Dual-shear force wall deformation slit formwork

A shear wall and deformation joint technology, applied in the field of double shear wall deformation joint formwork, can solve the problems of poor economy and long temporary construction period, and achieve the effects of reasonable structure, high reuse rate and flexible assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

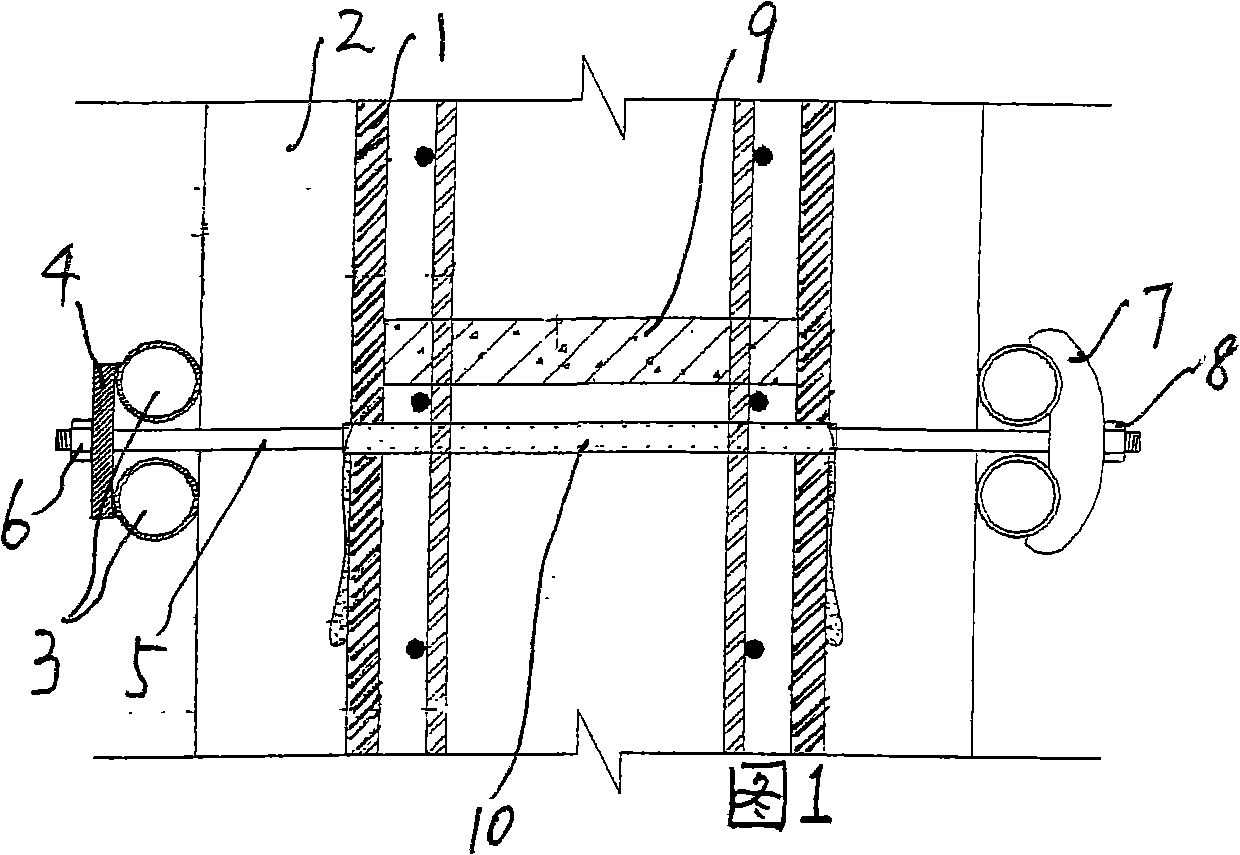

[0009] A double shear wall deformation joint formwork, including left and right side shaped formwork systems, each side shaped formwork system includes a panel 1, a vertical wooden keel 2 fixed with iron nails is installed on the outside of the panel 1, and a horizontal keel 3 is arranged outside the vertical wooden keel, The horizontal keel is made of steel pipes, and every two steel pipes are arranged next to each other. Steel plates 4 are welded on the two adjacent steel pipes in the formwork system on one side. The steel plates are provided with screw holes. Nut 6, on the horizontal keel of the shaped formwork system on the other side, the mountain-shaped clip 7 for fixing the opposite pull screw, the opposite pull screw 5 passes through the left and right side shaped formwork system, and is fixed by the nuts 6 and 8 on the above-mentioned steel plate 4 and the mountain-shaped clip 7 , Between the panels of the left and right side shaped formwork system, a wall panel thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com