Bridge and construction method thereof

A construction method and bridge technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as difficulty in high-altitude construction, high safety risks, long bridge construction period, long construction period, etc., to shorten the construction period and labor High efficiency and the effect of improving construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Take a bridge with a deck height of more than 100 meters and a hard ground under the girder body, which is suitable for erecting temporary supports, and its construction method as an example:

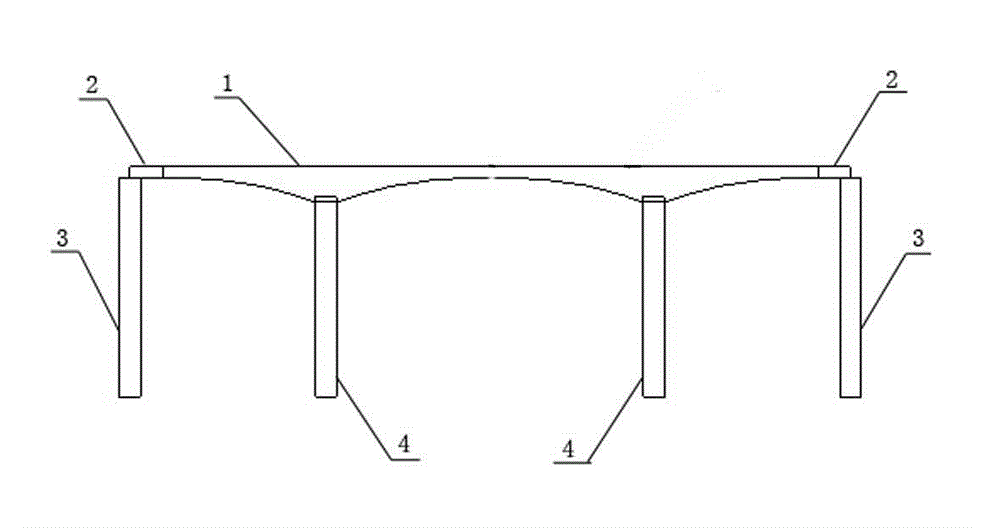

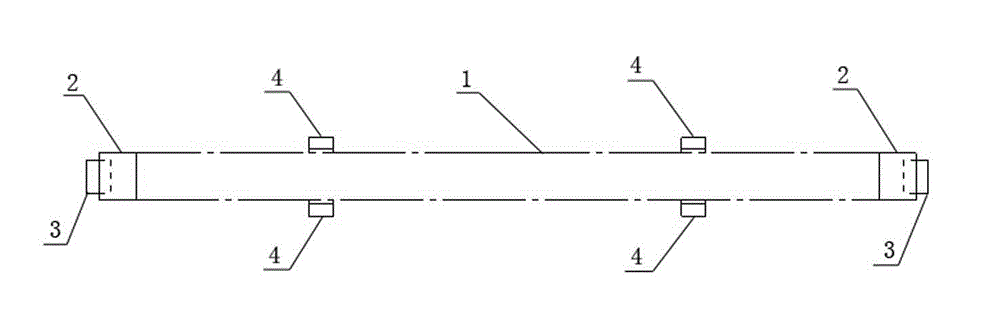

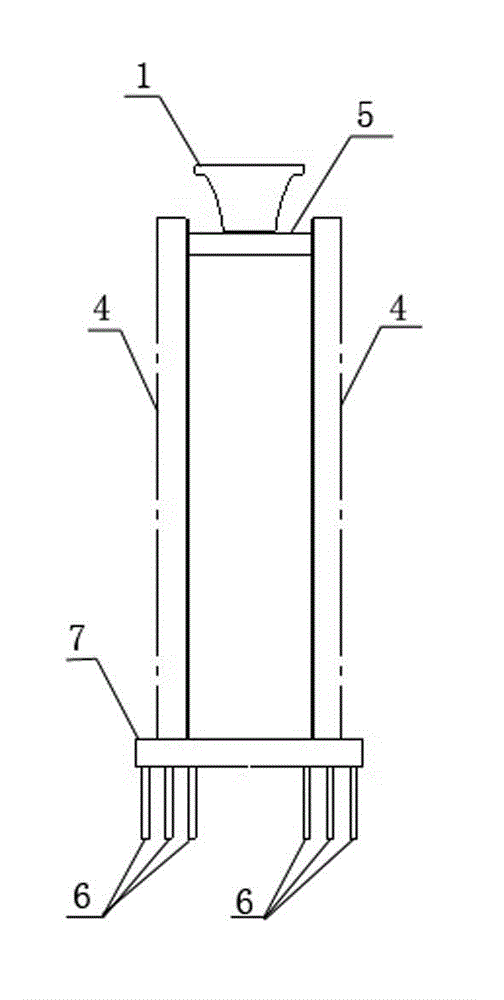

[0022] A bridge, comprising a pier and a girder body, the girder body comprising a prefabricated girder body 1, two side-span connecting sections 2 respectively connected to the head end and tail end of the prefabricated girder body 1, the pier comprising a prefabricated girder body The side piers 3 on the end side of the connecting section 2 and the main piers 4 symmetrically arranged on both sides of the end of the prefabricated beam body 1, and the two main piers 4 on both sides of the end of the prefabricated beam body 1 are connected with supporting prefabricated beams The load-bearing beam 5 of the body 1.

[0023] Bridge construction methods are:

[0024] A 1 6. Piling at the design position of the bridge pier 6.

[0025] The construction steps of the pile ...

Embodiment 2

[0042] Example 2: Take a bridge with a deck height of more than 100 meters, and the bridge below the bridge is river, soft foundation, deep valley, etc., which is not suitable for erecting temporary supports and its construction method as an example:

[0043] A bridge, comprising a pier and a girder body, the girder body comprising a prefabricated girder body 1, two side-span connecting sections 2 respectively connected to the head end and tail end of the prefabricated girder body 1, the pier comprising a prefabricated girder body The side piers 3 on the end side of the connecting section 2 and the main piers 4 symmetrically arranged on both sides of the end of the prefabricated beam body 1, and the two main piers 4 on both sides of the end of the prefabricated beam body 1 are connected with supporting prefabricated beams The load-bearing beam 5 of the body 1.

[0044] Bridge construction methods are:

[0045] A 1 6. Piling at the design position of the bridge pier 6.

[...

Embodiment 3

[0068] Take the bridge and its construction method when the deck of a certain bridge is more than 100 meters high and the foundation below the beam is the alternation of the river (or soft foundation) and the ground as an example: except for the construction method of the prefabricated beam body 1, the following construction method, other With embodiment 2. The construction of the prefabricated beam body adopts the combination of the bracket method and the cantilever pouring construction: the prefabricated beam body whose foundation is the ground section is constructed by the bracket method, and the prefabricated beam body whose foundation is the river section is constructed by the cantilever pouring construction, and the construction steps of the bracket method are the same as those in the embodiment 1. The construction steps of the cantilever pouring construction are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com