system 11, the explosion-proof ventilation and dust removal system 15, the host belt conveyor 6, and the segment assembly machine 7 located at the rear end of the shield body 2, and the host belt conveyor 6. The supporting belt conveyor 8 and the material quick reversing system connected by 6;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com