Technology for hoisting strip-shaped inclined steel structures in place through single crane

A single crane and steel structure technology, applied in the field of steel structure construction, to achieve the effect of reducing construction costs, improving efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

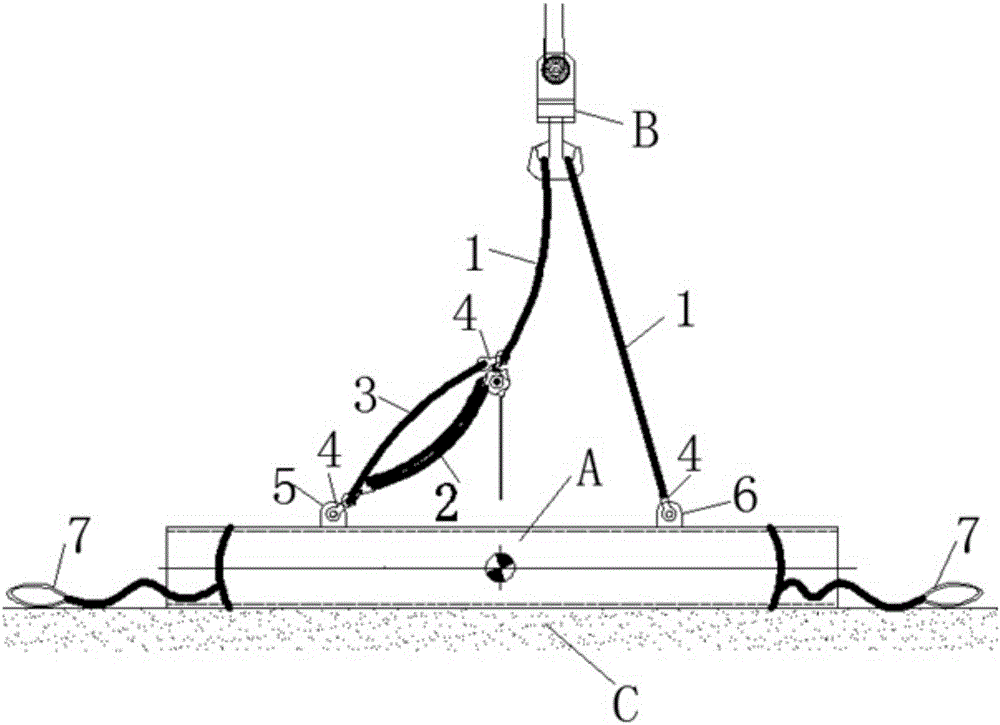

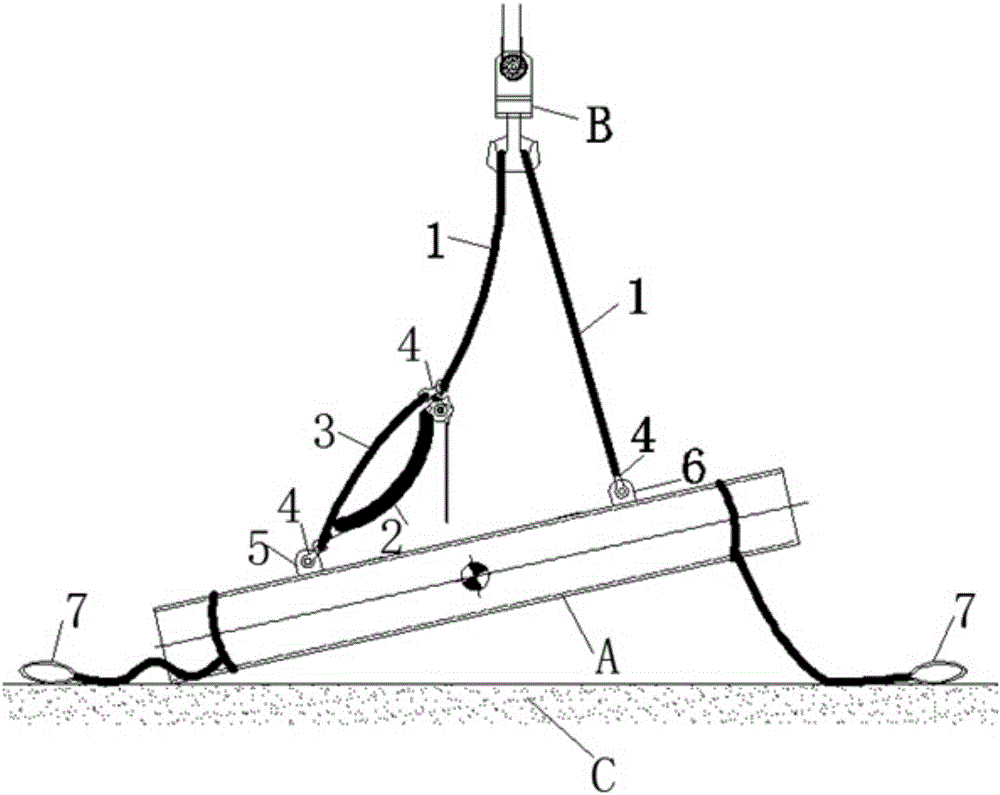

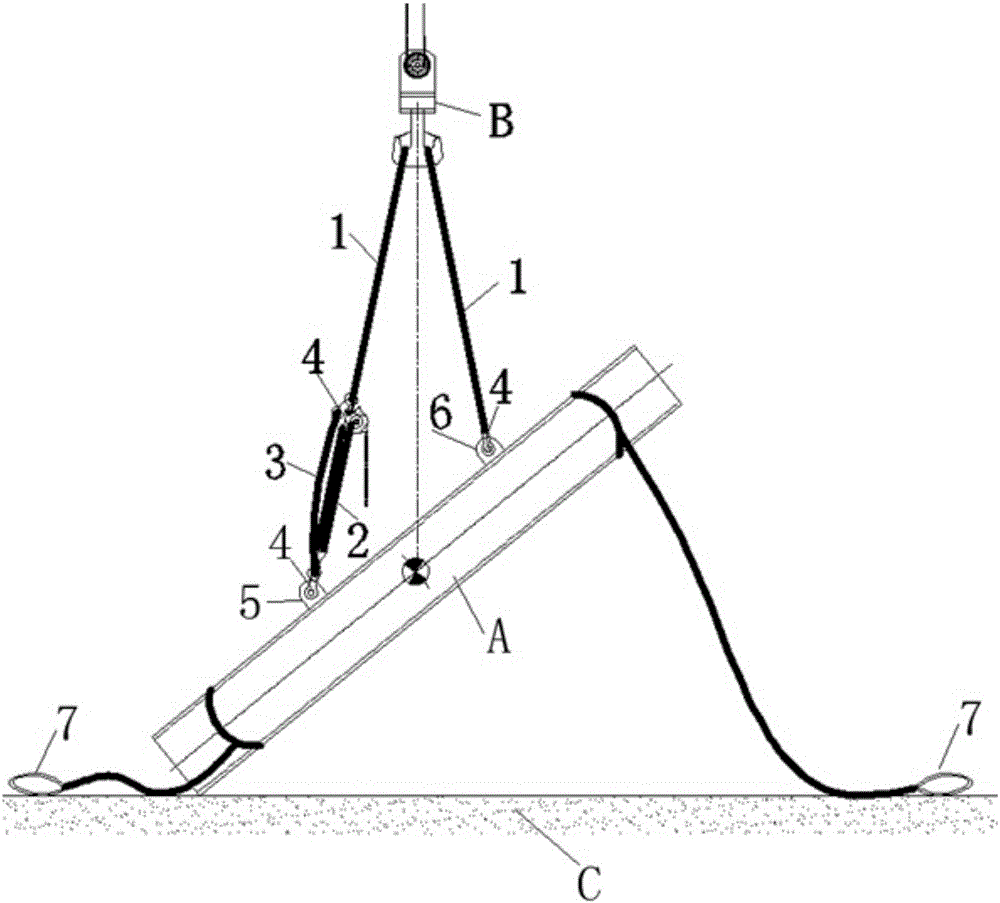

[0026] Such as figure 1 — Figure 5 Shown, the present invention adopts following steps:

[0027] The first step: measure the size of the inclined tie bar A that needs to be hoisted, and calculate the weight and center of gravity position of the inclined tie bar A according to the geometric dimensions;

[0028] The second step: prefabricated welding low hanging point 5 and high hanging point 6; and installing the main board of low hanging point 5 and high hanging point 6 along the length direction of the inclined reinforcement A, the positions of low hanging point 5 and high hanging point 6 can be determined according to Make local adjustments according to the actual situation;

[0029] The above-mentioned low-level lifting point 5 and high-level lifting point 6 are plate-type, and the position of the lifting point is 1 / 4 of the total length on both sides of the center of gravity of the inclined tie bar A.

[0030] The third step: arranging several slings (two in this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com