Strengthening carbon fiber composite material and method for repairing defective pipeline

A composite material and pipeline repair technology, applied in the field of technology, can solve the problems of low elastic modulus and strength, inability to ensure that the composite sheet and the pipe body are closely fitted, and the improvement of the bearing capacity of the matrix is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

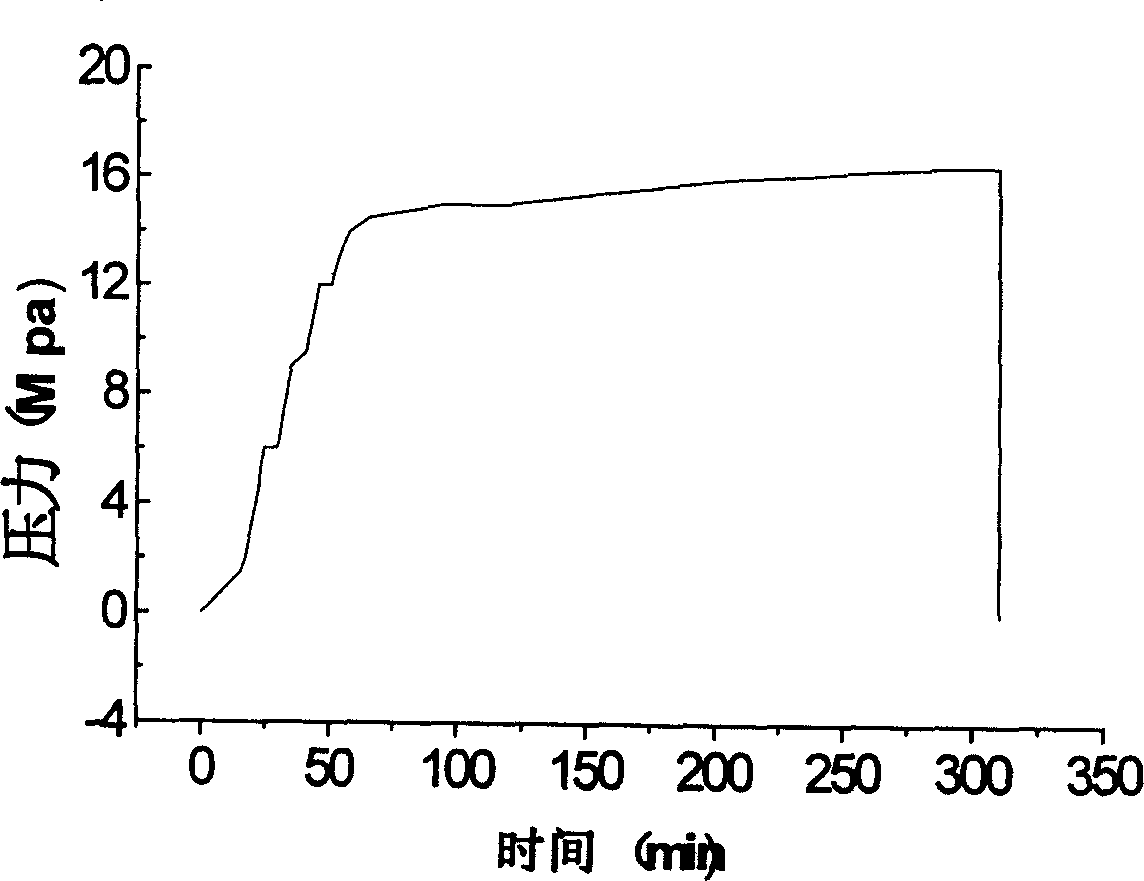

[0074] Embodiment 1: The technical solution of the present invention is evaluated by the hydraulic blasting test method

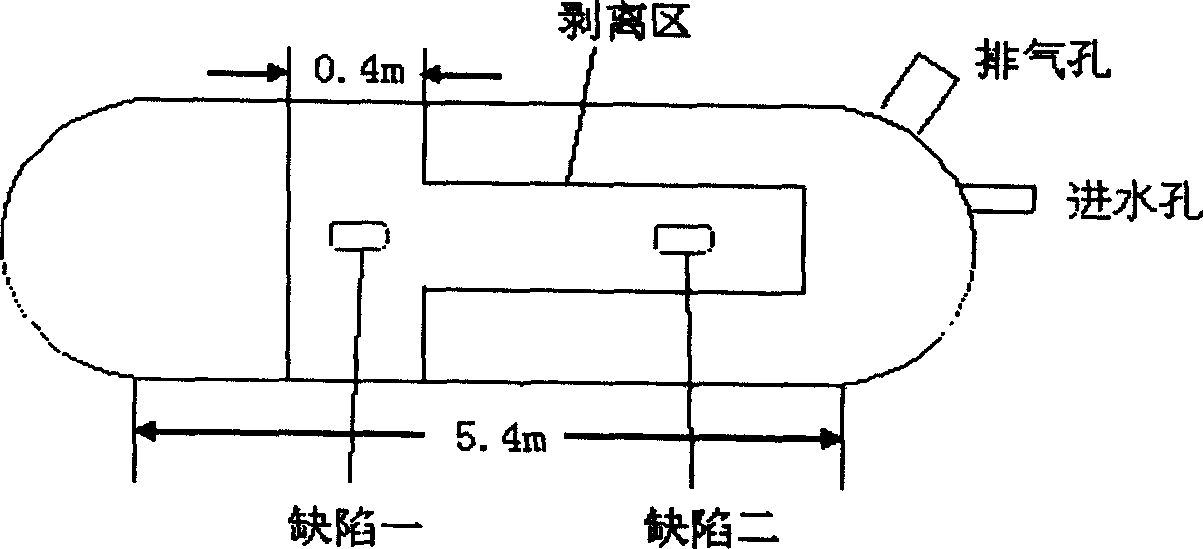

[0075] In order to test the implementation effect of this technology, taking φ660 gas transmission steel pipe as an example, the size of the defect that may exist in the gas transmission pipeline is simulated, and the technology is evaluated by hydraulic blasting test method. See Figure 1 for the test tube and its defects. The test process is as follows:

[0076] Cut a 5.45m pipe of the same size and material as the main line of a gas pipeline (the pipe is an X60 spiral welded pipe with a diameter of 660mm, a wall thickness of 8.7mm, and a design working pressure of 6.4Mpa), and leave The heads of the exhaust holes and water inlet holes are blocked (see Figure 2).

[0077] Clean the parts of the pipe body that need to be reinforced to remove the anti-corrosion layer, epoxy coating and dirt on the outer surface of the pipe, and make the surface treatment qu...

Embodiment 2

[0080] Example 2: Repair and reinforcement of natural gas pipeline defects

[0081] The field embodiment of the technology of the present invention is an example of defect reinforcement applied to the Shaanxi-Beijing gas pipeline. The defect at this place is reinforced by using the reinforcing material and repairing and reinforcing method described in the present invention. The specific implementation process is as follows:

[0082] 1. Excavation and surface cleaning of pipelines

[0083] The defect point of reinforcement construction is located somewhere in a certain section of Shaanxi-Beijing pipeline. The site is located on the edge of the desert, with a sandy soil structure, the surface water layer is relatively shallow, the buried depth of the pipeline is about 1300mm, and the external surface temperature of the pipeline is about 40°C. The tube body has three mechanical damages. One is an obvious mechanical scratch, 150mm long, 3.5mm deep, and the deepest width is 20m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com