Shaft boring machine by open caisson method and construction method thereof

A technology for roadheaders and caissons, which is applied in vertical shaft equipment, sinking, earthwork drilling, etc. It can solve the problems of difficult disassembly, low degree of mechanization, and low work efficiency, so as to improve personnel safety and construction safety factor , The effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

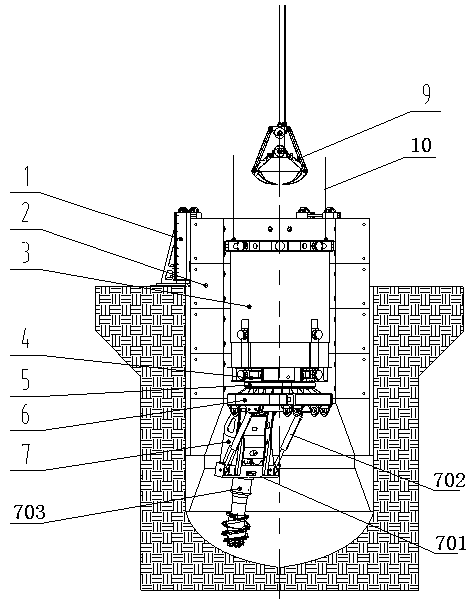

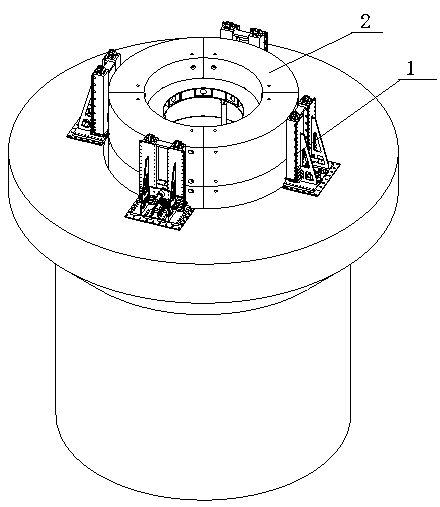

[0034] Example 1, such as Figure 1-3 As shown, a caisson shaft tunneling machine includes a tunneling system, a control and detection system, and a slag discharge system 9. A pipe joint pressure-lifting device 1 is provided on the wellhead ring beam on the ground, and the pipe joint pressure-lifting device can realize the whole The hoisting or pressurization of the wellbore has the characteristics of stable lifting or sinking, safety, adjustable speed, and convenient maintenance, so that the wellbore sinks smoothly. The excavation system includes a propulsion device 3, a slewing support 5, a slewing platform 6 and an excavation device 7. The upper part of the propulsion device 3 is connected to the hydraulic power system on the ground, and the propulsion device is used for radial stabilization and axial propulsion of the excavation system. . The lower part of the propulsion device 3 is provided with an equipment platform 4, the equipment platform 4 is connected with the slew...

Embodiment 2

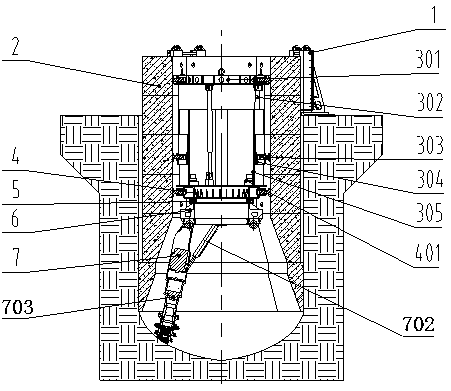

[0036] Example 2, such as Figure 4-6 As shown, a caisson method shaft boring machine, the first spreader mechanism includes several first stretcher cylinders 303, several second stretcher cylinders 306, and the second stretcher mechanism includes several third stretcher cylinders Oil cylinder 307, the first tensioning cylinder 303 is evenly arranged on the tensioning flange 301 along the circumferential direction, and the first tensioning cylinder 303 is stretched radially; the second tensioning cylinder 306 is evenly arranged on the outer cylinder 304 along the circumferential direction , and the second stretching cylinder 306 expands and contracts in the radial direction, and the third stretching cylinder 307 is evenly arranged on the outer circumference of the equipment platform 4 along the circumferential direction, and the third stretching cylinder 307 expands and contracts in the radial direction for supporting the equipment platform ; The first stretching oil cylinder ...

Embodiment 3

[0040] Embodiment 3, a construction method of a caisson shaft boring machine, comprising the following steps: S1: positioning the caisson to be excavated, leveling the site, hardening the surrounding parts of the wellhead, forming a ring beam at the wellhead, and forming a ring beam at the wellhead Fix the pipe joint pressure-lifting device on the upper part, and lay a cushion and level the blade foot part;

[0041] S2: The excavation device, slewing platform, slewing support, equipment platform, propulsion system, control and detection system are installed and debugged in sequence in the open space; since the installation and debugging of the mechanical structure of the roadheader has nothing to do with the pipe joints, this part can be installed in the submerged It is completed in advance before the well starts, so the preparation time for caisson operation is greatly saved and the production efficiency is improved.

[0042] S3: Install the blade foot pipe joint and the foun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com